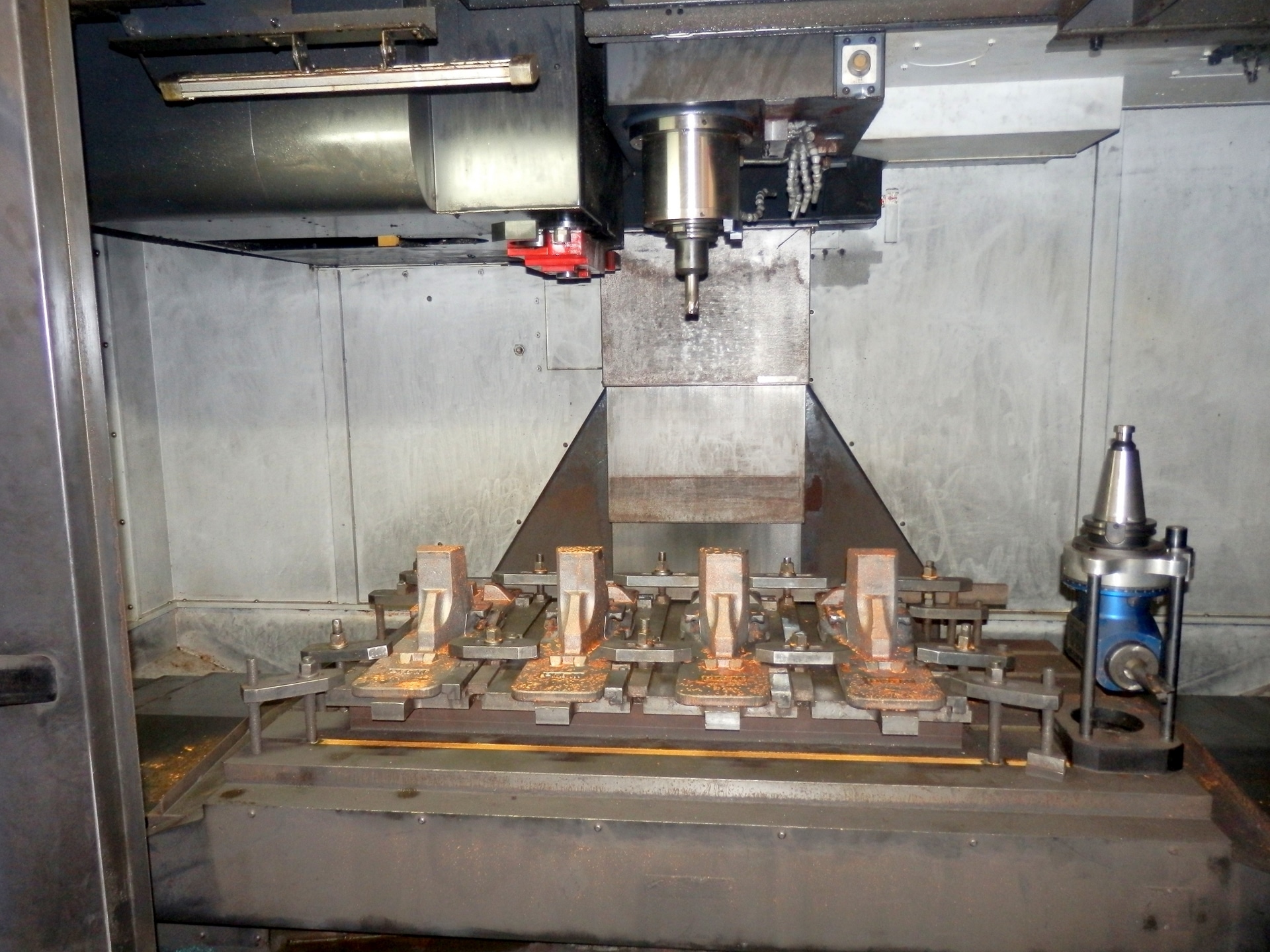

The DOOSAN MYNX 6500/50 machining center was built in 2015, and the installation was in 2017. The milling center is equipped with a Fanuc CNC control, which ensures easy programming of the machine and a chip receiver.

Technical parameters of the DOOSAN MYNX 6500/50 CNC milling machine

– CNC control: FANUC 0 iMD + Manual Guide

– processing range: 650 x 1200 mm

– cone: 50

– table dimensions: 1400 x 670 mm

– table load capacity: 1000 kg

– T-slot: 5-125 x 18 H8

– aP30 spindle motor: 18.5 / 15 kW

– spindle speed range: 6000 rpm.

– maximum spindle torque: 307 Nm

– spindle taper: ISO # 50, 7/24

– maximum feed, X axis: 1270 mm

– maximum feed, Y axis: 670 mm

– maximum feed, Z axis: 625 mm

– rapid traverse, X axis: 30 m / min.

– rapid feed, Y axis: 30 m / min.

– rapid feed, Z axis: 24 m / min.

– servo motor, X axis: 4 kW

– servo motor, Y axis: 4 kW

– servo motor, Z axis: 7 kW

Other technical data:

– compressed air: 0.54 MPa x 250 N l / min.

– power demand: 3 Ph – AC220V / 60 Hz x 42.2 kVA

– center dimensions: 3350 x 2674 x 2840 mm

– machine weight: 9000 kg

– coolant tank capacity: 380 l

– coolant pump capacity: 1.5 kW, 1.9 Pa x 29.1 l / min.

– oil tank capacity: 1.4 l

– hydraulic pump capacity (60 Hz): 1.67 MPa x 0.15 l / min.

Tool magazine used in DOOSAN MYNX

– tool magazine: 30EA

– tool holders: DIN 40

– maximum diameter of tools: 80 mm (when the neighboring station is free 125 mm)

– tool length: 300 mm

– maximum tool weight: 8 kg

– position change time, tool to tool: 1.3 s

– change of position time, chip to chip: 3.7 s

Description of the DOOSAN MYNX 6500/50 milling center operation

The machine tools are cooled by a spindle and a spray system with coolant. The machine drive is transmitted from the engine (power 18.5 kW) through a two-stage gear transmission. Feeds and revolutions are smoothly changed by means of inverters. The Teo-Step (two-stage) gearbox generates extremely high torque for a wide range of heavy-duty machining. The Big Plus system allows for simultaneous double contact of the tool holder on the conical side and the spindle face.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano