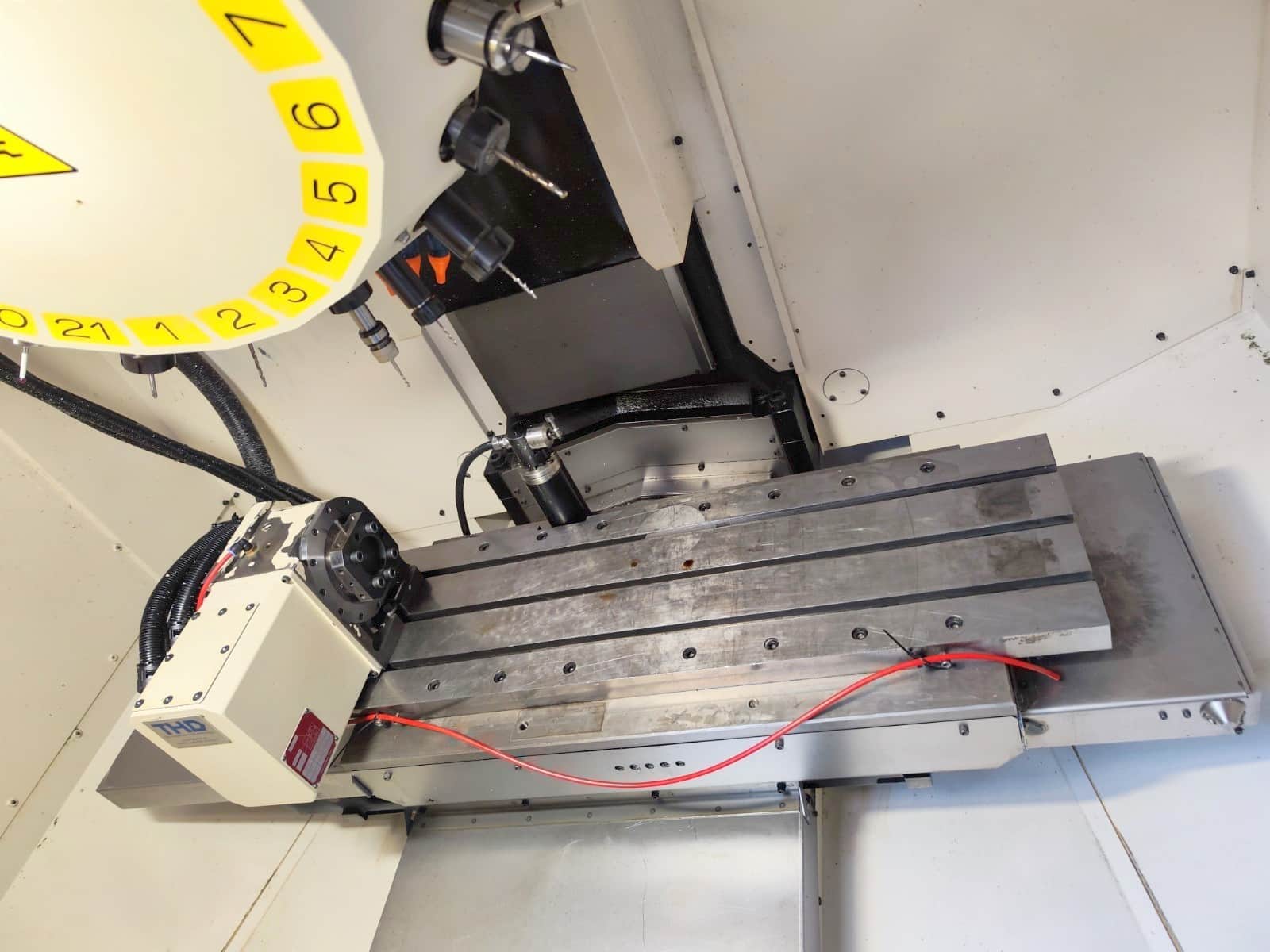

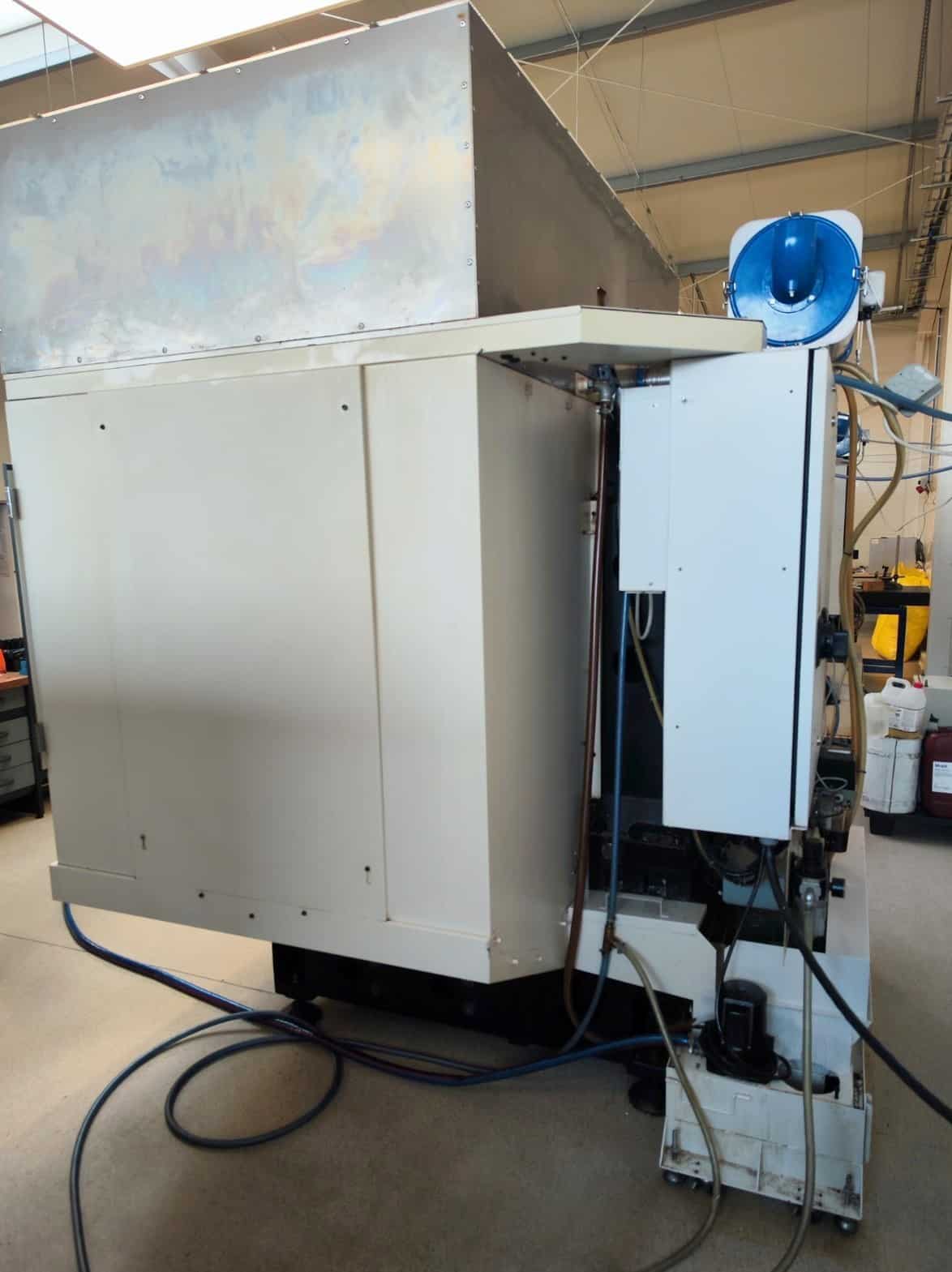

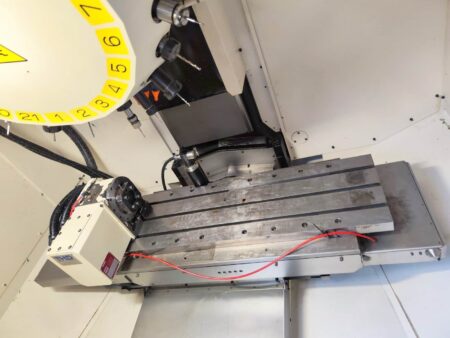

FANUC ROBODRILL Alpha-T21iEL CNC vertical machining centre was built in 2007 in Japan. The machine used for machining workpieces with a maximum weight of 300 kg, is characterised by its versatility and high accuracy, which guarantees excellent machining results during mass production as well as when working in small batches. Thanks to its reliable construction with a reinforced work table with dimensions (L x W) of 850 x 410 mm, the milling process is performed with the highest precision and, most importantly, without any interruptions.

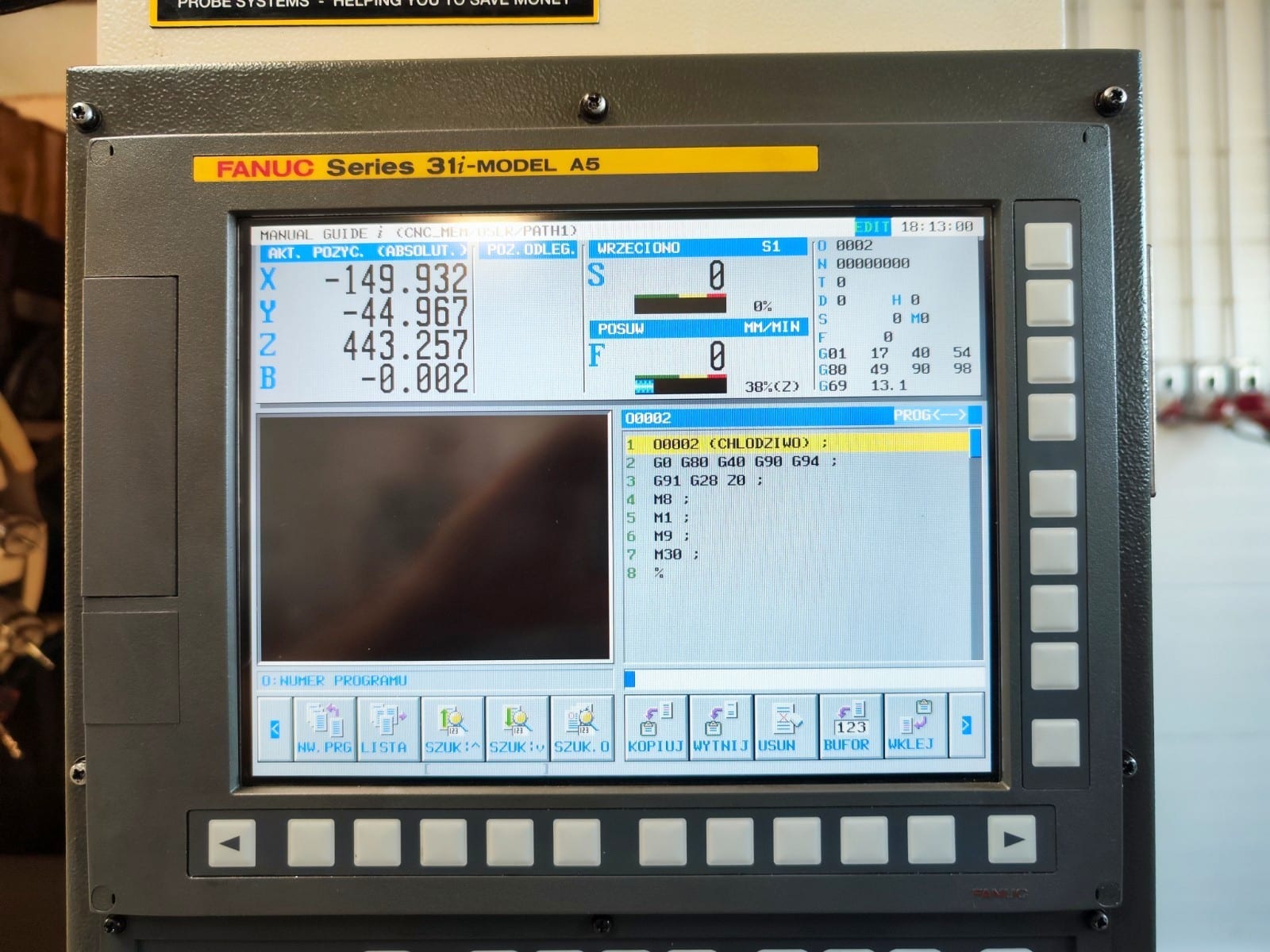

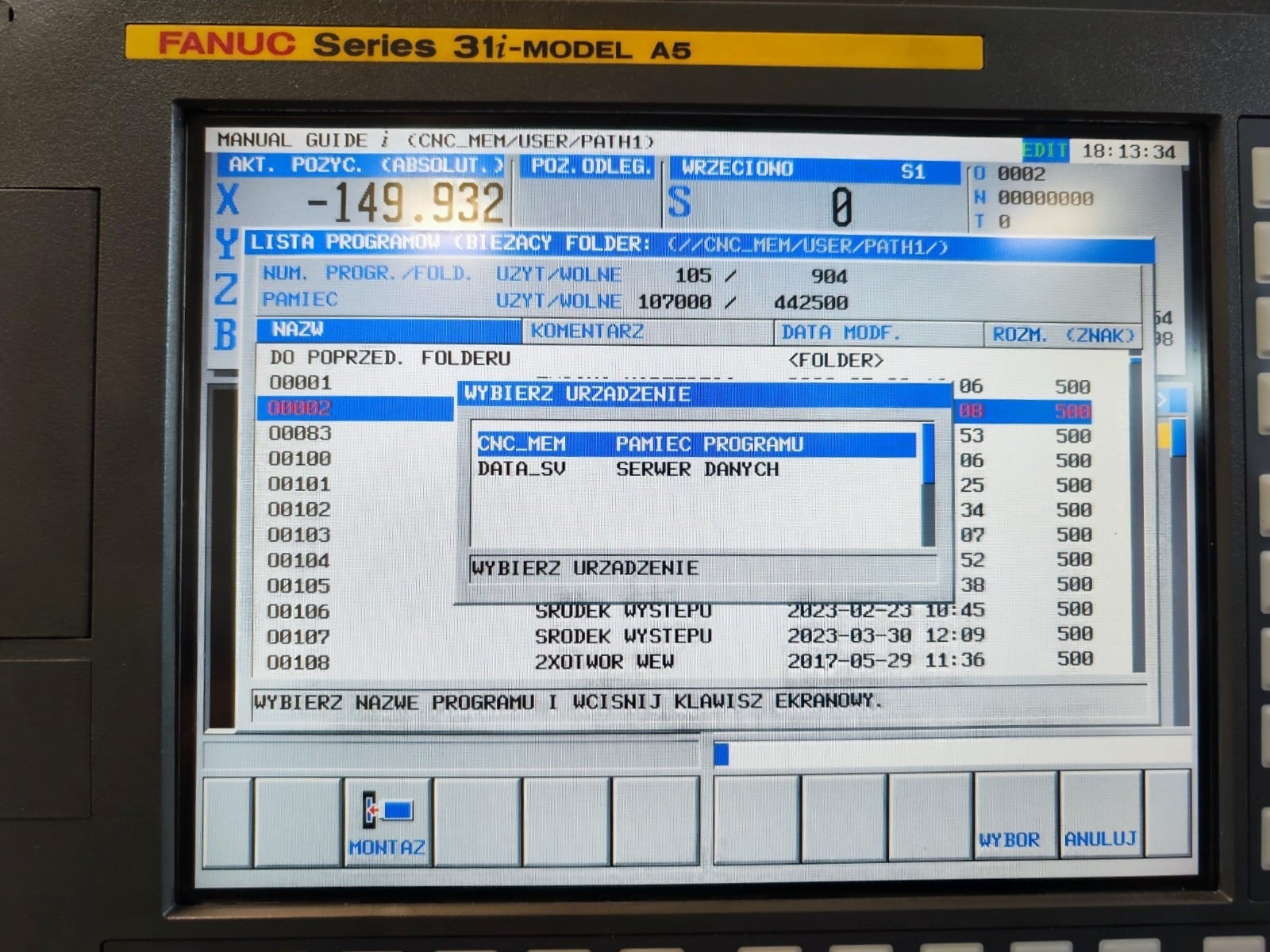

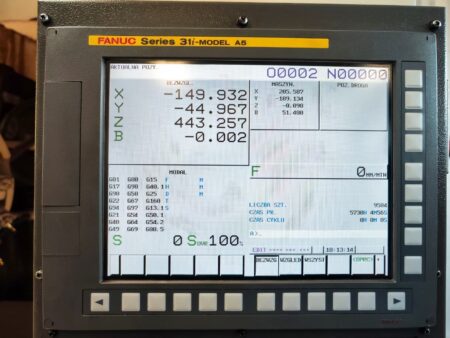

Machining programmes are created in just a few steps using the intuitive, ISO code-format-based FANUC MANUAL GUIDE i software and with an interactive interface and graphical simulations. The software reduces the time from drawing up the technical drawings to the start of production, resulting in increased machine productivity, easier operation and a guarantee of excellent results even when performing complex machining programmes.

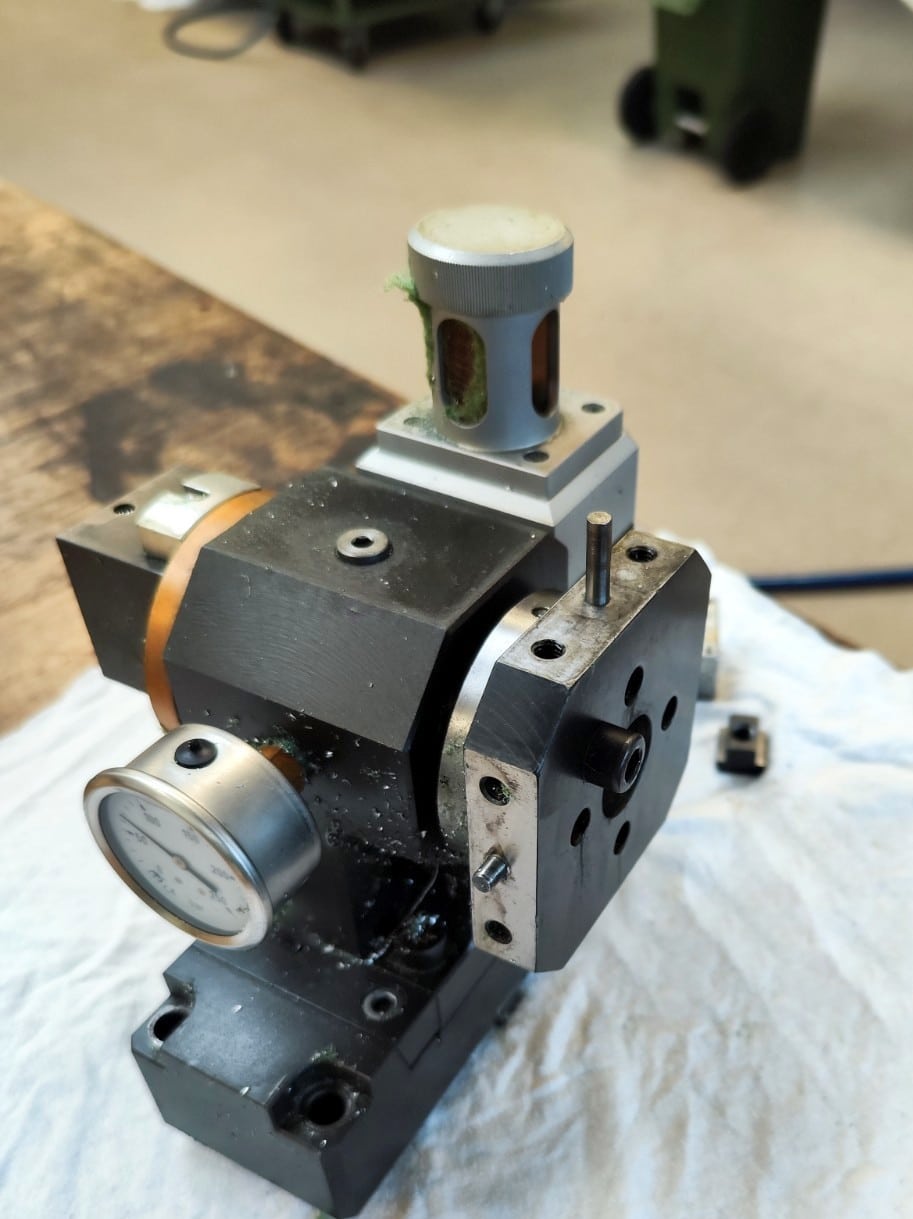

The FANUC ROBODRILL Alpha T21iEL machining centre performs four-axis machining, thanks to the high-speed and high-performance TSUDAKOMA RNA-160L tilt-rotary table with rotary axis B and pneumatic clamping system. The worm gear system included in the rotary table allows the indexing speed to be increased by 20% while maintaining high indexing accuracy.

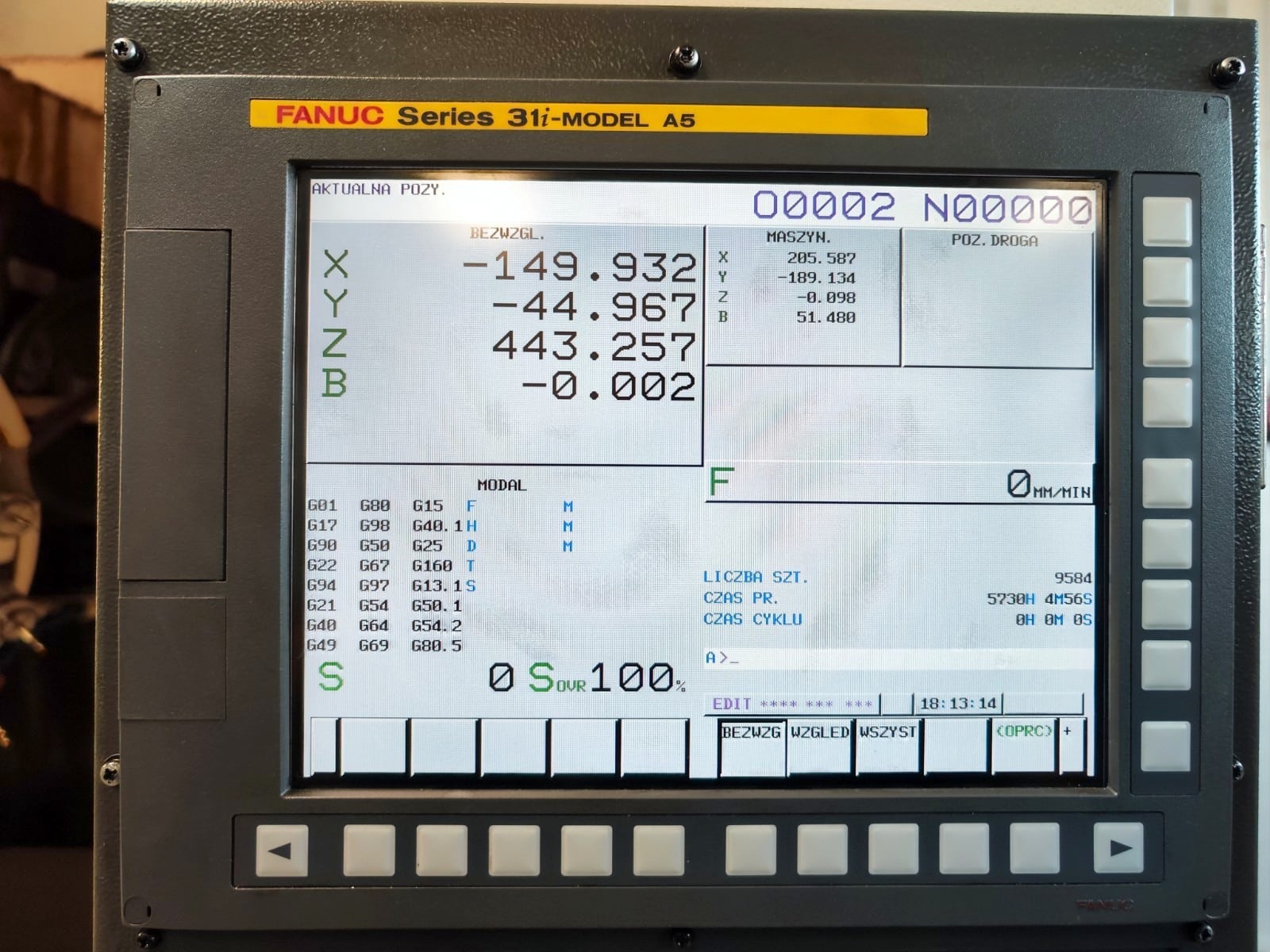

FANUC Series 31i-MODEL A5 CNC control has been enhanced with a number of additional features to increase the milling centre’s range of operation, including ‘AI Contour Control’ to suppress acceleration/deceleration and servo motor delays during feed speed increases. The FANUC ROBODRILL α-T21i milling centre is offered with a wide range of equipment, including the RENISHAW TS27R contact tool setting probe for measuring and detecting broken tools and the RENISHAW OMP40 touch-trigger probe for checking and aligning the workpiece. The total weight of the machine is 2200 kg.

Technical specifications of the FANUC ROBODRILL Alpha-T21iEL CNC milling machine

- work table dimensions (L x W): 850 x 410 mm

- feed rates in the X/Y/Z axis: 700/400/330 mm

- rapid traverse in the X/Y/Z axis: 54 m/min

- working feed rate in the X/Y/Z axis: 1-30000 mm/min

- maximum workpiece weight: 300 kg

- maximum spindle speed: 10000 rpm

- minimum spindle speed: 100 rpm

- spindle power (10 min/constant operation): 5.5/3.7 kW

- positioning repeatability: ± 0.002 mm

- tool head capacity: 21 pcs.

- maximum tool diameter: 80 mm

- maximum tool length: 200 mm

- maximum tool weight: 3 kg

- tool change time: approx. 2 s

- accuracy of positioning in one axis: 0.006/300 mm

- distance between toolholder and work table: 250-580 mm

- coolant tank capacity: 100 l

- power supply: 3x 220 V; 50 Hz

- weight of machine Alpha-T21iEL: 2200 kg

Equipment of the milling machine

- CNC control: FANUC Series 31i-MODEL A5

- touch-trigger probe: RENISHAW OMP40

- contact tool setting probe: RENISHAW TS27R

- rotary tilting table: TSUDAKOMA RNA-160L

- 4th axis (B axis)

- software: FANUC MANUAL GUIDE i

- additional function “helical interpolation”

- additional function “48 additional coordinate systems”

- additional function “Multi Step Skip Function” (Multi Step Skip Function)

- additional function “AI Contour Control I” (analysis of 30 blocks in advance)

- additional function “AI Contour Control II”

- additional function “tool compensation” (Tool Compensation Memory C)

- measurement software

- turret tool head

- column extension by 100 mm

- pneumatic brake support for rotary tilting table

- fourth axis servo motor (B axis): FANUC ALPHA 2/5000iS

- tool holder: DIN 69871 A30

- spindle taper: BT 30

- data server 1 GB

- co-operation with computer network

- cooling system

- lubrication system

- workspace illumination

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe