ECKERT JANTAR plasma cutting machine was manufactured in 2017 in Poland. Characterised by a robust and stable construction, the machine is designed for cutting shapes in workpieces made of mild steel, stainless steel or aluminium. For precise machining of sheets having a maximum thickness of 38 mm (mild steel) or 25 mm (stainless steel and aluminium), it uses a plasma torch equipped with an HD3000 support with distance adjustment by measuring the plasma arc voltage.

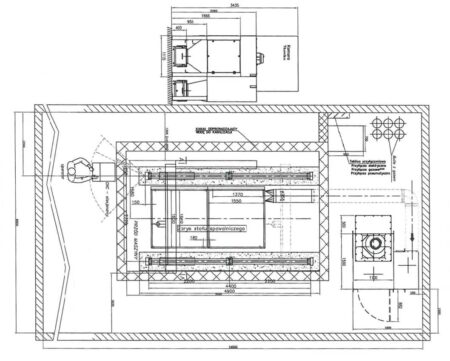

The process of cutting workpieces is carried out on a working area measuring 2000 mm in length and 3000 mm in width, equipped with an extraction table eliminating the impurities generated during processing. The plasma cutting machine is offered with a wide range of equipment, including: modern CNC controller ECS 872 for full control over the operation of the machine, and a HYPERTHERM HPR130XD plasma source.

Technical data of the ECKERT JANTAR plasma cutting machine

- cutting length: 2000 mm

- minimum cutting width: 1500 mm

- maximum cutting width: 3000 mm

- maximum workpiece thickness (mild steel): 38 mm

- maximum workpiece thickness (stainless steel): 25 mm

- maximum workpiece thickness (aluminium): 25 mm

- minimum travel speed: 10 mm/min

- maximum travel speed: 10000 mm/min

- travel length: 4000 mm

- length of travel extension: 2000 mm

- accuracy of sheet distance adjustment: 0.1 mm

- working stroke of support: 125 mm

- working table height of JANTAR machine: 760 mm

Equipment of the plasma cutting machine

- CNC control: ECS 872

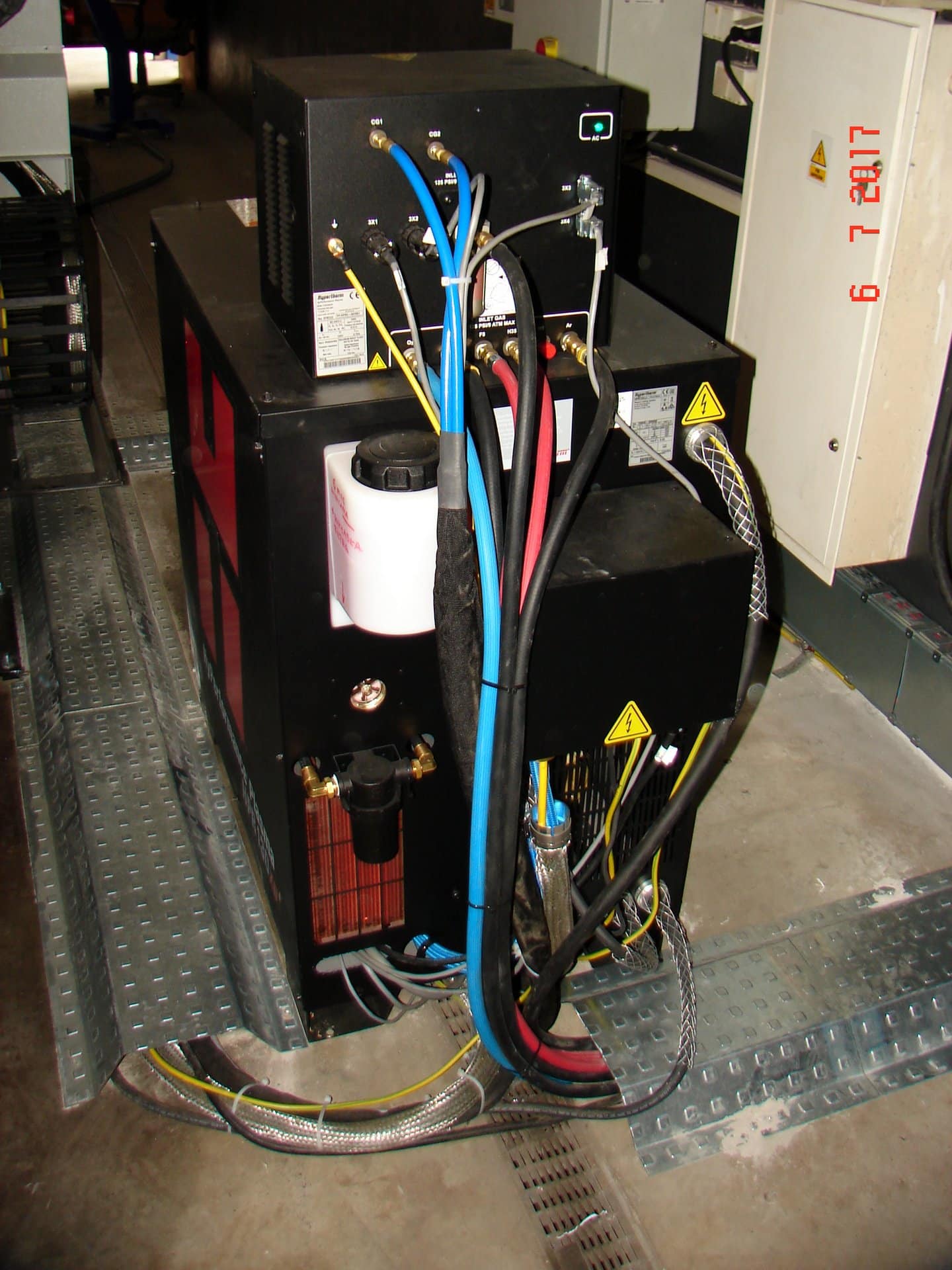

- plasma source: HYPERTHERM HPR130XD

- filtration unit: DONALDSON DFPRO 4

- extraction table

- AC servomotor

- plasma torch

- plasma torch support HD3000 with distance adjustment by measuring the plasma arc voltage

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe