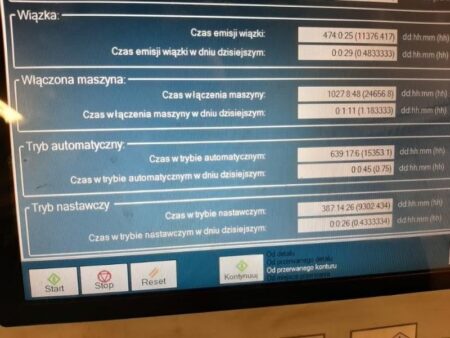

Fiber EAGLE INSPIRE 1530 F6.0 laser was produced in 2015 in Poland by the POWER-TECH brand. It is equipped with numerical control Beckoff TwinCAT CNC. Laser source Ytterbium Fiber laser YLS of the German company IPG has a power of 6 kW, which allows cutting steel with a maximum thickness of 25 mm (structural steel and stainless steel). The cutter also has dynamic linear motors on all axes. The machine body is made of polymer concrete and the crossbeam is made of carbon fiber. The range of movements in the X, Y and Z axes is 3060 mm, 1540 mm and 100 mm, respectively, enabling the processing of a detail with a maximum weight of 900 kg. The machine has two tables with dimensions of 1500×3000 mm. The laser cutter achieves a cutting speed of up to 150 m / min, as well as an acceleration of 6G. This guarantees maximum quality, accuracy and cutting efficiency. The machine is ideal for mass production and machining, such as punching elements for electric motors or elements with complex forms. The efficiency of work is also influenced by a very fast pallet changer.

Technical parameters of the Fiber EAGLE INSPIRE 1530 F6.0 laser cutter

– power: 6000 W

– table dimensions: 3000×1500 mm

– number of tables: 2

– control: Beckoff TwinCAT CNC

– PC system: Windows 7 PL

– laser source: Ytterbium Fiber laser YLS from the German company IPG with a power of 6kW

Sheet cutting range:

– structural steel: from 0.5 mm to 25 mm

– stainless steel: from 0.5 mm to 25 mm

– aluminum: from 0.5 mm to 20 mm

– copper: from 0.5 mm to 10 mm

– brass: from 0.5 mm to 12 mm

– bronze: from 0.5 mm to 5 mm

Work area:

– X axis 3060 mm

– Y axis 1540 mm

– Z axis 100 mm

– max. sheet weight 900 kg

Machine dimensions and weight:

– length 10,000 mm

– width 3080 mm

– height 3060 mm

– weight 18100 kg

Maximum speeds:

– parallel to the X, Y, Z axes: 250 m / min

– simultaneously: 350 m / min

Axis parameters:

– repeatability 0.03 mm

– cutting accuracy 0.05 mm

– accelerations of 60 m / s2

– min. programmable stroke 0.001 mm

Benefits of a fiber laser

– high cutting accuracy thanks to the traverse made of carbon fiber

– maximum work efficiency thanks to linear drives

– innovative methods of safe metal processing

– hail-free cutting of electromagnetic sheets thanks to a refined process

– guiding the laser beam with a failure-free optical fiber

– efficient processing of highly reflective steels such as brass, copper and special steels

– modern, easy-to-use software

– high energy efficiency

– fiber laser

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano