FINN-POWER SG-6 turret punch press was built in 1999 in Finland by LILLBACKA CORPORATION. The machine has been regularly serviced throughout its service life.

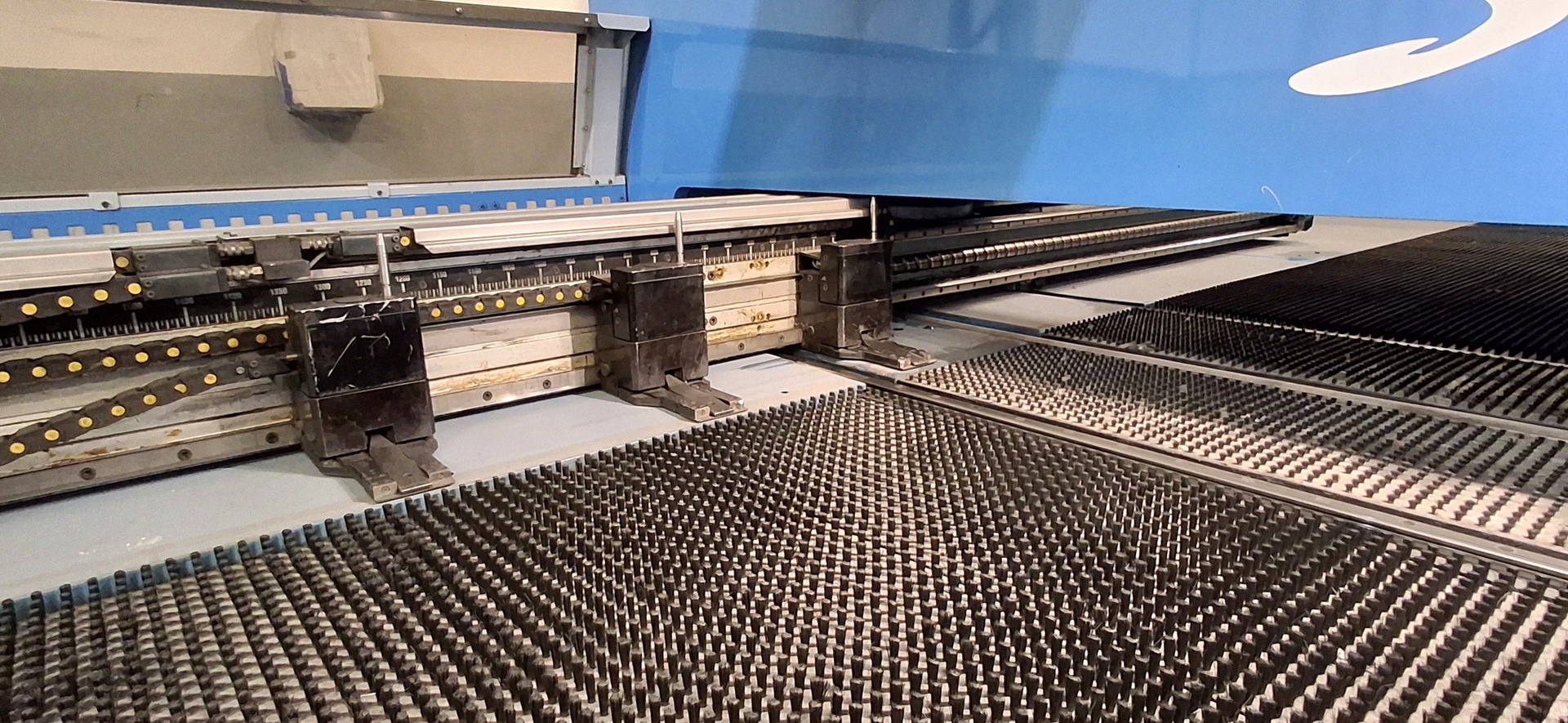

The FINN-POWER Shear Genius SG6 was created as an answer to the daily challenges of modern business. This system is designed for precision punching, stamping and cutting of sheet metal with a maximum length of 3061 mm and a width of 1528 mm. The integration of all the necessary equipment in a single place enables significant reductions in production costs as well as overall working time.

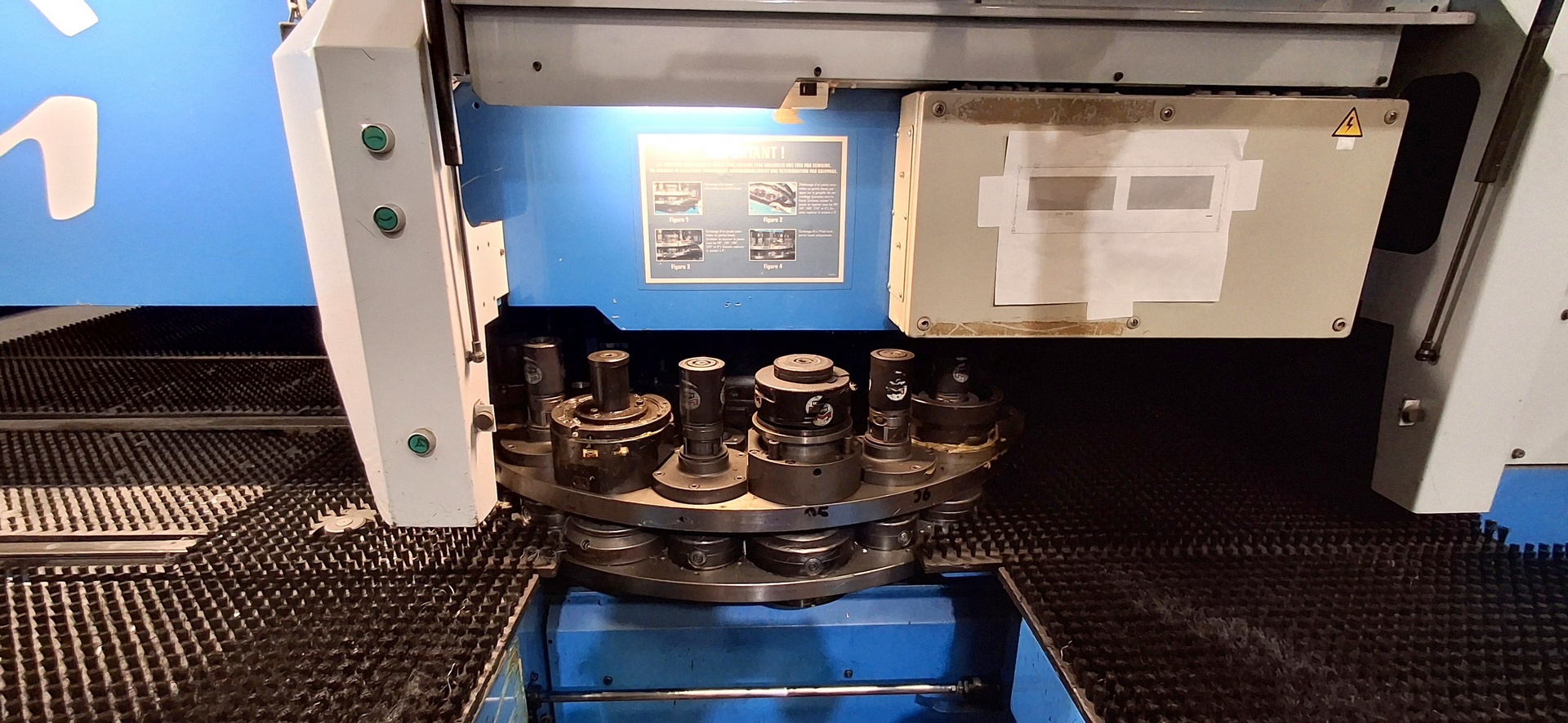

All machining processes are performed fully automatically, in a single work cycle. The loading system separates a single sheet from the stack and fixes it in pneumatic clamps. The holes are punched by means of reliable tools taken from the 20-station turret. Parameters such as stroke depth, stroke length and stroke speed can be fully adapted to the individual tools. Once punching is complete, the workpiece is moved to the cutting shears. The finished parts are then placed on a conveyor and transported out of the working area.

The FINN-POWER SG6 CNC punching machine is offered with extensive equipment, which includes e.g. tools, a hydraulic unit and an intelligent CNC control. The control system is distinguished by its simple operation and all necessary functions. The FINN-POWER Shear Genius turret punching machine weighs 22000 kg.

Technical specifications of the FINN-POWER SG-6 punching machine

General data

- punching force: 30 t (300 kN)

- feed in the X/Y axis: 2584/1560 mm

- maximum feed rate in the X/Y axis: 80/60 m/min

- maximum transverse feed rate: 100 m/min

- maximum sheet metal dimensions (L x W): 3061 x 1528 mm

- maximum sheet metal weight: 200 kg

- number of strokes (1 mm hole spacing): 1000/min

- number of strokes (25 mm hole spacing): 440/min

- number of strokes (250 mm hole spacing): 150/min

- maximum tool diameter: 89 mm

- number of tool stations: 20 – including:

- maximum tool rotational speed: 58 rpm

- tool exchange time: 1-3 s

- turret rotation speed: 30 rpm

- maximum hole position deviation: 0,1 mm

- maximum hole spacing deviation: ± 0,05 mm

- maximum angular deviation: ± 0,1°

- Pa position deviation: 0,08 mm

- Ps spread deviation: 0,04 mm

- operating hours: 37341 h

- maximum operating pressure: 300 bar

- minimum compressed air pressure: 6 bar

- average compressed air consumption: 30 Nl/min

- oil tank capacity: 330 l

- maximum oil cooler power consumption: 30 kW

- oil cooler air flow: 2.9 m3/s

- average power consumption: 30 kW

- power supply: 3x 400 V; 50 Hz

- weight of the FINN-POWER SG-6 machine: 22000 kg

– MT10 station: 1

– B station: 11

– Bi station: 1

– C station: 3

– Ci station: 2

– D station: 1

– Di station: 1

Integrated cutting shears

- cutting force: 25 t (250 kN)

- maximum cutting thickness (aluminium): 5 mm

- maximum cutting thickness (Fe52/Fe37 steel): 4 mm

- maximum cutting thickness (stainless steel): 3 mm

- minimum cutting thickness: 0.5 mm

- maximum sheet metal dimensions (L x W): 1528 x 800 mm

- blade gap adjustment: manual

Equipment of the FINN-POWER TRS 6 FBU punching machine

- CNC controller

- integrated cutting shears

- automatic sheet metal loading system

- brush table

- pneumatic clamps for material (3 pcs)

- conveyor for finished parts

- waste conveyor

- hydraulic unit

- tools (15 pcs)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe