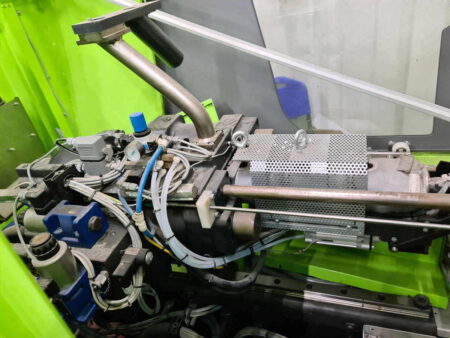

ENGEL INSERT 60H/30 SHUTTLE injection moulding machine was manufactured in 2016 in Austria. A specialised machine with a small footprint, is used for, among others, the overmoulding of inserts and the joining of various materials such as glass, metal and electronics. Thanks to the electric control of the injection unit and the ‘pressure locking’ system for the injection cylinders, the injection moulding machine guarantees high repeatability and excellent quality of inserts.

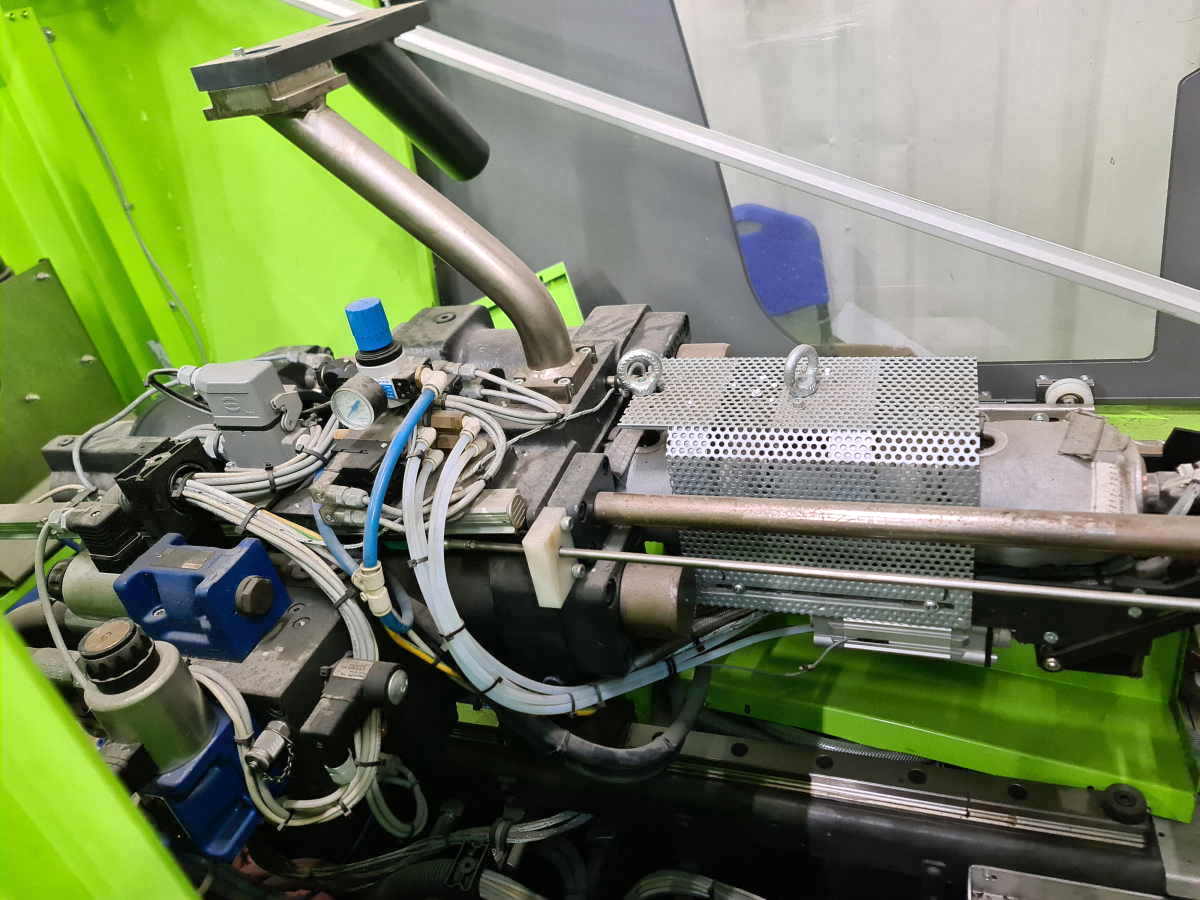

The ENGEL INSERT 30 injection moulding machine allows you to set the speed and clamping force to prevent damage to the mould. Once both mould halves are closed and a high closing force is generated, the injection unit pushes the nozzle against the injection sleeve of the mould and produces an adjustable clamping force. At the end of the cycle, a very powerful screw with a diameter of 18 mm injects the melt under high pressure into the mould cavity. To prevent the molten material from backing up into the screw coils, the screw is equipped with a mechanical valve lock.

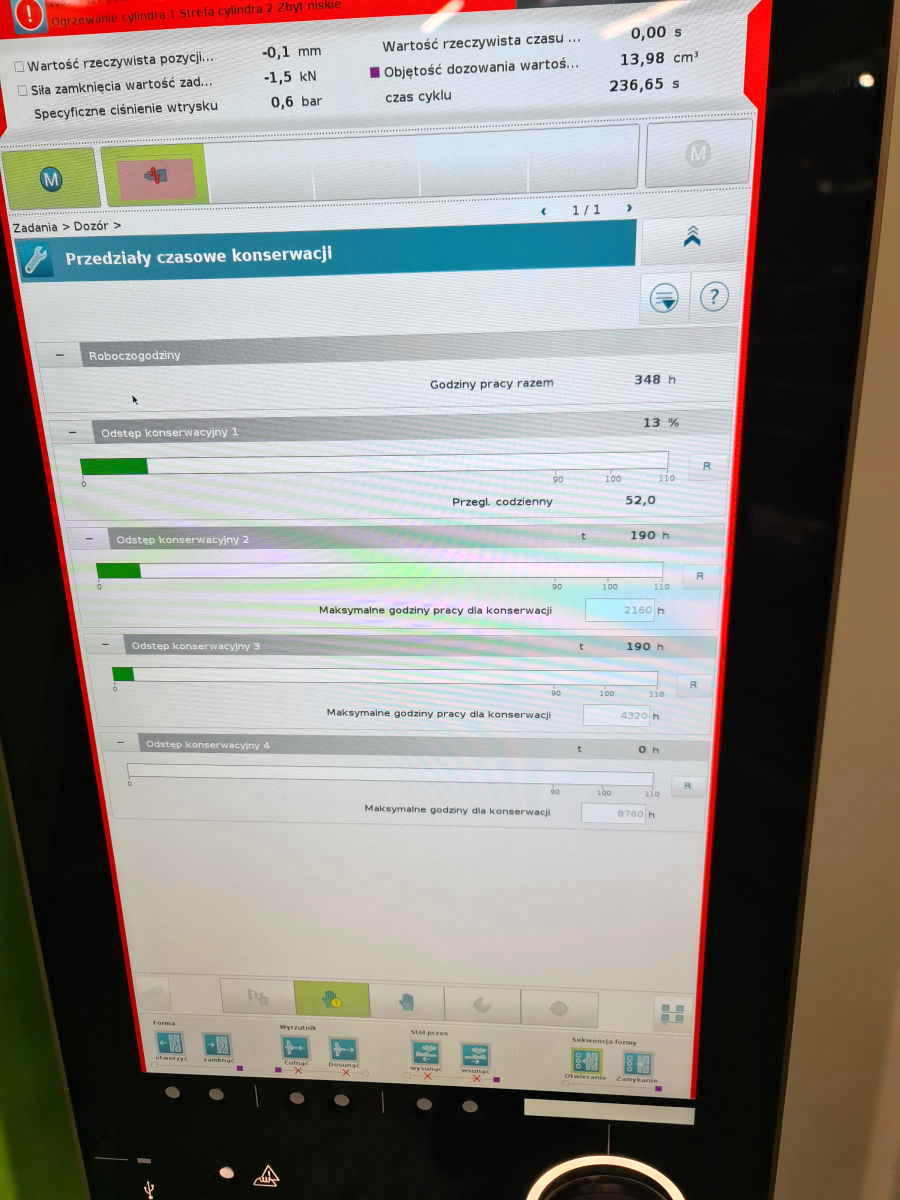

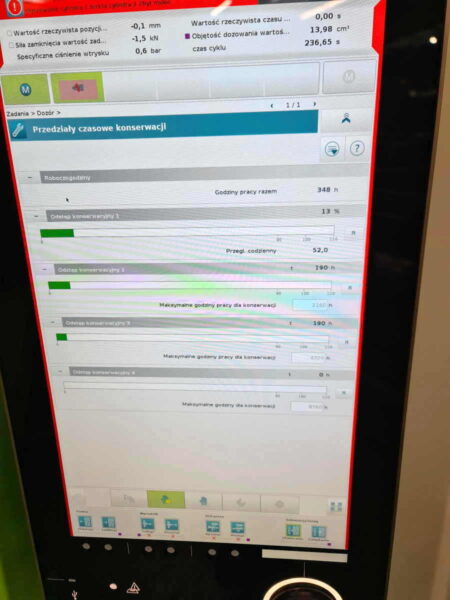

The machine operating with a maximum clamping force of 30 tonnes is equipped with a large sliding table with workstations on the left and right sides of the injection station, significantly facilitating mould handling. The machine’s extensive equipment also includes a PIOVAN S50 plastic feeder with integrated blower, an ENGEL flomo mould temperature controller and a state-of-the-art ENGEL CC300 CNC control with touchscreen. The vertical injection moulding machine has only worked 348 hours.

Technical specifications of the ENGEL INSERT 60H/30 SHUTTLE plastic injection moulding machine

- man-hours: 348 h

- maximum clamping force: 30 t (300 kN)

- injection volume: 25 cm3

- injection capacity: 66 cm3/s

- increased injection capacity: 49 cm3/s

- injection pressure: 1815 bar

- increased injection pressure: 2204 bar

- mould opening stroke: 308 mm

- screw diameter: 18 mm

- maximum screw speed: 450 rpm

- injection nozzle stroke: 530 mm

- injection nozzle clamping force: 28,3 kN

- nozzle bore: 3 mm

- nozzle radius: 35 mm

- ejector stroke: 105 mm

- ejector force: 20.1 kN

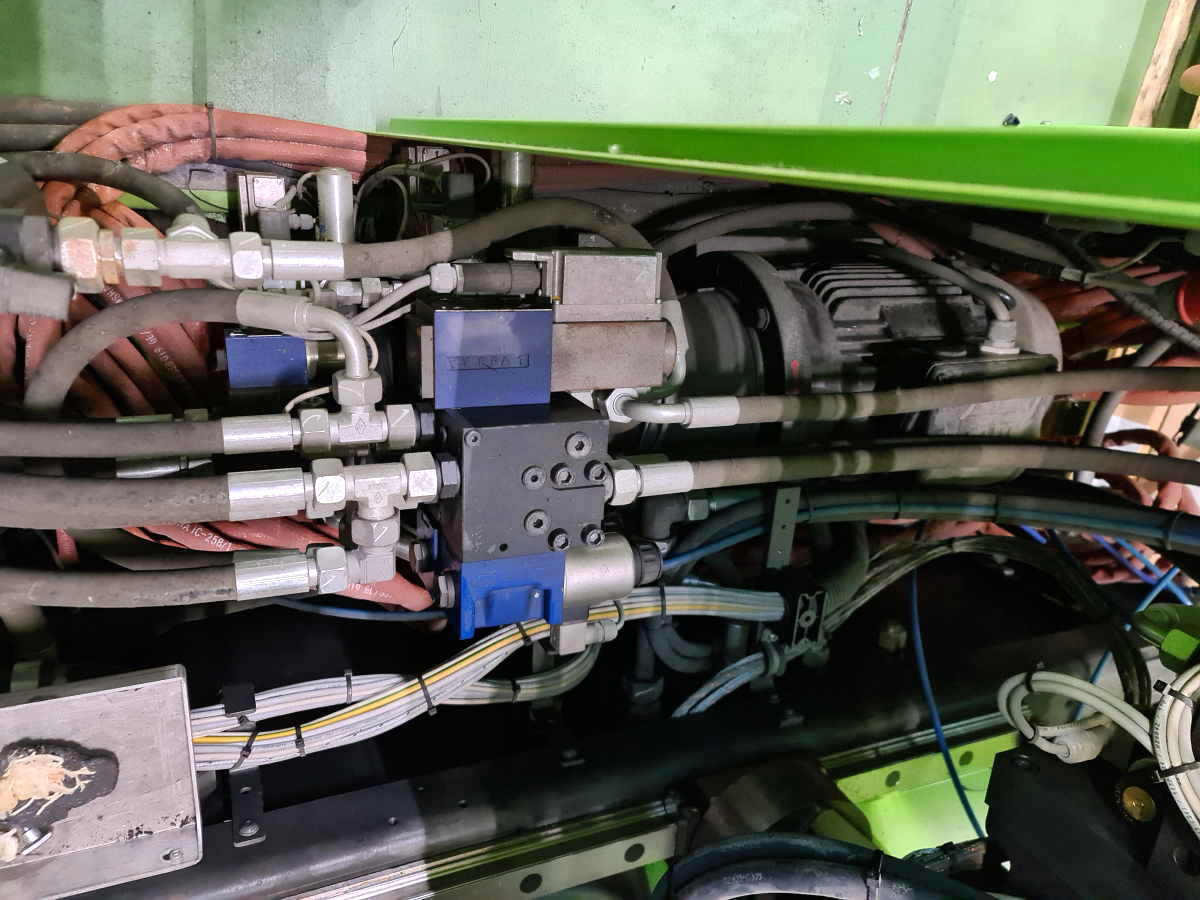

- pump drive power: 15 kW

- material hopper capacity: 3 l

- material feeding capacity: 50 kg/h

- oil thermostat tank capacity: 8 l

- oil thermostat operating temperature range: 20-160 °C

- maximum drying capacity: approx. 25 kg/h

- maximum drying temperature: 140 °C

- power of plastic dryer: 2 kW

- cooling capacity: 6.6 kW

- fan capacity: 6100 m3/h

- INSERT 60H/30 SHUTTLE machine power supply: 3x 400 V; 50 Hz

Equipment of the injection moulding machine

- CNC control: ENGEL CC300

- plastic dryer: PIOVAN DS503+T30

- plastic feeder: PIOVAN S50

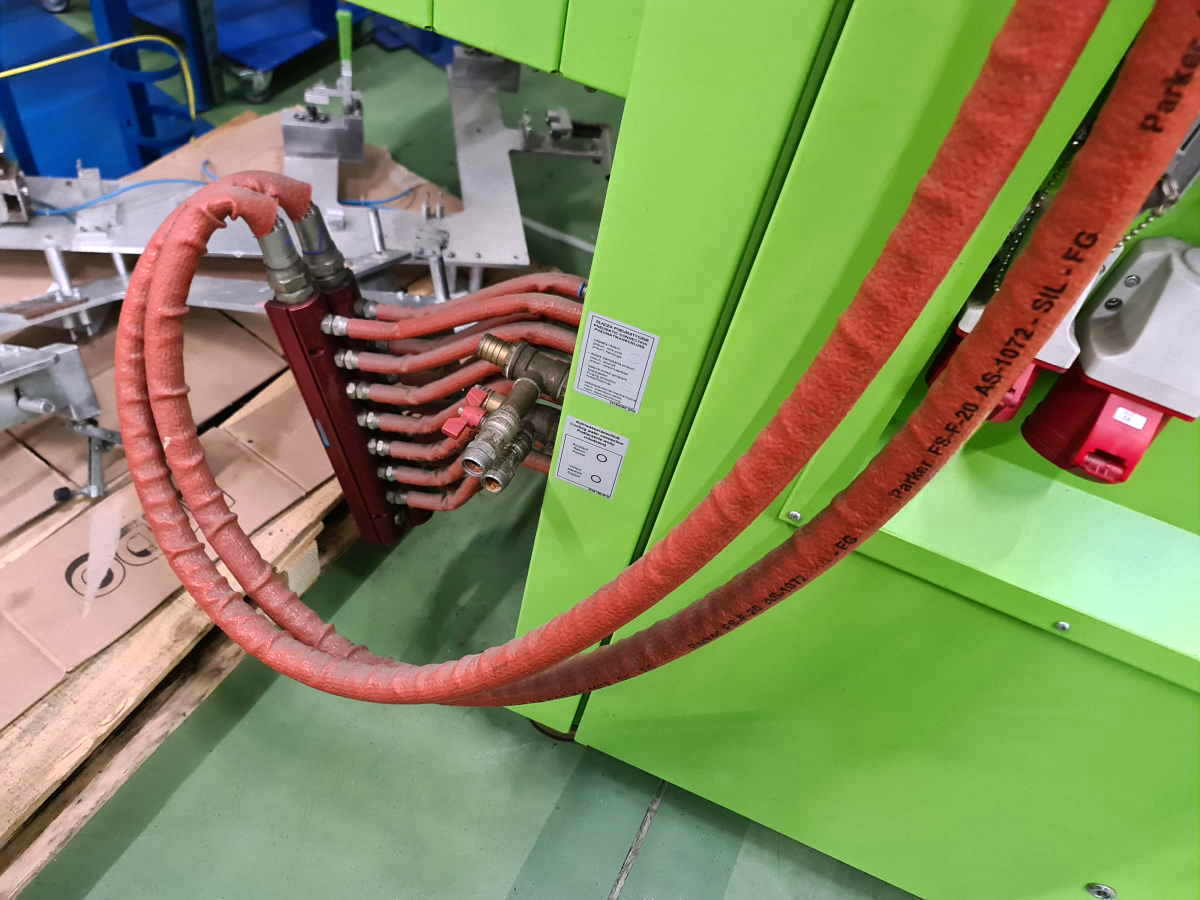

- mould temperature controller: ENGEL flomo

- material hopper: PIOVAN T3M

- 2-position hydraulic sliding table

- cooler: PIOVAN CH50

- oil thermostat: PIOVAN TO 112

- clamping platens with 125 mm diameter centering hole, type EUROMAP

- oil filter station OM 1.0

- central ejector on both stations of the sliding table

- photocell for rapid mould installation/removal by the operator

- contact-free travel sensors

- magnetic air valve

- standard check valve R9b

- ring check valve

- mechanical mould closing protection

- ceramic heating elements

- USB interface

- Ethernet interface

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe