ENGEL ES 200/75 HL-V injection moulding machine was built in Austria in 2000. The highly reliable and robust machine is designed for processing plastics by injection moulding. The high-end components installed on the ENGEL ES 200/75 HL V injection moulding machine guarantee a significant increase in work efficiency and productivity.

The machine operating with a force of 75 tonnes works with injection moulds of a minimum height of 200 mm, which are placed on 660 x 560 mm platens. All process parameters are programmed and controlled on the convenient and intuitive ENGEL CNC control, located on the body of the plastics processing machine. The total weight of the machine is 4700 kg.

Technical specifications of the ENGEL ES 200/75 HL-V injection moulding machine

- CNC control: ENGEL

- clamping force: 75 t

- injection volume: 135 cm3

- injection pressure: 1065 bar

- injection speed: 117 mm/s

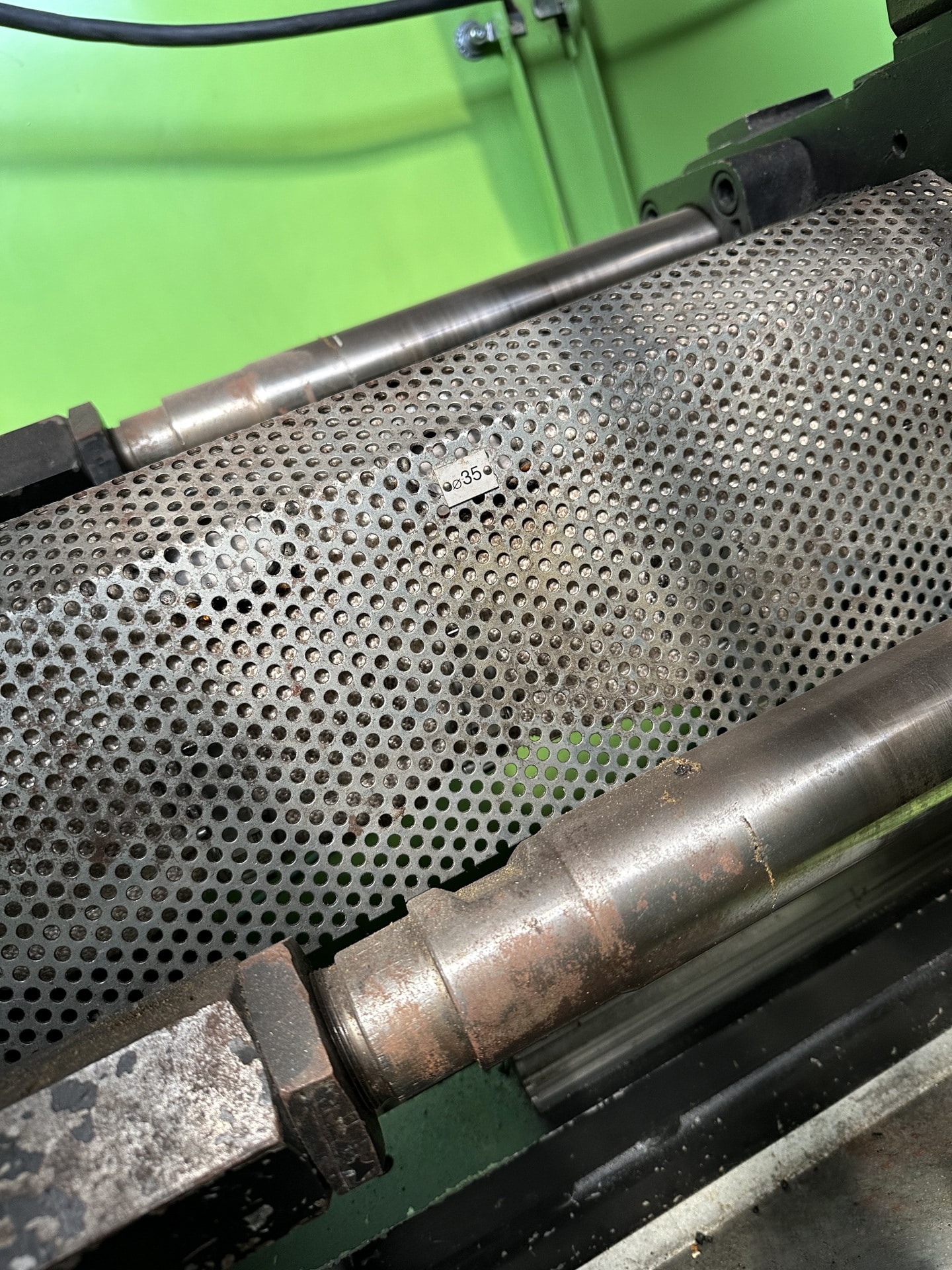

- screw diameter: 35 mm

- minimum screw speed: 20 rpm

- maximum screw speed: 480 rpm

- minimum mould height: 200 mm

- maximum mould opening stroke: 650 mm

- mould mounting platen size (L x W): 660 x 560 mm

- mould mounting hole dimension (fixed plate): 125 mm

- mould mounting hole dimension (movable plate): 125 mm

- dispensing path: 140 mm

- ejector stroke: 100 mm

- oil tank capacity: 140 l

- pump motor power: 15 kW

- cylinder heating power: 6.8 kW

- dimensions (L x W x H): 3800 x 1300 x 2000 mm

- weight of machine ES 200/75 HL-V: 4700 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe