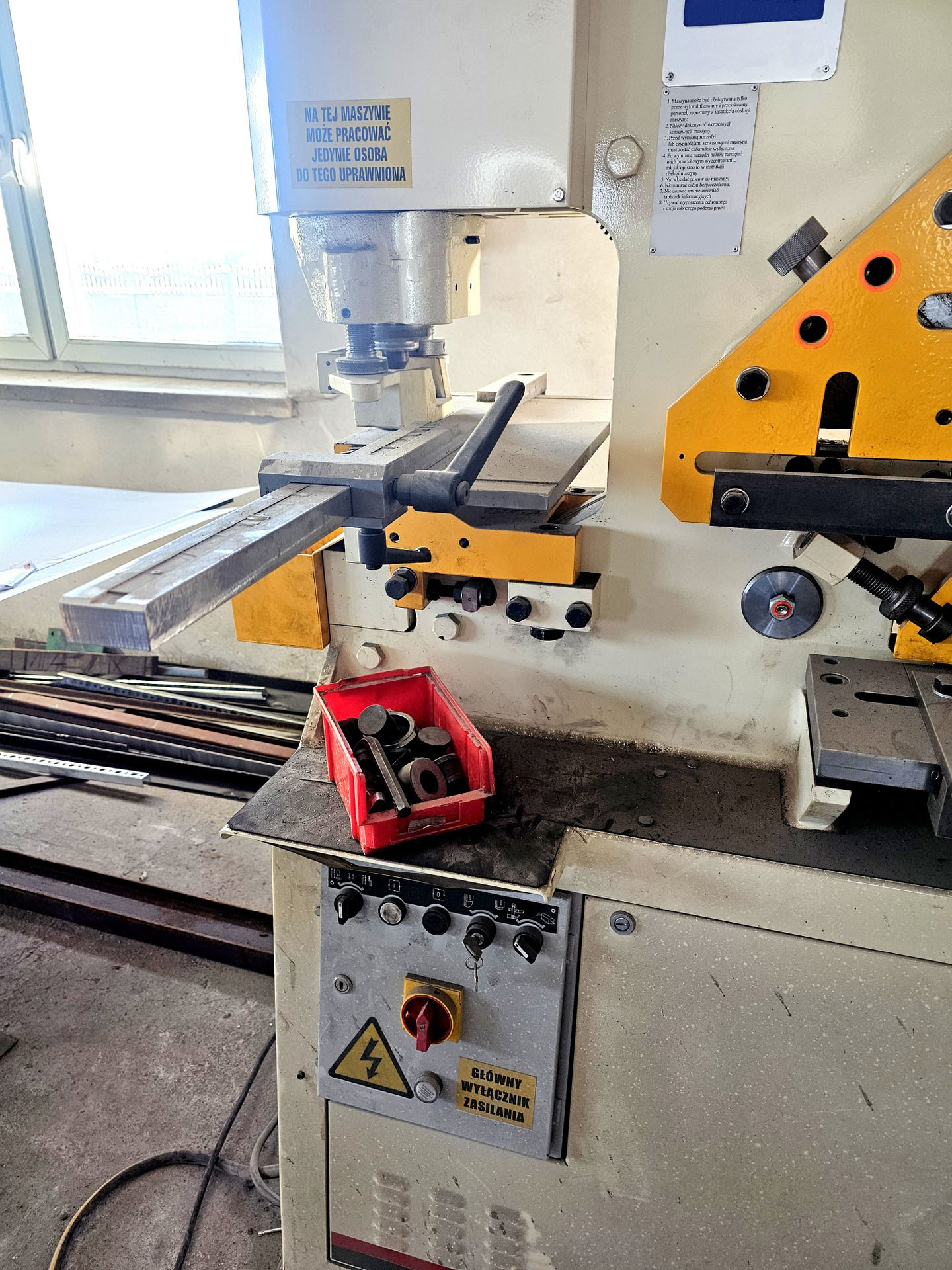

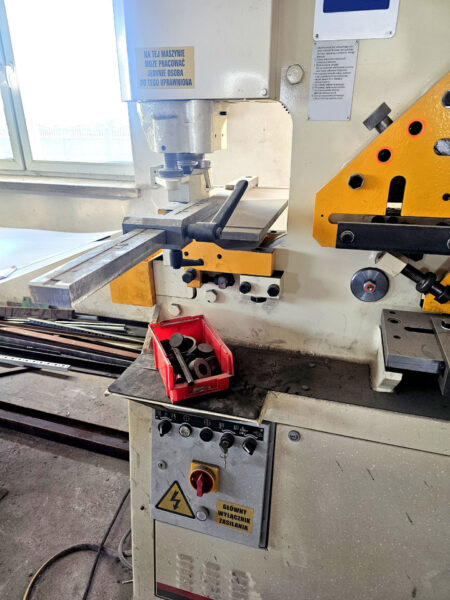

GEKA HYDRACROP 55/S hydraulic ironworker machine was built in Spain in 2022 by MAQUINARIA GEKA S.L.U. This machine, distinguished by its extensive machining capabilities, is intended for precise hole and corner punching as well as shearing flat bars, angles and solid bars. Each of the 5 work stations is controlled by two hydraulic cylinders, which enable independent or parallel operation at two stations simultaneously. All this makes the offered GEKA HYDRACROP 55 S ironworker machine the perfect choice to significantly increase the productivity of any industrial plant. GEKA HYD 55 S weighs 1200 kg.

Technical specifications of the GEKA HYDRACROP 55/S 2-cylinder ironworker machine

General data

- maximum punching force: 55 t

- maximum cutting force: 110 t

- number of workstations: 5

- number of hydraulic cylinders: 2

- total power: 5.5 kW

- power supply: 400 V; 50 Hz

- weight of the GEKA HYDRACROP 55/S machine: 1200 kg

Flat bar shearing station

- flat bar dimensions: 300 x 15 mm; 200 x 20 mm

- blade length: 305 mm

- working height: 880 mm

Angle bar shearing station

- angle bar dimensions (shearing at 90°): 120 x 120 x 10 mm

- angle bar dimensions (shearing at 45°): 70 x 70 x 7 mm

- working height: 1068 mm

Square and solid bar cutting station

- solid bar diameter: ø 40 mm

- square bar diameter: 40 mm

- working height: 1100 mm

Rectangular notching station

- maximum notching thickness: 10 mm

- maximum notching dimensions: 100 x 100 x 10 mm

- blade length: 90 mm

- blade width: 42 mm

- working height: 942 mm

Hole punching station

- maximum hole diameter (10 mm sheet metal thickness): 40 mm

- maximum hole diameter (20 mm sheet metal thickness): 20 mm

- throat clearance: 250 mm

- maximum punch stroke length: 60 mm

- working height: 1085 mm

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe