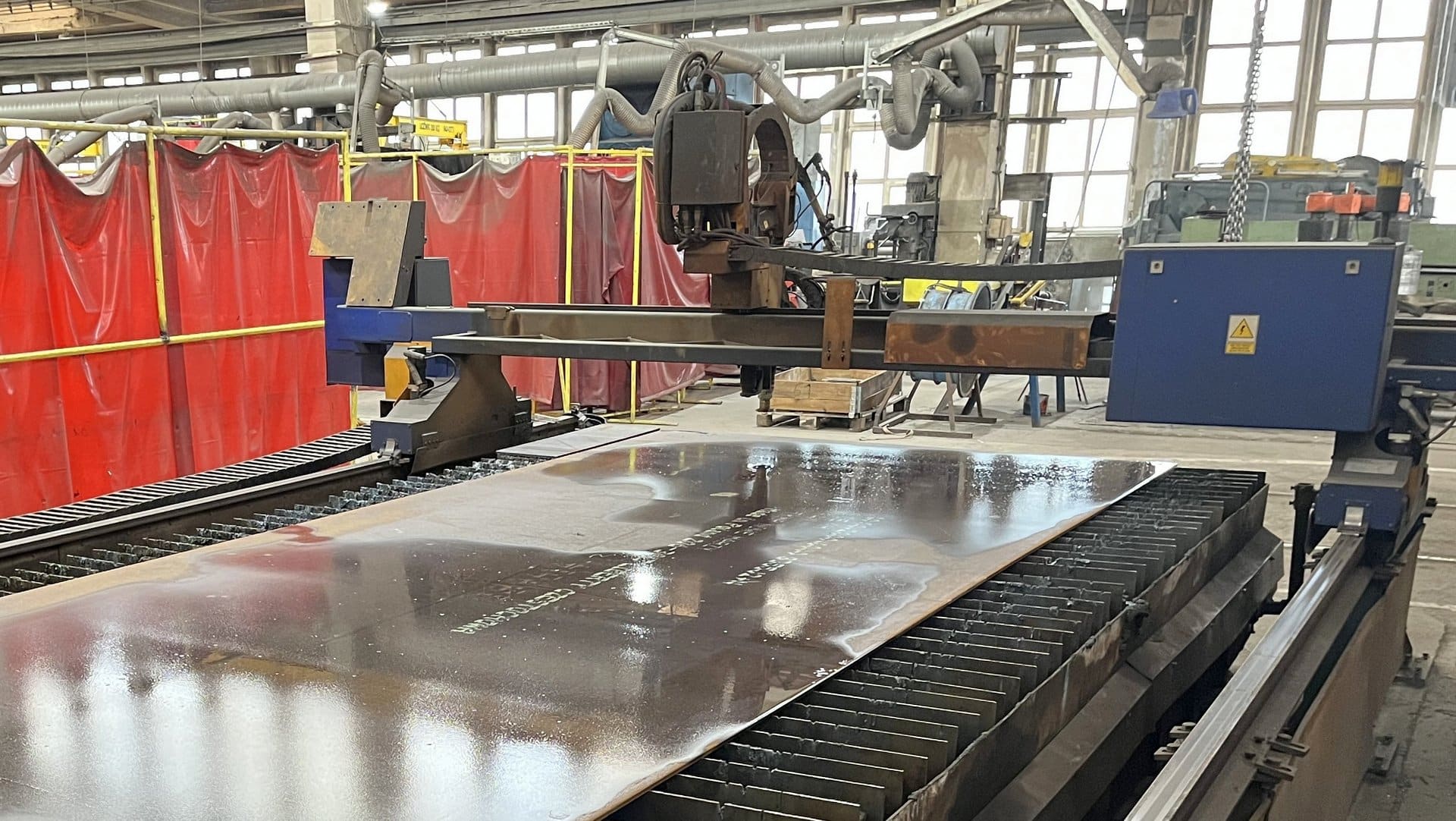

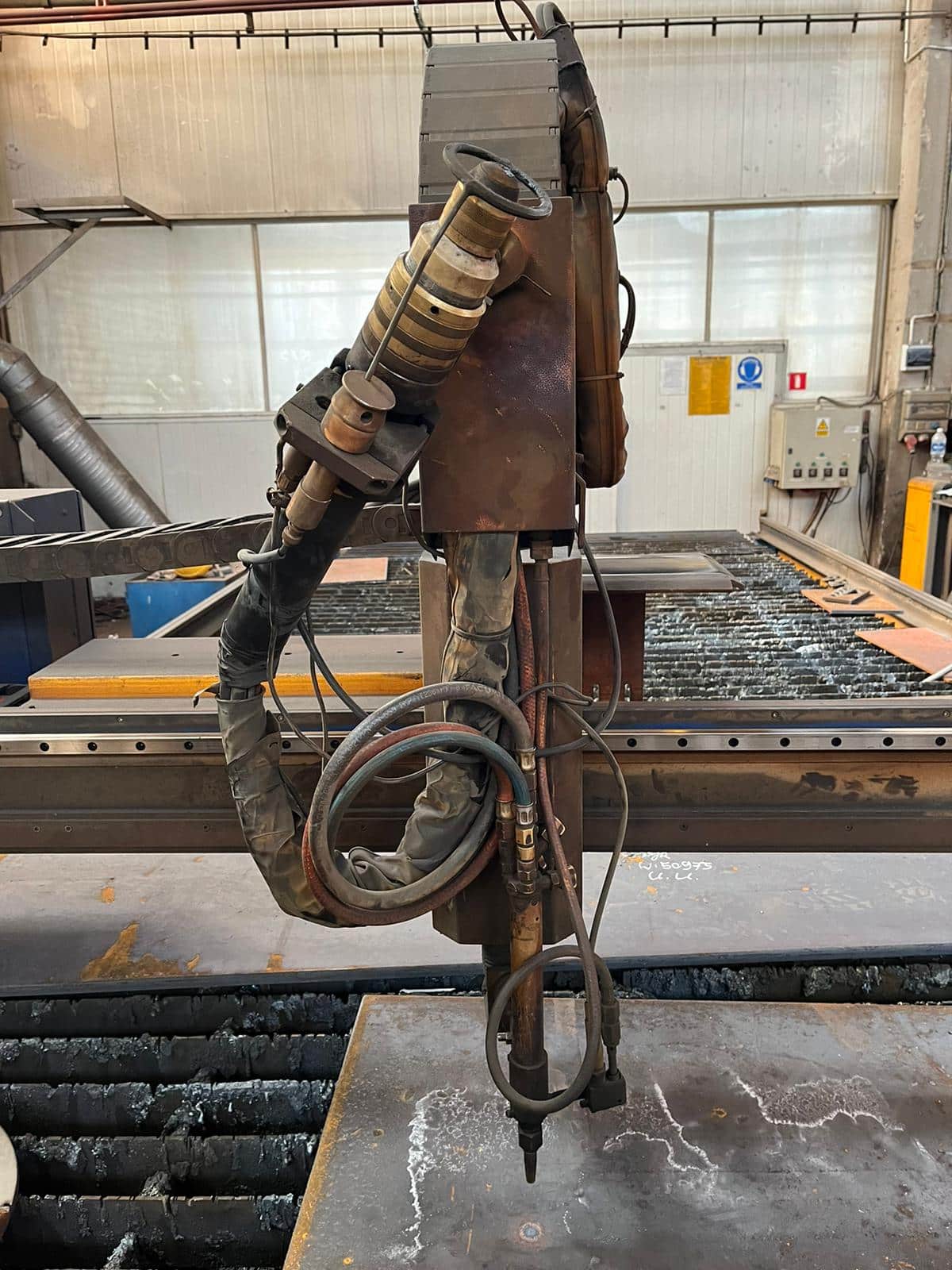

ECKERT JANTAR 2 plasma-gas cutting machine was manufactured in 2008 in Poland. The machine is used for shape cutting in workpieces having a maximum thickness of 40 mm (plasma cutting) or 100 mm (oxygen cutting), on a working table with a length of 6000 mm and a width of 2500 mm. Made from high-quality welded steel, the portal of the plasma cutting machine provides great rigidity and stability during heavy-duty machining.

The plasma cutting machine is equipped with a highly reliable KJELLBERG HIFocus 280i plasma source and an extraction table, effectively eliminating dust generated during the cutting process. The control panel with the convenient and intuitive ECS 859 numerical control, allows many different cutting programmes to be programmed in ESSI format.

Technical parameters of ECKERT JANTAR 2 plasma cutting machine

- working table size (L x W): 6000 x 2500 mm

- cutting materials: stainless steel, carbon steel, acid resistant steel, black steel, aluminium

- maximum workpiece thickness (plasma cutting): 40 mm

- maximum workpiece thickness (oxygen cutting): 100 mm

- traverse speed: 10-6000 mm/min

- positioning speed: 25000 mm/min

- support working stroke: 125 mm

- programming format: ESSI

- working table height of JANTAR 2 machine: 760 mm

Equipment of the plasma cutting machine

- CNC controller: ECS 859

- plasma source: KJELLBERG HIFocus 280i

- extraction table

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe