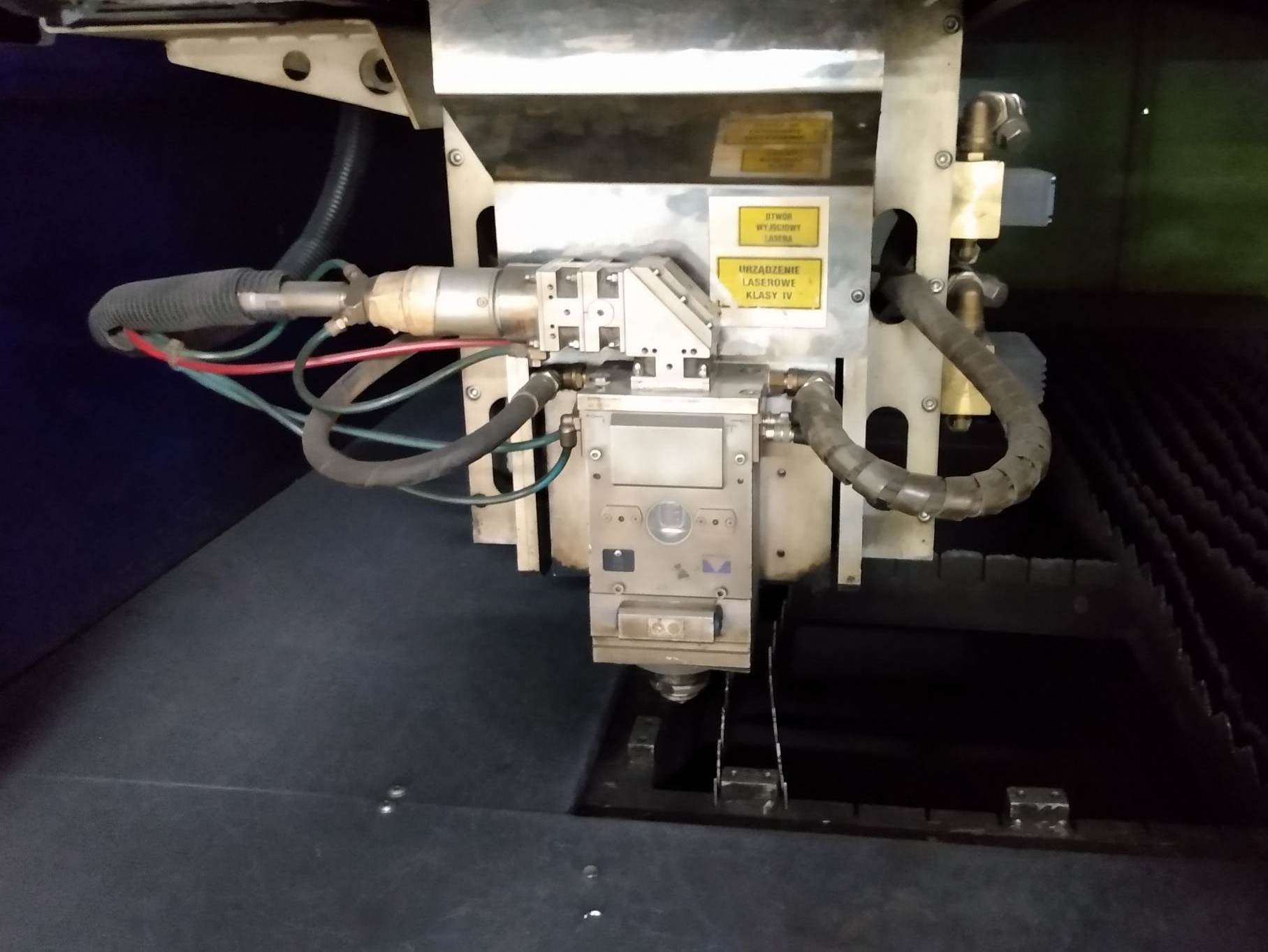

ECKERT DIAMENT FIBER laser cutting machine manufactured in 2012 in Poland, uses fiber-optic technology for machining sheets made of e.g. carbon steel, stainless steel and aluminium. The highest precision and quality of laser cutting is guaranteed thanks to the use of a reliable IPG YLS-1000 laser source, which delivers a 1 kW laser beam to the PRECITEC AK HP SSL cutting head. The portal-built laser with a fully enclosed cabin is equipped with, among others, a large work table with a length of 3000 mm and a width of 1500 mm with automatic pallet changer, a CNC ECS 872 controller and light curtains.

Technical data of the ECKERT DIAMENT FIBER laser cutting machine

- laser power: 1 kW

- work table surface (L x W): 3000 x 1500 mm

- maximum workpiece thickness (carbon steel): 10 mm

- maximum workpiece thickness (stainless steel): 5 mm

- maximum workpiece thickness (aluminium): 4 mm

- filter-fan power: 5.5 kW

- number of filter cartridges: 4

- power supply of DIAMENT FIBER machine: 400 V

Equipment of the laser cutting machine

- CNC control: ECS 872

- laser resonator: IPG YLS-1000

- automatic pallet changer

- light curtains

- cutting head: PRECITEC AK HP SSL

- radiator: RIEDEL PC 41.02-KE-S1

- filter-fan with extraction system: PFC-4

Since its purchase, the fiber laser has been operated very sparingly and serviced according to the manufacturer’s recommendations. The laser resonator was operated for approximately 3-4 hours in one day.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe