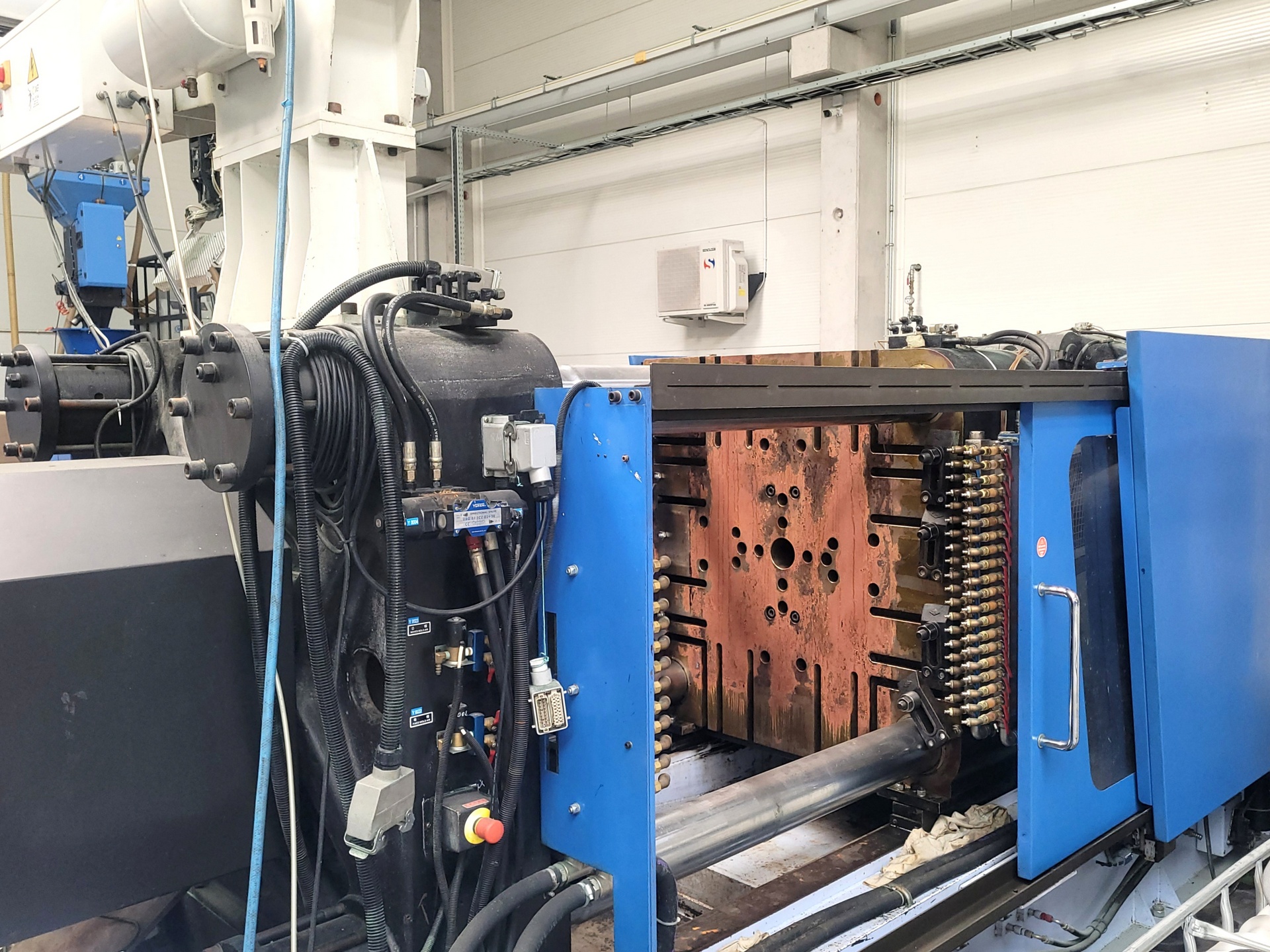

FCS SD-600 M injection moulding machine was built in 2009 in Taiwan by FU CHUN SHIN MACHINERY MANUFACTURE CO., LTD. The machine, distinguished by its high efficiency and reliability, is an excellent choice for the economic production of plastic parts. These parts are produced using the reliable injection moulding method, which involves feeding plasticised plastic into a mould and then clamping it with high press force. A precision mould clamping system operating at a maximum force of 600 tonnes guarantees the high repeatability and quality of the parts produced. In order to fully automate the entire process, a robot works together with the machine. It collects the finished moulded parts from the workspace onto a conveyor belt at the end of the process. The FCS SD 600 M injection moulding machine weighs 24 tonnes.

Technical specifications of the FCS SD-600 M injection moulding machine

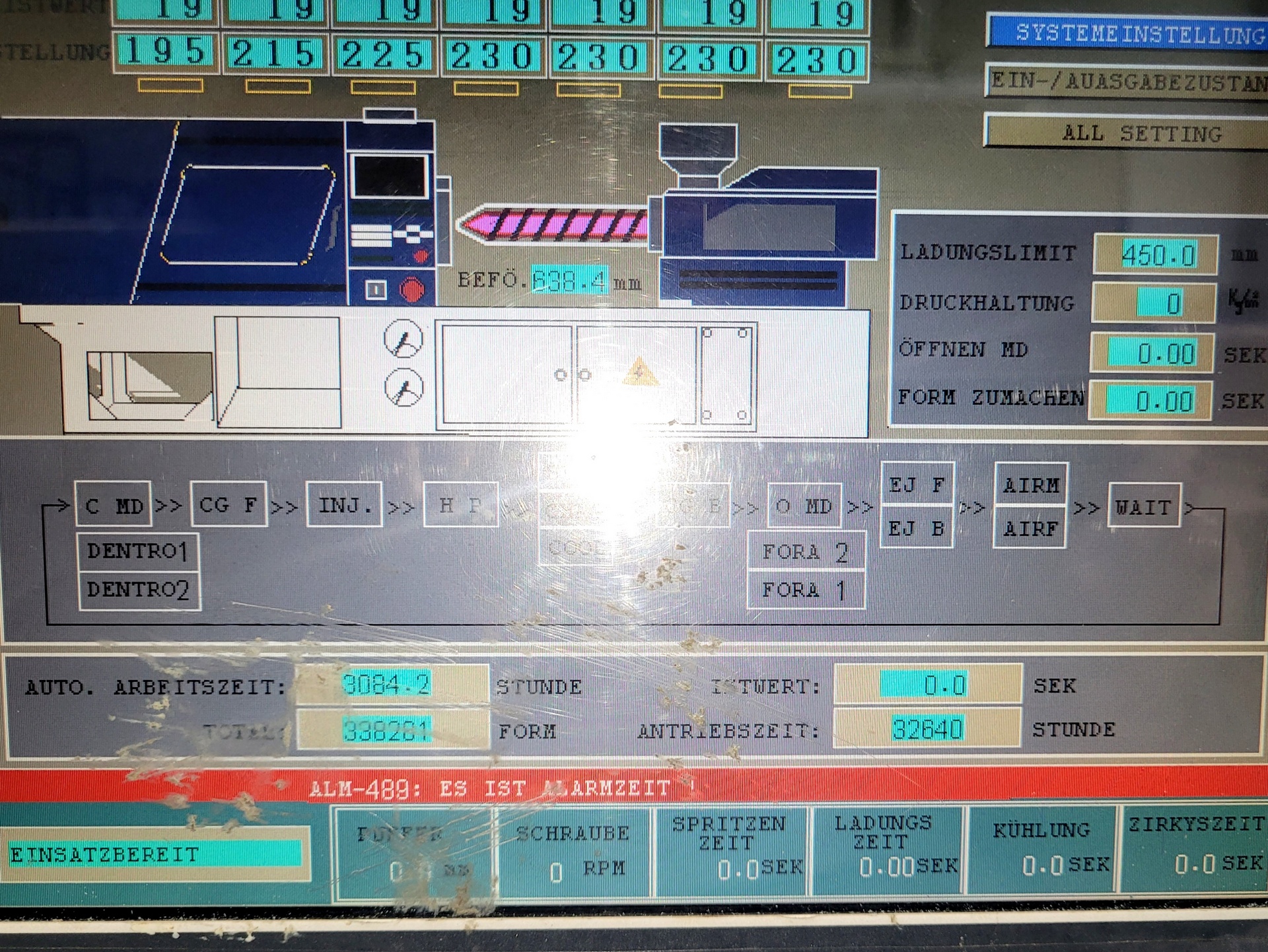

- control system: FCS-3000

- mould clamping force: 600 t

- mould clamping stroke: 990 mm

- screw diameter: 95 mm

- screw rotational speed: 160 rpm

- maximum injection pressure: 1241 kgf/cm2

- injection volume: 2691 cm3

- maximum injection weight PS: 2435 g

- injection rate: 673 cm3/s

- plasticisation capacity: 470 Kd/h

- injection speed: 95 mm/s

- injection stroke: 380 mm

- minimum mould dimensions: 560 x 560 mm

- mould thickness: 300-1100 mm

- distance between tie bars: 860 x 860 mm

- clamping platen dimensions: 1290 x 1290 mm

- ejector stroke: 220 mm

- robot: WELDOM

- conveyor belt

- cooling device (chiller): RIOU RO-30A

- temperature controller in the range 0-400°C (7 pcs.)

- heating power: 46.68 kW

- main motor power: 44 kW

- maximum pump motor power: 75 kW

- pump pressure: 140 kg/cm2

- oil tank capacity: 1190 l

- dimensions (L x W x H): 8500 x 2200 x 2680 mm

- weight of the FCS SD-600 M machine: 24000 kg

(The technical parameters given may differ slightly from reality. A verification with the actual capabilities of the offered machine is required.)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe