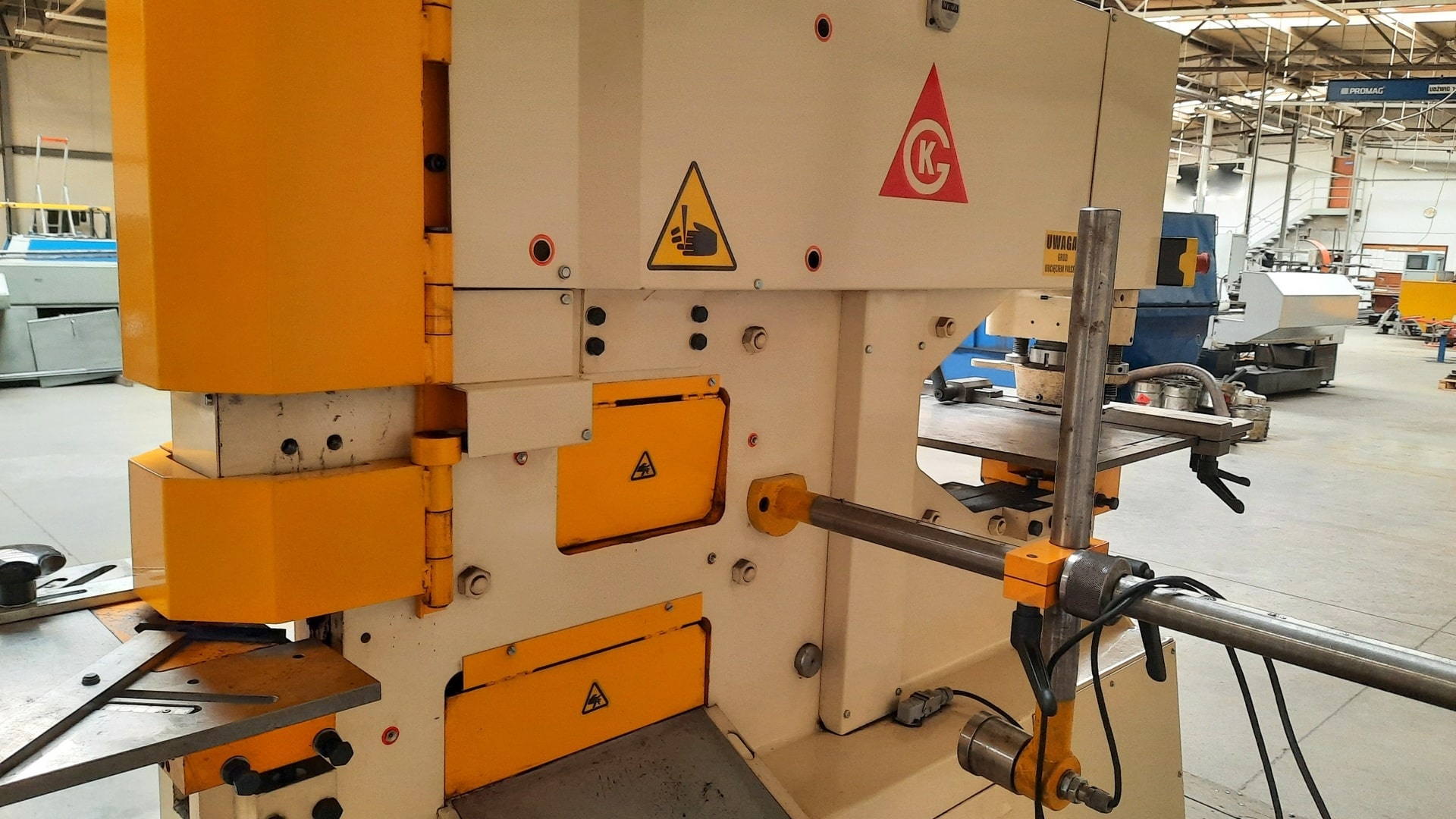

GEKA BENDICROP 60 SD ironworker machine was manufactured in 2016 in Spain. Equipped with 5 work stations, the ironworker machine performs precise hole punching, corner cutting, flat bar cutting, as well as bar cutting and bending. The vertical movement of the shears is performed by two adjustable hydraulic cylinders with a central positioned actuator, which guarantees excellent cutting quality throughout the entire life of the machine. The GEKA ironworker machine weights 1750 kg.

Technical specifications of the GEKA BENDICROP 60 SD hydraulic ironworker machine

General data

- maximum press force: 60 t

- number of cylinder strokes: 32/min

- dimensions (L x W x H): 2010 x 1400 x 2006 mm

- weight of machine BENDICROP 60 SD: 1750 kg

Hole punching station

- maximum bore size (diameter x thickness): ø 40 x 11 mm

- throat depth: 500 mm

- additional table for hole punching fi 100 mm

- table working height: 1106 mm

Angle bars and solid bars shearing station

- cutting of angle bar at 90°: 120 x 120 x 10 mm

- maximum round bar diameter: ø 45 mm

- maximum square bar diameter: 40 mm

- cutting working height: 1077 mm

Triangular notching station

- maximum notching thickness: 10 mm

- maximum angle bar notching: 100 x 100 x 10 mm

- table working height: 1039 mm

Flat bar shearing station

- maximum flat bar size: 350 x 10 mm

- maximum flat bar size with 5° deformation: 350 x 15 mm

- knife length: 356 mm

- table working height: 859 mm

Flat bar bending press

- maximum flat bar dimensions (width x thickness): 150 x 10 mm

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe