GILDEMEISTER CTX 310 CNC turning center was built in 2002. The machine, distinguished by its stable, robust construction, is designed for precision machining of workpieces with a maximum diameter of 330 mm. Workpiece turning is performed inside a large work area, using reliable components in the form of a high-speed spindle and cutting tools taken from a 12-position turret. Extensive equipment, including, among others, a 3-jaw chuck and driven tools, allows for fully automatic machining with excellent performance and low operating costs. The CTX 310 CNC lathe weights 3200 kg.

Technical specifications of the GILDEMEISTER CTX 310 lathe

- turning diameter above the bed: 330 mm

- turning diameter above cross slide: 260 mm

- turning length: 450 mm

- maximum shaft diameter: 52 mm

- maximum spindle rotational speed: 5000 rpm

- spindle clearance: 68.5 mm

- spindle power: 7.5 kW

- tool holder: VDI 30

- power supply: 400 V; 50 Hz

- dimensions (L x W x H): 4173 x 1594 x 1730 mm

- weight of machine: 3200 kg

Equipment of the GILDEMEISTER turning center

- CNC control: HEIDENHAIN 4290

- 12-position turret

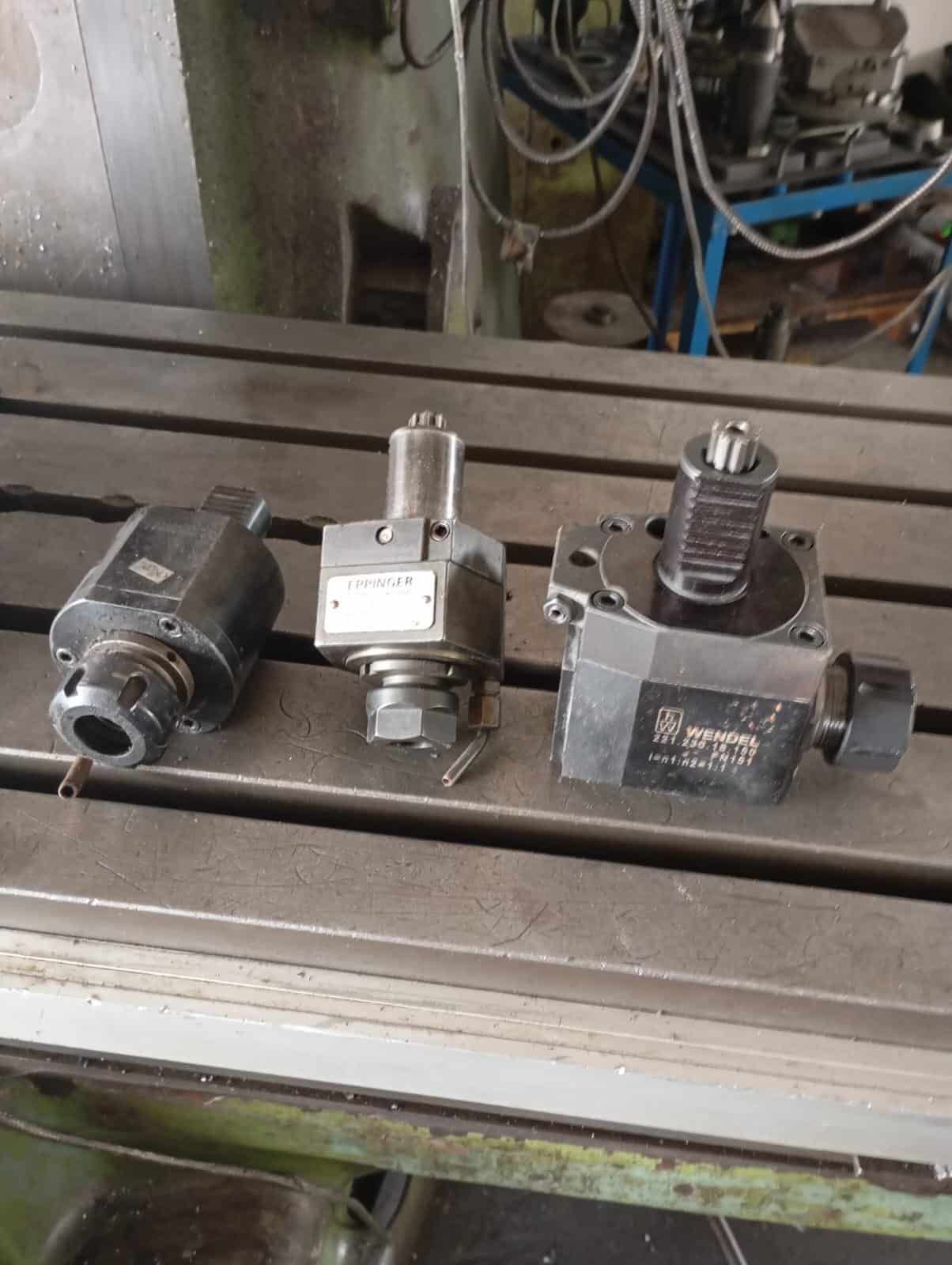

- driven tools (6 pcs.)

- 3-jaw chuck fi 160 mm with 45 mm clearance

- C axis

- chip conveyor

- cooling system

- workpiece receiver

- machine manual

- DTR – Technical and Operating Documentation

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe