GILDEMEISTER MF TWIN 65 Y CNC lathe built in 1999 in Germany allows for fully automated production processes while maintaining high accuracy and low operating costs. The machine distinguished by its extensive machining capabilities, thanks to its sturdy design, extensive equipment and focus on high productivity, is ideal for any production facility, even during the most demanding challenges.

The MF TWIN 65Y CNC turning centre performs precision machining of metal workpieces with a maximum diameter of 200 mm, using reliable tools located in two 12-position tool heads (upper and lower). Workpiece turning takes place inside a large work area equipped with a rigid bed inclined by 45° and an integrated chip conveyor designed to keep the work area clean by constantly removing the chips into a special container located next to the machine. The GILDEMEISTER MF TWIN 65 CNC dual-spindle lathe is also equipped with, among others, a workpiece conveyor, IRCO SiMag bar feeder, Y axis and additional tooling. The total weight of the machine is approximately 6500 kg.

Technical specifications of the GILDEMEISTER MF TWIN 65 Y lathe

General data

- swing over bed: 240 mm

- maximum workpiece diameter: 200 mm

- feed rates in the X/Y/Z axis: 190/40/555 mm

- rapid traverse in the X/Y/Z axis: 20/7.5/30 m/min

- X/Y/Z axis resolution: 0.001 mm

- feed force in the X/Y/Z axis: 400/700/700 daN

- bed inclination angle: 45°

- distance between spindles: 800 mm

- guideway type: roller guideways

- power supply: 3x 400 V; 50 Hz

Main spindle

- rotational speed range: 25-5000 rpm

- rated rotational speed: 850 rpm

- maximum bar diameter: 65 mm

- spindle bore: 79 mm

- spindle end: 170 h5 mm

- clamping chuck maximum diameter: 200 mm

- face bearing diameter: 120 mm

- power (40/100% ED): 28/21 kW

- maximum torque (40/100% ED): 320/240 Nm

- C axis

- rapid traverse in the C axis: 250 rpm

- C axis torque: 200 Nm

- C axis resolution: 0,025°

Sub-spindle

- rotational speed range: 31-6300 rpm

- rated rotational speed: 1000 rpm

- maximum bar diameter: 42 mm

- spindle bore: 56 mm

- spindle end: 140 h5 mm

- clamping chuck maximum diameter: 200 mm

- face bearing diameter: 90 mm

- power (40/100% ED): 18/14 kW

- maximum torque (40/100% ED): 130/173 Nm

- C axis

- rapid traverse in the C axis: 250 rpm

- C axis torque: 120 Nm

- C axis resolution: 0,025°

Tool heads

- capacity (upper head / lower head): 12/12

- rotational speed range: 40-4200 rpm

- DIN 69880 toolholder diameter: 30 mm

- power (40/100% ED): 7/5 kW

- maximum torque (40/100% ED): 22/15 Nm

Hydraulic unit

- oil tank capacity: approx. 25 l

- pump power: 1.1 kW

- maximum operating pressure: 80 bar

Cooling unit

- coolant tank capacity: 200 l

- pump power: 1.65 kW

- flow rate at 6 bar: 50 l/min

Dimensions and weight

- length with chip conveyor: 4770 mm

- width with control cabinet: 2220 mm

- height with control cabinet: 1950 mm

- weight of machine: approx. 6500 kg

Equipment of the MF TWIN 65Y CNC lathe

- CNC controller: SIEMENS SINUMERIK 840 C

- bar feeder: IRCO SiMag

- upper tool head with Y axis

- lower tool head

- sub-spindle

- 3-jaw hydraulic chuck: BISON (2 pcs)

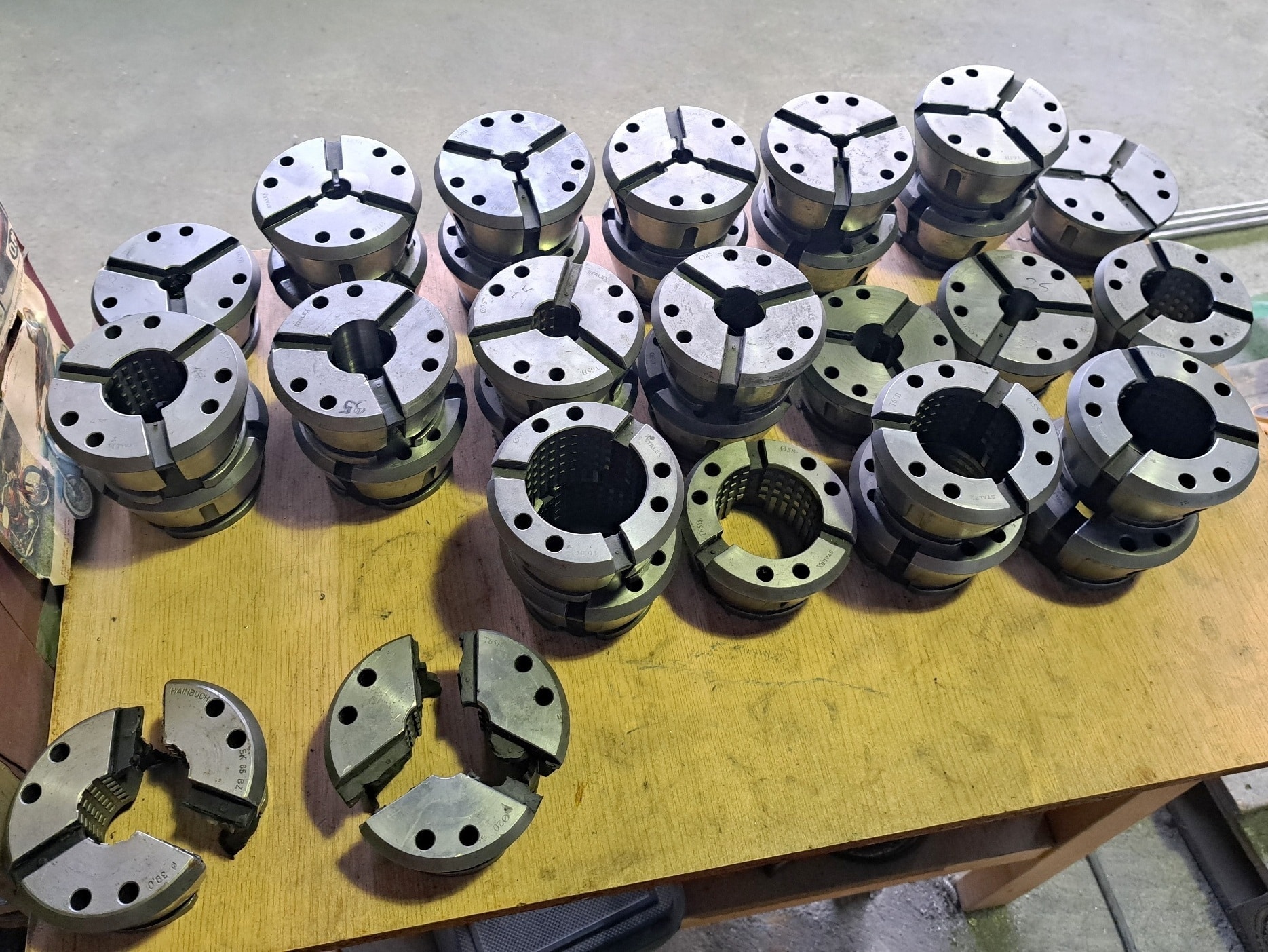

- hydraulic sleeve chuck: HAINBUCH (2 pcs)

- driven tools

- sleeves for sleeve chuck with diameter:

- gripper for picking up the finished workpiece

- straight toolholders (3 pcs)

- 90° driven angle toolholders (2 pcs)

- knives toolholders (9 pcs)

- drill/boring toolholders (5 pcs)

- workpiece conveyor

- chip conveyor

- coolant filtration system: KNOLL

– 6, 18, 28, 29, 30, 34, 45, 50, 52, 58 mm (1 pc.)

– 8, 10, 12, 15, 16, 25, 35, 40, 55, 60 mm (2 pcs.)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe