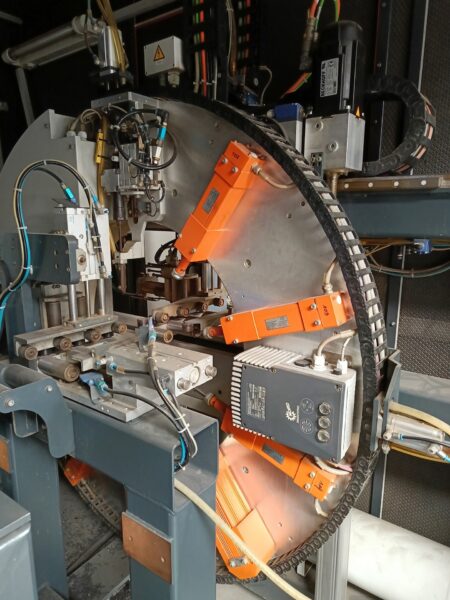

ELUMATEC SBZ 618 machining center was built in 2014 in Germany by Elumatec AG. The machine enables fully automatic machining of profiles made of steel, aluminium and PVC. Its excellent machining parameters and high precision make it an excellent choice for businesses associated with e.g. window or door manufacturing. The profiles are cut by a reliable saw with a 550 mm diameter and with an angle adjustment range of -22.5° to +22.5°. The machining unit is also equipped with a reliable spindle for milling and hole-making. The ELUMATEC profile machining center is offered with a wide range of equipment, including a magazine capable of accommodating 10 profiles as well as a barcode scanner and label printer. The total weight of the machine is approximately 5500 kg.

Technical specifications of the ELUMATEC SBZ 618 profile drilling and cutting center

- maximum workpiece length: 4000 mm

- minimum workpiece length: 400 mm

- X axis positioning speed: 200 m/min

- maximum spindle rotational speed: 20000 rpm

- saw blade diameter: 550 mm

- saw blade deflection: -22,5°/+22,5°

- cutting station

- magazine with space for 10 profiles

- barcode scanner

- label printer

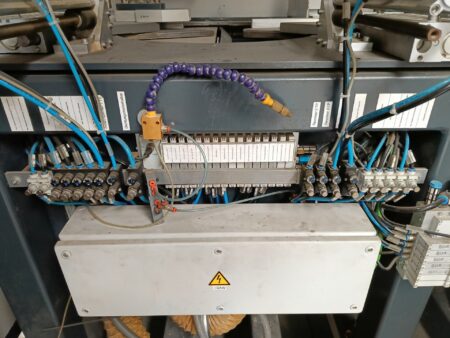

- compressed air pressure: 6-8 bar

- saw motor power: 4 kW

- drilling unit power: 1.2 kW

- installed power: 29 kW

- power supply: 3x 400 V; 50 Hz

- total weight of ELUMATEC SBZ 618 machine: approx. 5500 kg

– maximum rotational speed: 4000 rpm

– maximum base cutter diameter: 150 mm

– minimum number of teeth: 6, mitre cut with chip breaker

– 4-position automatic tool changer

– tool holder: HSK-F63

– clamping hole diameter: 30 mm

– balance quality (whole tool): 2,5 G

– maximum total weight: 6 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe