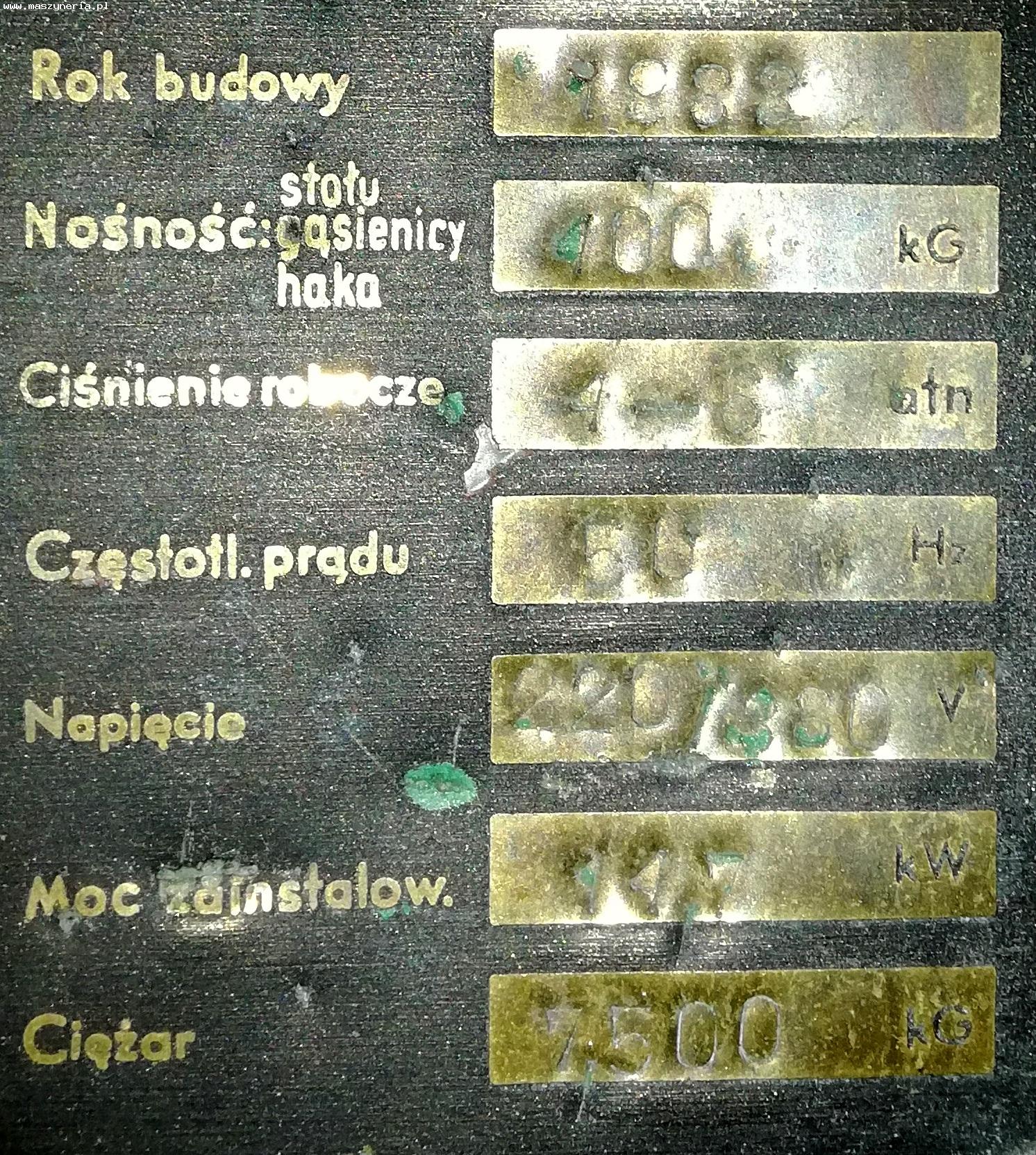

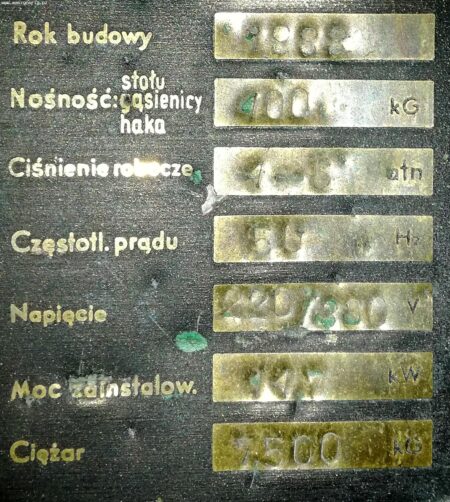

DOZAMET OWT 400A fettling plant of Polish production was built in 1988 and its purpose is cleaning of iron and steel castings. The cleaning process takes place in a closed working chamber where the blades of the impeller make use of shot blasting and the mutual rubbing of castings. Castings subjected to the process may be up to 400 mm long, 400 mm wide, 400 mm high and weigh up to 400 kg.

The DOZAMET OWT 400A machine consists of:

– working chamber,

– screw with sieve and drive,

– suction pipes,

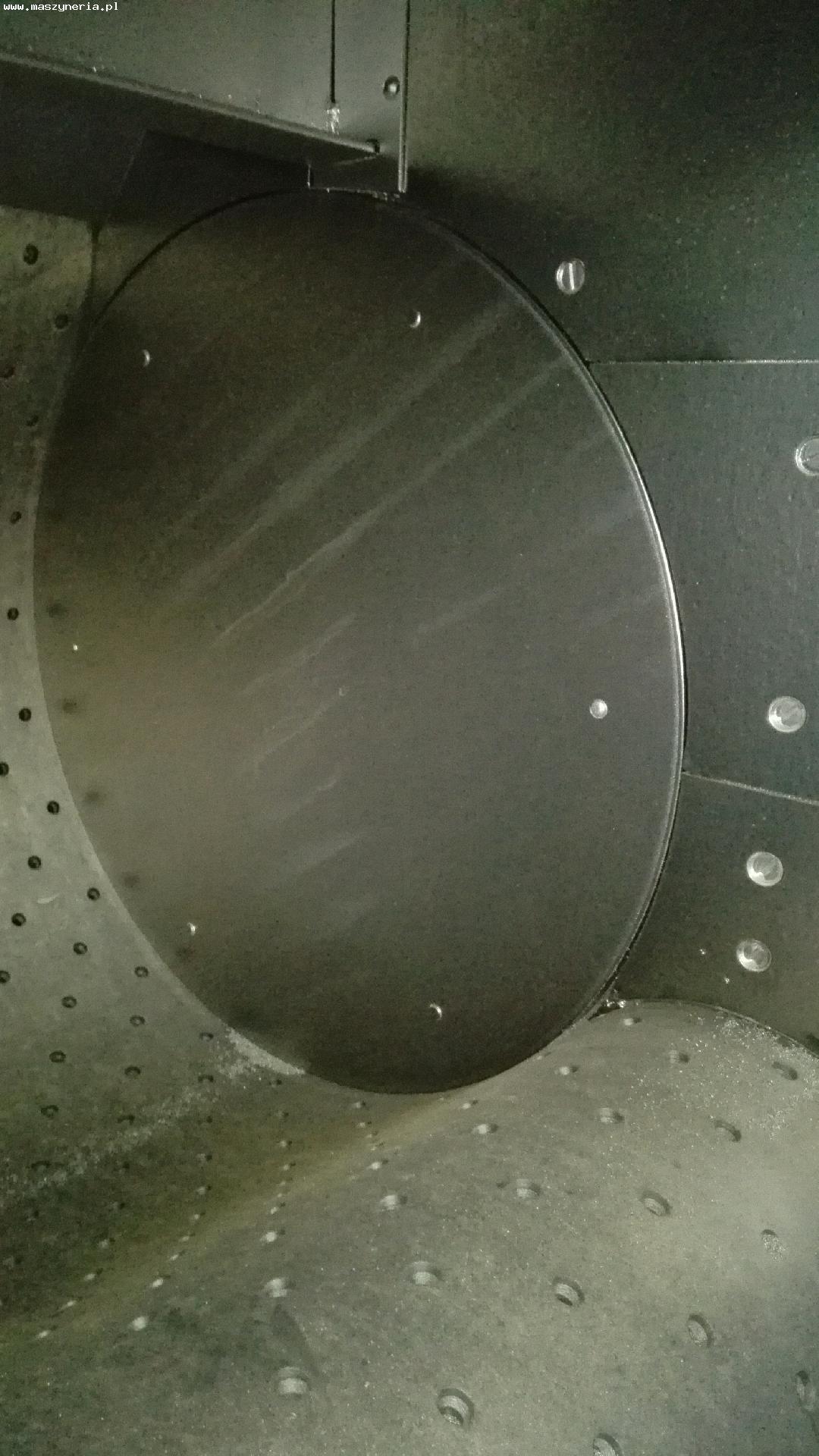

– impeller with drive,

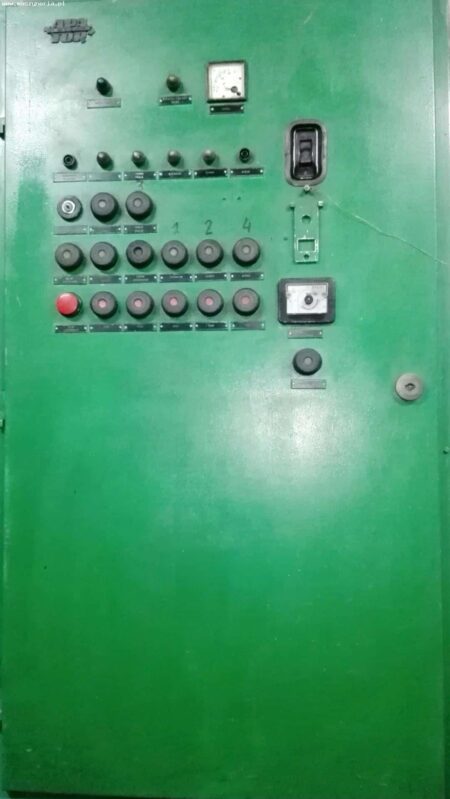

– electrical equipment,

– belt guide with auxiliary device,

– belt drive,

– machine chamber closure,

– separator,

– elevator.

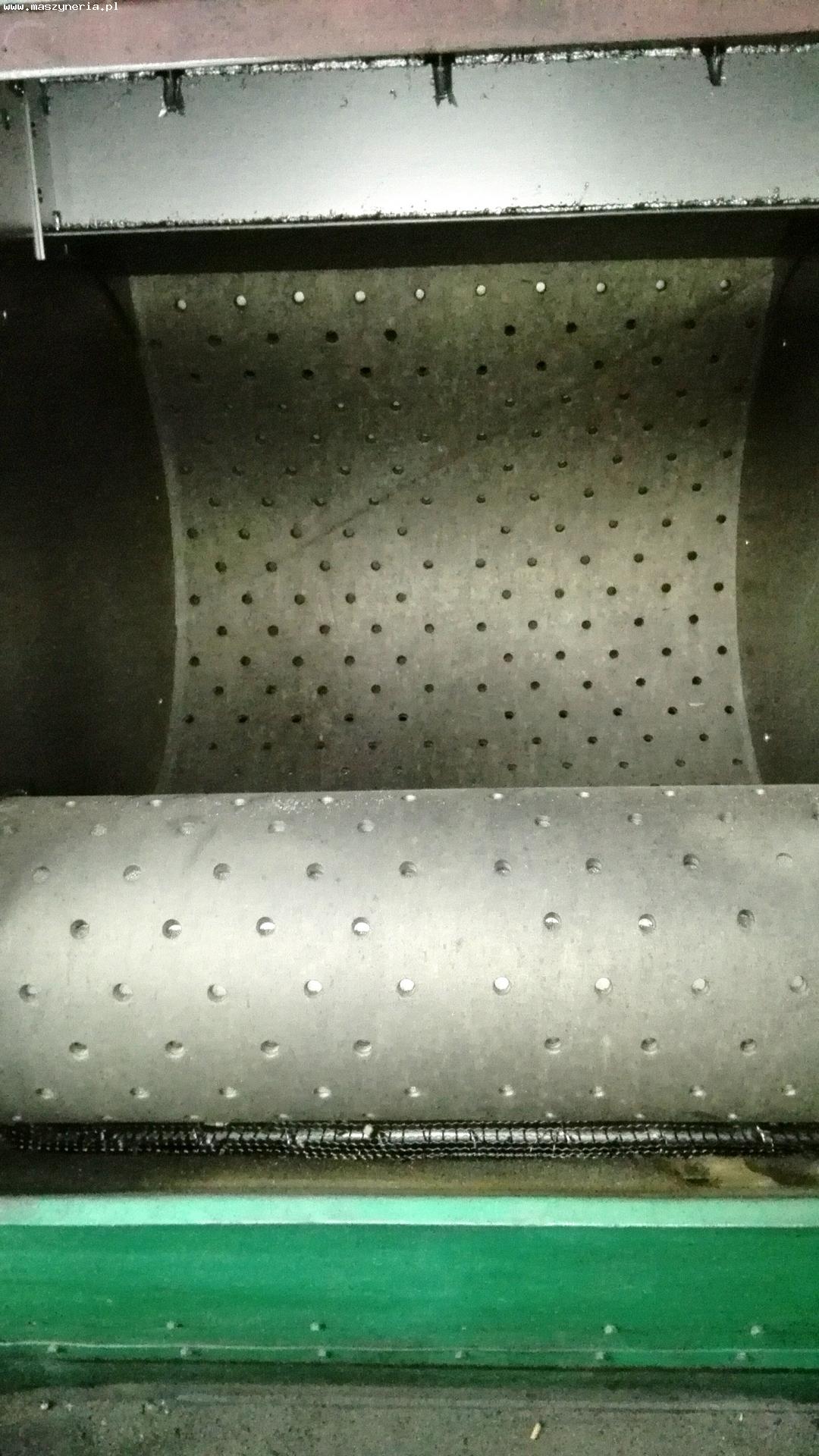

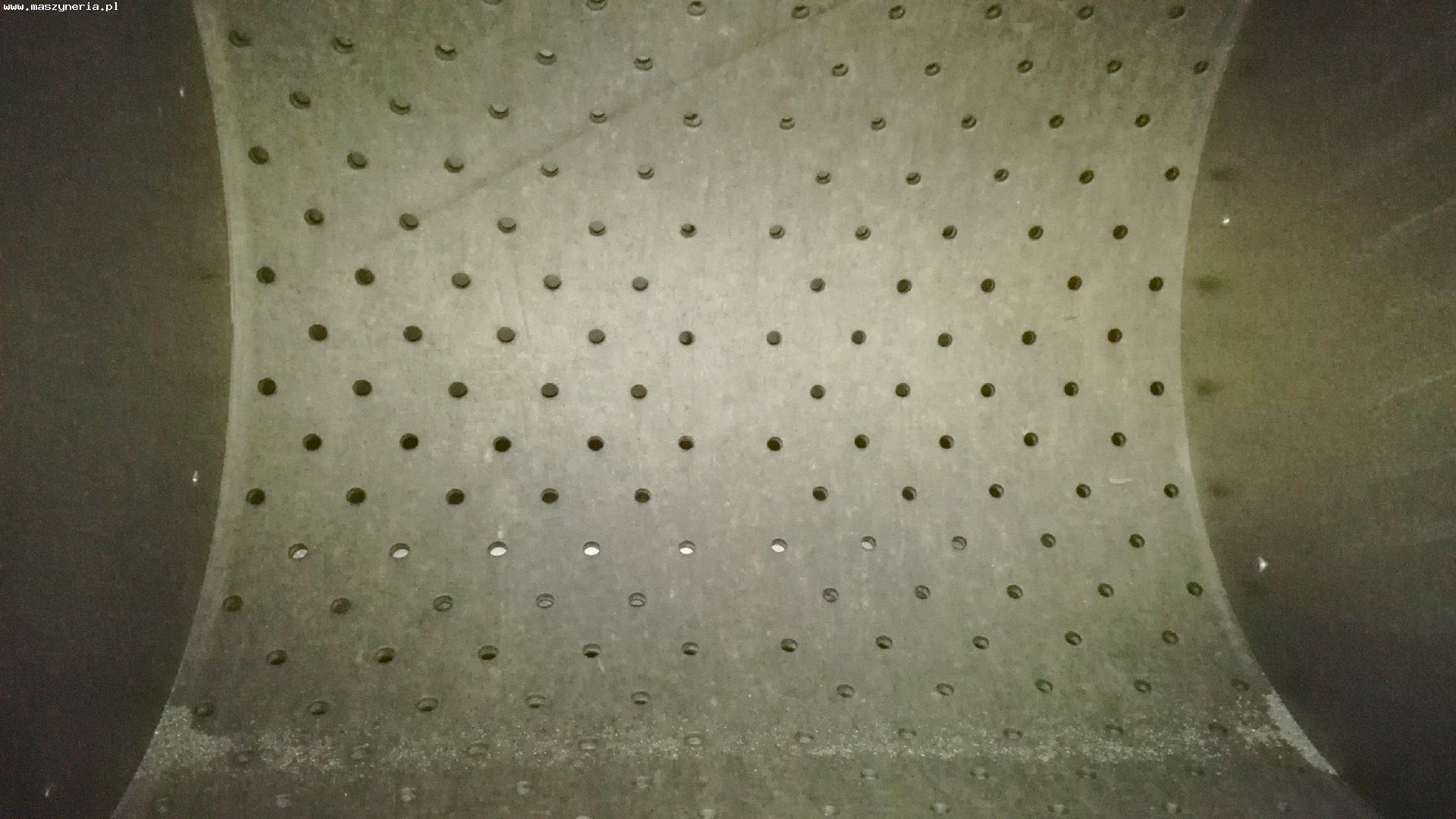

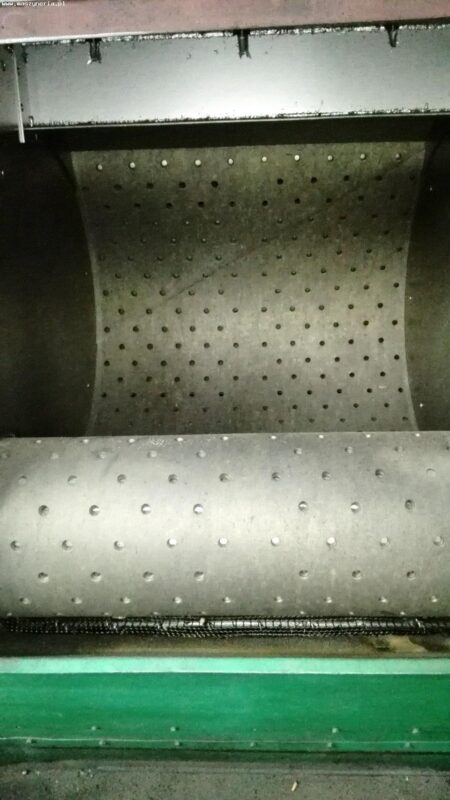

The belt guide with the auxiliary device is a set of three drums – driving, tensioning and endless belt drive. The guide wheels with protective shields located on the sides create a basin from the rubber belt. The belt is driven by an electric motor, belt-sprocket transmission, reducer and chain transmission that is located on the roof of working chamber. The rear of the working chamber is closed with a double door to facilitate the operation of the machine.

The machine is offered with a filtering chamber. It has also gone through a number of major renovations and improvements. In 2017, among others, the endless belt, curved and straight cartridges, side discs, guide wheels with rollers and holders, shock absorbers and the paddle wheel with guard were replaced. The 12 kW main power motor was also replaced at the end of 2018. The cost of all replaced parts is over 20000 PLN net. The total weight of the machine is 7500 kg.

Together with the OWT 400A machine, 2 tonnes of S390 steel shot are offered at a value of approximately EUR 2400.

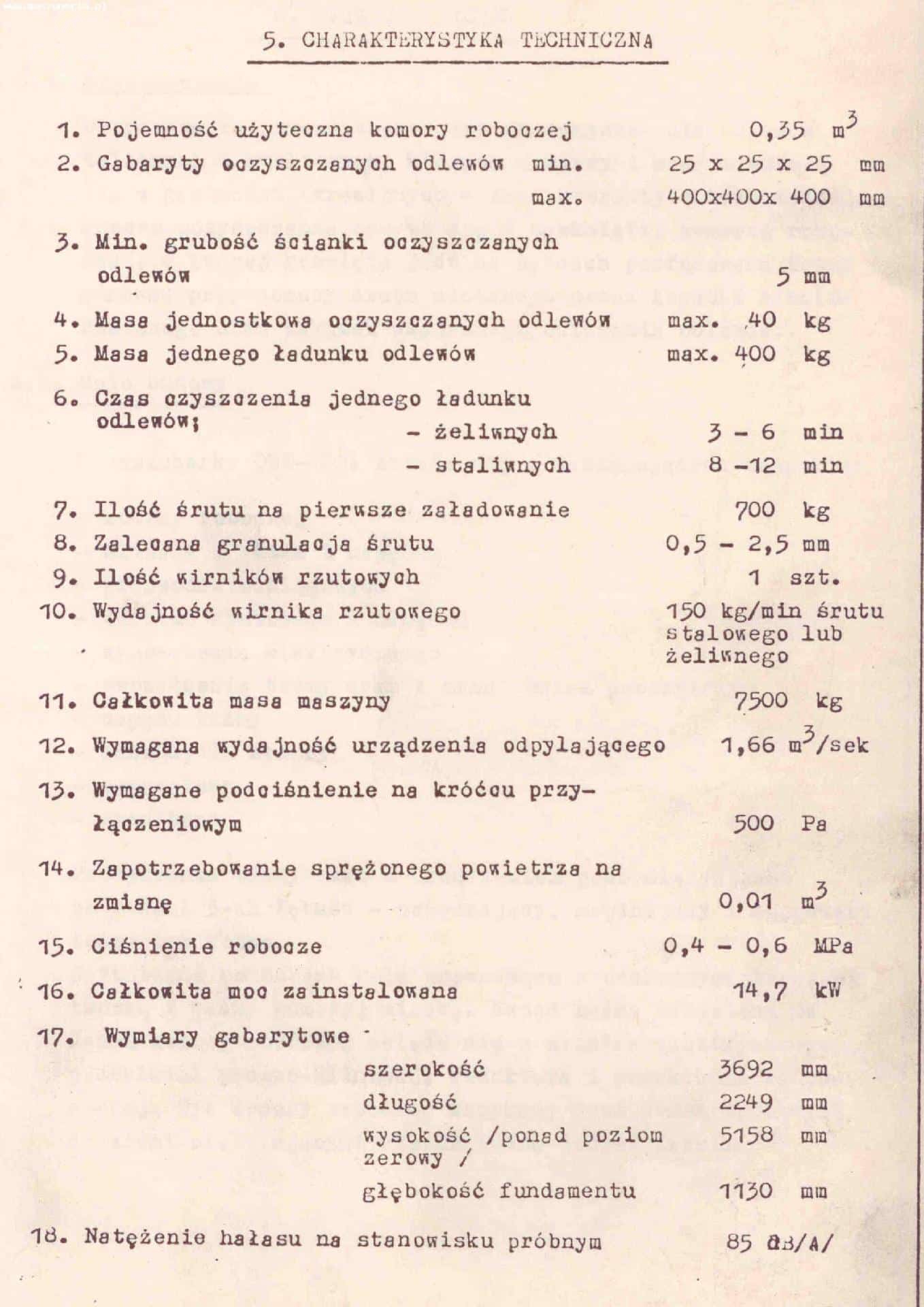

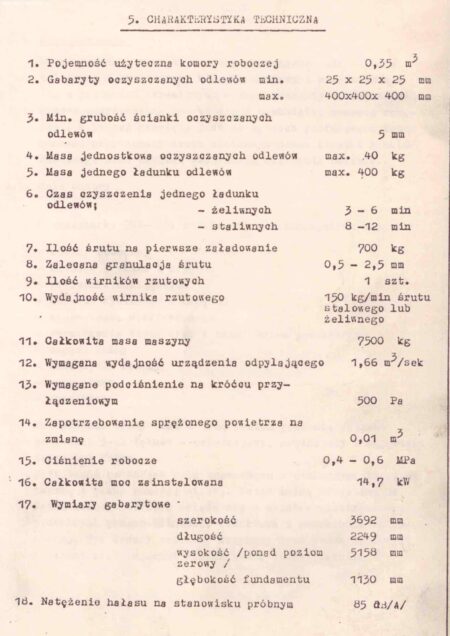

Technical specification of the fettling plant DOZAMET OWT 400A

- volume of the working chamber: 0,35 m3

- minimum weight of castings: 40 kg

- maximum weight of castings: 400 kg

- minimum casting dimensions (L x W x H): 25 x 25 x 25 mm

- maximum casting dimensions (L x W x H): 400 x 400 x 400 mm

- minimum wall thickness: 5 mm

- cleaning time per load (iron castings): 3-6 min

- cleaning time per load (steel castings): 8-12 min

- machine filtering chamber dimensions (L x W x H): 2100 x 1000 x 3100 mm

- quantity of blasting shot per first charge: 700 kg

- recommended grain size of shot: 0,5-2,5 mm

- number of impellers: 1 pcs.

- capacity of impeller: 150 kg/min of steel or cast iron shot

- required output of the dust collection device: 1.66 m3/sec.

- required underpressure at the connection port: 500 Pa

- compressed air demand per shift: 0,01 m3

- working pressure: 0.4-0.6 MPa

- installed power: 14.7 kW

- machine dimensions (L x W x H): 2249 x 3692 x 5158 mm

- total weight: 7500 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe