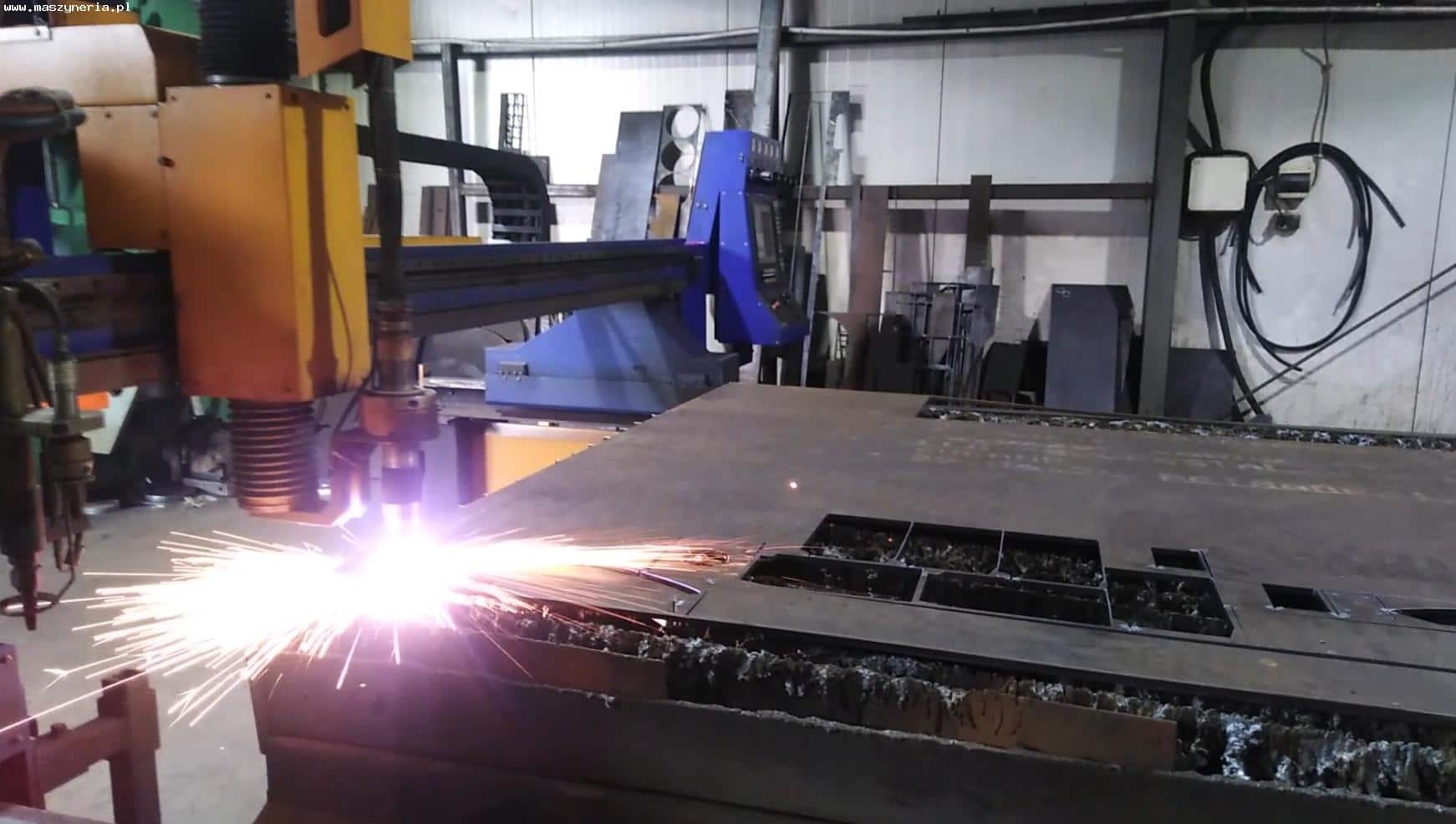

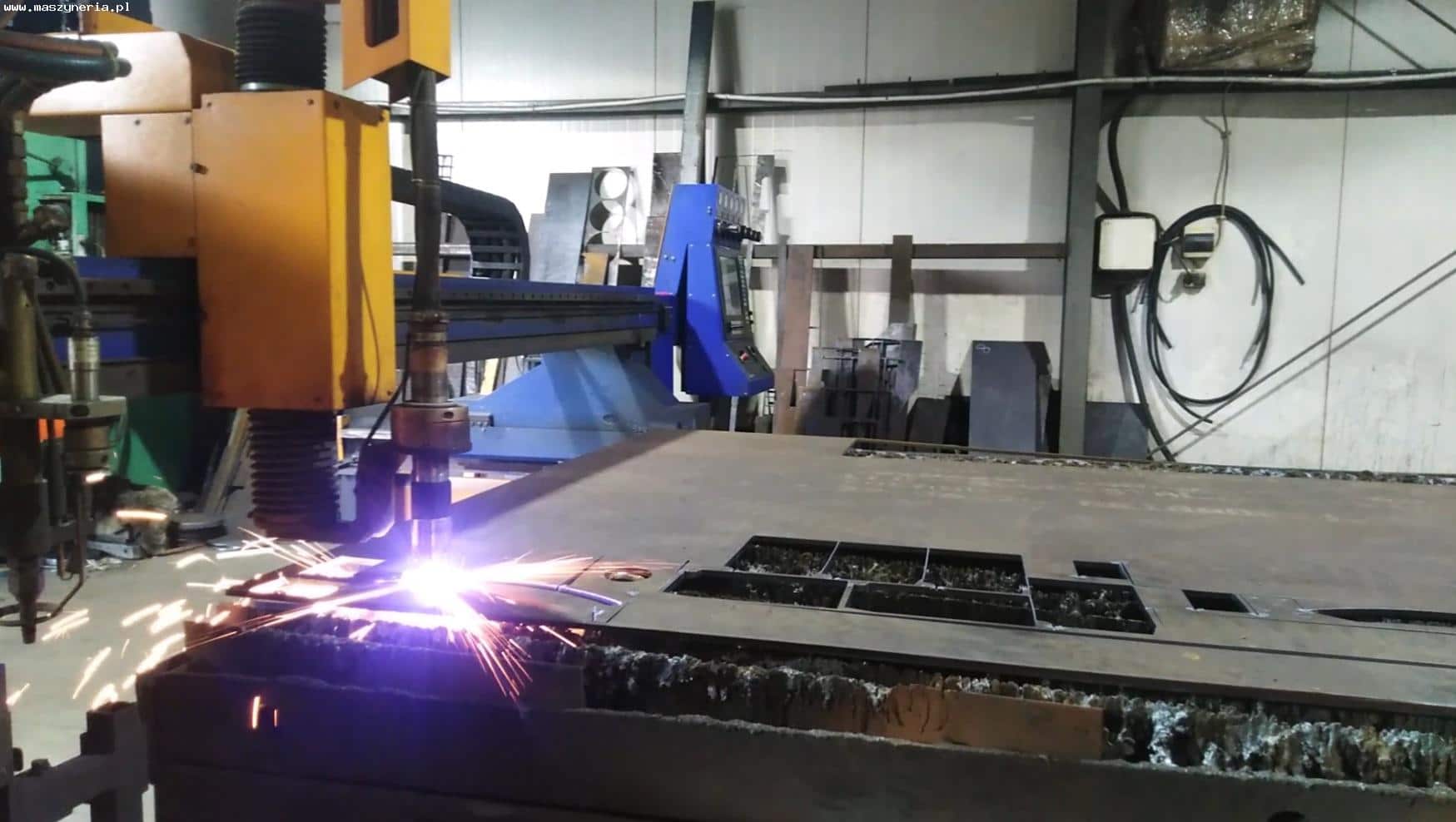

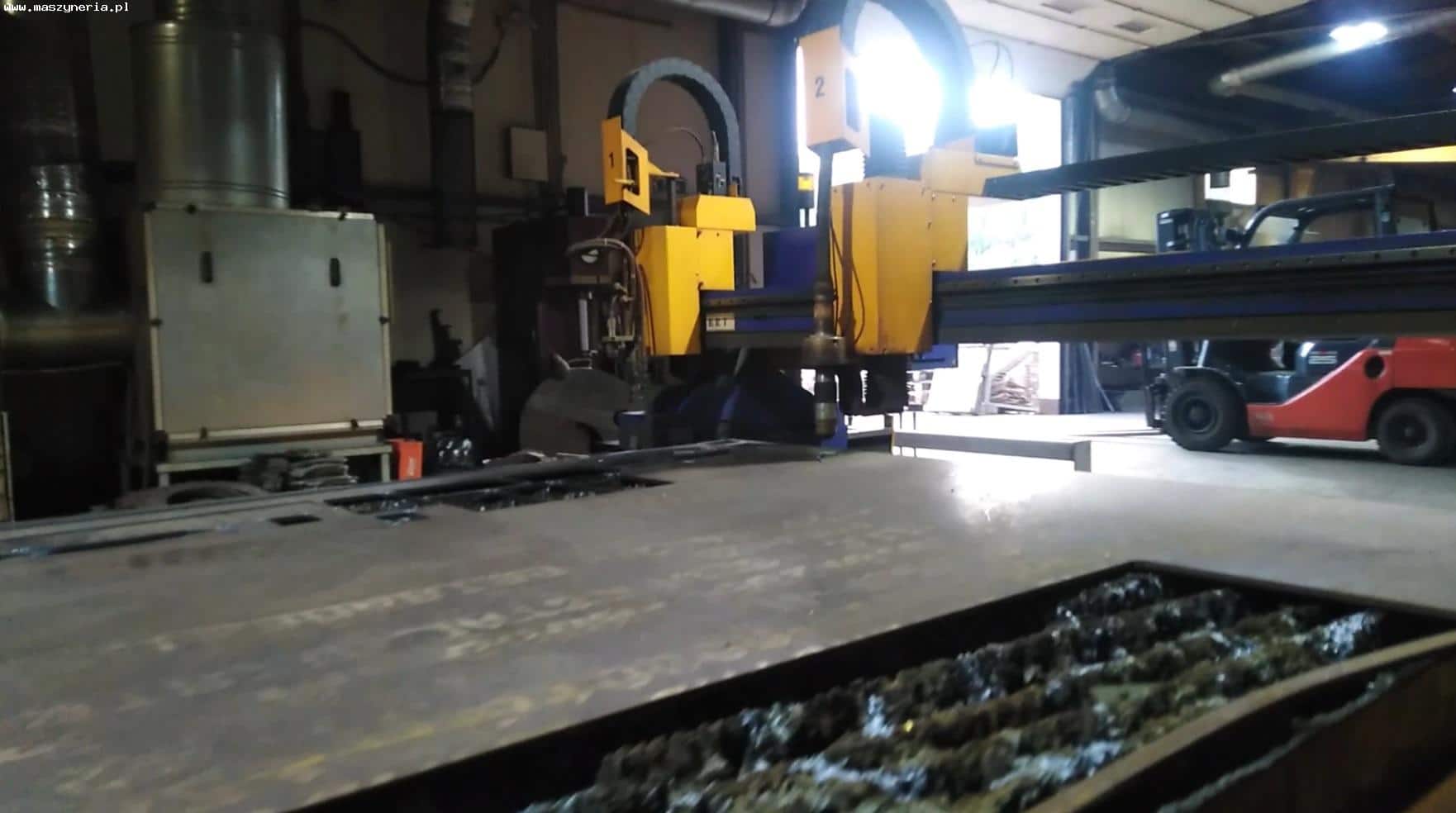

The ECKERT JANTAR 2 plasma cutter was built in 2010. The plasma cutter cuts a sheet of metal with dimensions (L x W) 2000 x 3000 mm. The machine is equipped with: CNC control ECS 872 and an efficient plasma aggregate HYPERTHERM HPR260. The cutting speed of the machine reaches 25,000 mm/min.

Technical data of the plasma cutter ECKERT JANTAR 2

– number of man-hours: 5026 h

– drive: X axis: double-sided – AC servo, Y axis – AC servo, Z axis – servoAC HD3000 bottom bracket

– cutting width (L x W): 2000 x 3000 mm

– cutting speed: 50-25000 mm/min. (depends on the cutting tool)

– travel speed: 25,000 mm/min.

– cutting thickness with 1 oxygen torch: 100 mm

– CNC positioning accuracy: 0.0005 mm

– required table height: 700 mm

Equipment of the plasma cutter ECKERT JANTAR 2

– CNC control: ECS 872

– plasma aggregate: HYPERTHERM HPR260, manual console

– manual gas console with solenoid valves

– a set of high efficiency reducers for gas cutting

– HD 3000 plasma torch support with distance control by measuring the intensity of the plasma arc

– oxygen burner support with a capacitive distance sensor, HARRIS oxygen burner and automatic igniter

– laser position indicator of the burner

– air preparation unit (dryer, oil separator, reducer)

– controller cooling and heating system

– elements of the extraction system

– high-efficiency exhaust fan W 7700

– CNCcut IBE computer program, with nesting

– sectional extraction table: 2000 x 3000 mm

– brackets for mounting the upper guiding of the extraction system

– brackets for top mounting of the fan on the external wall

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe