ECKERT JANTAR 2 plasma cutting machine was manufactured in 2009 in Poland. The machine is used to cut predesigned shapes in sheet metal made of black steel, stainless steel or aluminium. The parts are cut in workpieces with a maximum width of 2000 mm, a maximum length of 6000 mm and a thickness between 0.5 mm and 80 mm, using KJELLBERG PerCut 451 plasma torches, guaranteeing the best quality and a cutting speed of up to 20 m/min.

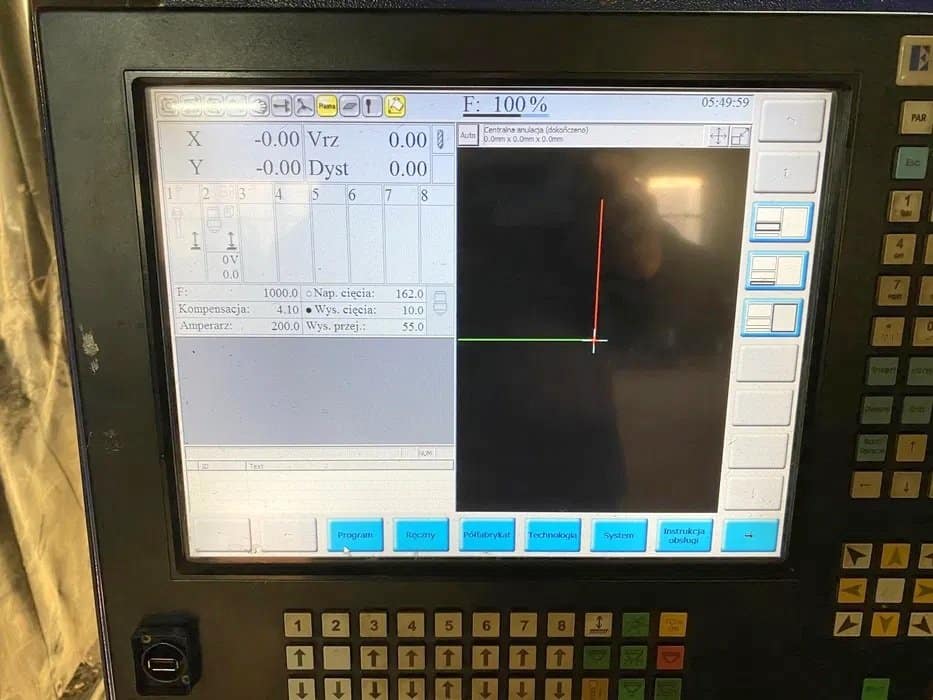

The open design gives access to the working table from each side of the machine, allowing easy placement of the workpiece by the operator. Any vibration and dust generated during machining is eliminated by a portal made of top quality welded steel equipped with an extraction table. The plasma cutting machine is also equipped with a KJELLBERG HIFocus 360i plasma source and a CNC control ECS 872 with control panel, for full control of the machine’s operation.

Specifications of ECKERT JANTAR 2 plasma cutting machine

- cut materials: stainless steel, black steel, aluminium

- minimum thickness of workpiece: 0.5 mm

- maximum thickness of workpiece: 80 mm

- maximum cutting speed: 20 m/min

- working table dimensions (L x W): 6000 x 2000 mm

- working table height: 740 mm

- positioning speed: 25000 mm/min

Equipment of the plasma cutting machine

- CNC control: ECS 872

- plasma source: KJELLBERG HIFocus 360i

- plasma torch of the machine: KJELLBERG PerCut 451 (2 units)

- extraction table

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe