FEINTOOL GKP F 100T fine blanking press was manufactured in Switzerland in 1974. The machine, distinguished by its robust, stable design, can perform several demanding machining steps in one precise process, saving time and labour. Workpieces with a maximum thickness of 6 mm thus achieve an extremely even surface and precisely defined edges that are impossible to achieve on other machines. The machining process can be fully automated when the FEINTOOL GKP F 100/160 hydraulic blanking press is retrofitted with a sheet metal feeder. The total weight of the machine is approximately 9 tonnes.

Technical data of the FEINTOOL GKP F 100T hydraulic press

- maximum workpiece thickness: 6 mm

- maximum sheet metal width: 210 mm

- total force including auxiliary functions: 160 t

- shearing force: 100 t

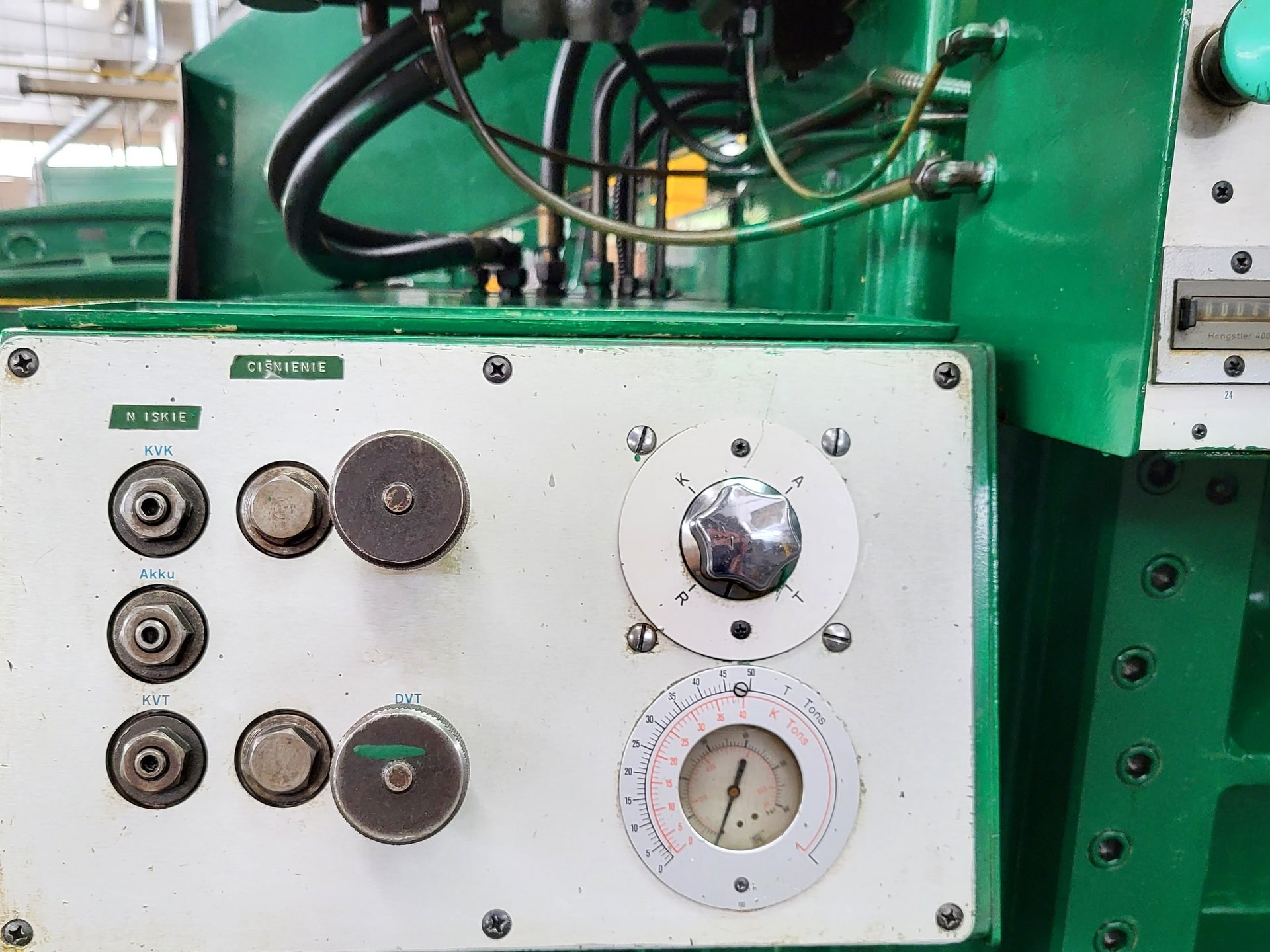

- hydraulic counterweight force (upper table): 1-40 t

- hydraulic force of ring jaw (lower table): 12-50 t

- ejection force (pump pressure): 4-8 t

- maximum number of slider strokes: 72/min

- minimum number of slider strokes: 18/min

- stepless adjustment of stroke rate

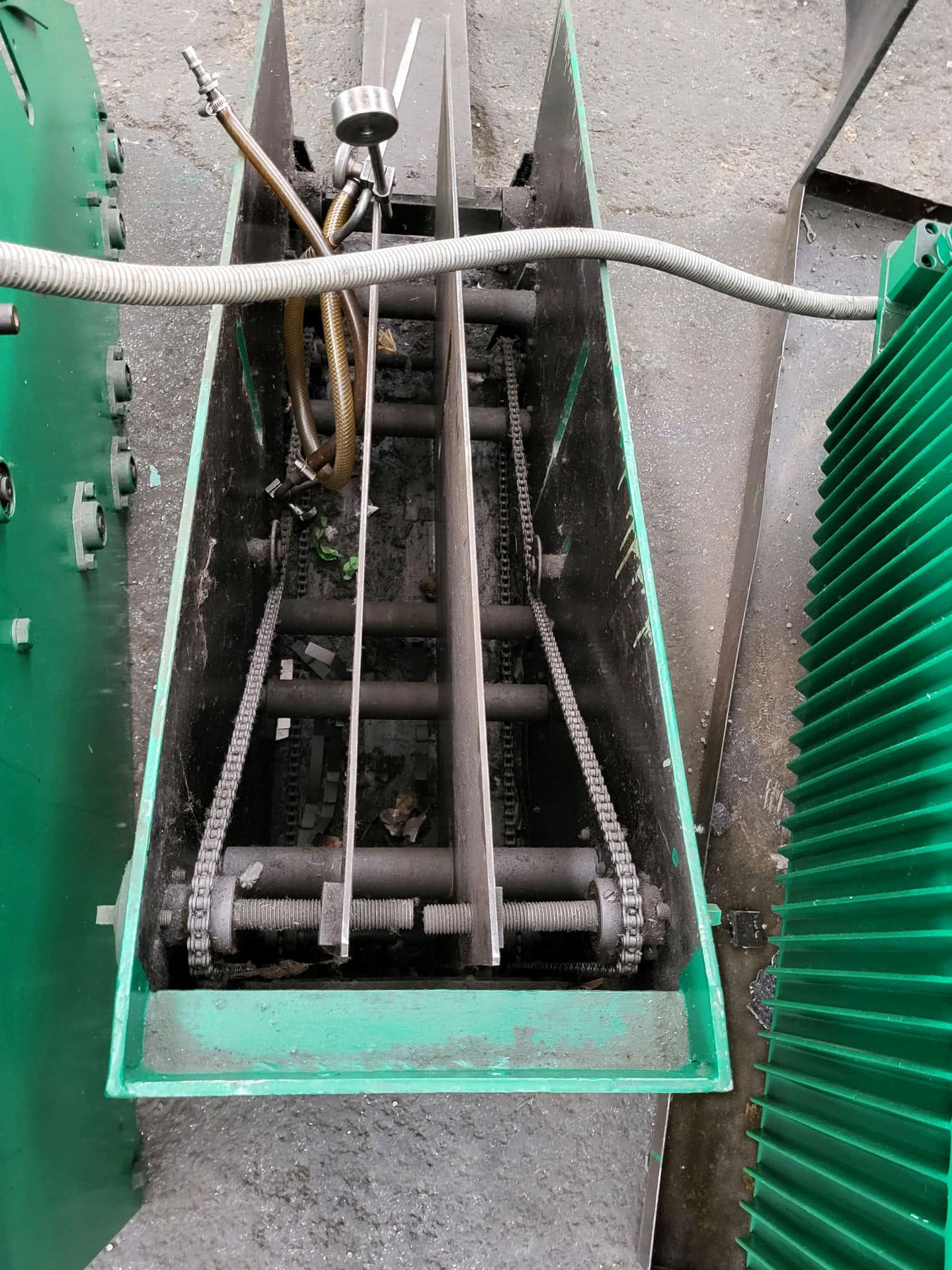

- channel for collecting finished workpieces

- hydraulic upper table lock

- lubrication device for sheet metal

- blow-out device

- motor power 7.5 kW

- pump motor power (pneumatic shears): 4 kW

- pump motor power (hydraulic shears): 5.5 kW

- compressed air pressure: 6-8 bar

- power supply: 380 V; 50 Hz

- dimensions (W x H): 1780 x 2800 mm

- weight of machine: approx. 9 t

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe