ECKERT JANTAR plasma cutting machine manufactured in Poland in 2015, is designed for shape cutting in details made of among others stainless steel, carbon steel or aluminium. The machine made of the highest quality steel, ensures high stability and effective dampening of vibrations generated during machining and, thanks to its open design, also allows for easy loading and unloading of metal sheets onto the work table equipped with exhaust extraction.

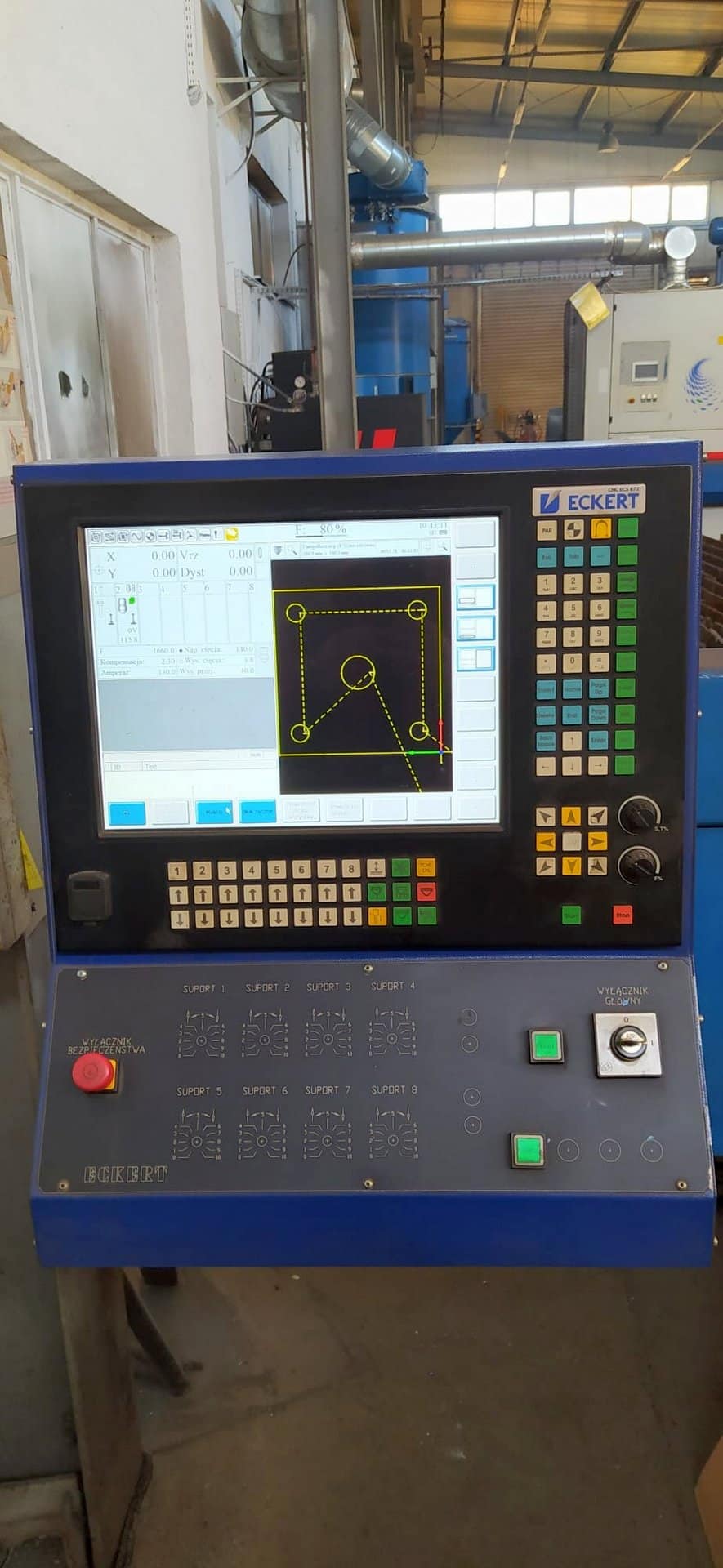

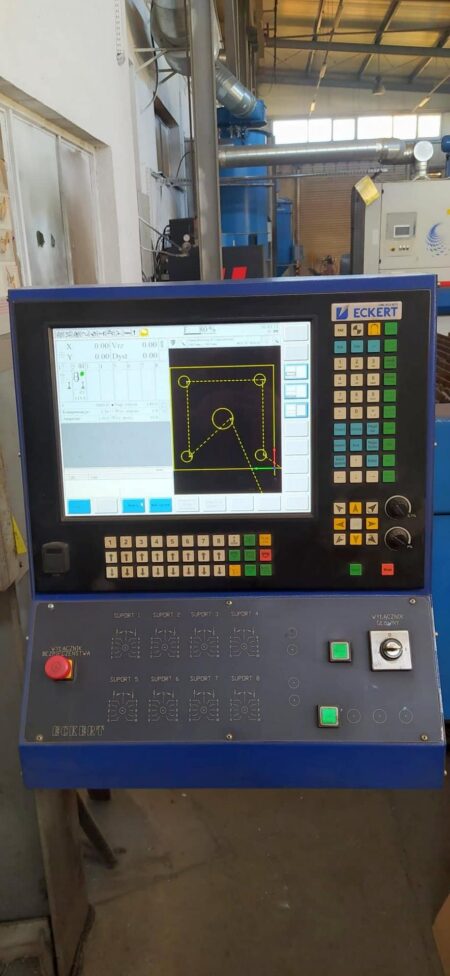

The plasma cutting machine uses a reliable HYPERTHERM HyPerformance HPR260XD plasma source with a power of 260 A to cut workpieces with maximum dimensions (L x W) of 6000 x 2000 mm and a thickness of up to 50 mm. An additional oxygen torch also allows processing of sheet metal with a maximum thickness of 150 mm. The plasma-gas cutting machine is numerically controlled via arm-mounted operator panel with ECS 872 control installed, offering the use of all available machine functions.

Technical parameters of ECKERT JANTAR plasma-gas cutting machine

- cut materials: mild steel, carbon steel, stainless steel, aluminium

- work table surface (L x W): 6000 x 2000 mm

- maximum cutting thickness (carbon steel): 35 mm

- maximum cutting thickness (stainless steel): 50 mm

- maximum cutting thickness (aluminium): 50 mm

- maximum cutting thickness (oxygen torch): 150 mm

- height of the JANTAR machine work table: 740 mm

- travel speed: 10-10000 mm/min

- positioning speed: 25000 mm/min

- adjustment accuracy of distance from sheet metal: 0.1 mm

- plasma source power: 260 A

- rated current: 12 A

- power supply: 230 V

Equipment of the plasma-gas cutting machine

- CNC controller: ECS 872

- plasma source: HYPERTHERM HyPerformance HPR260XD

- extraction table

- plasma torch

- oxygen torch

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe