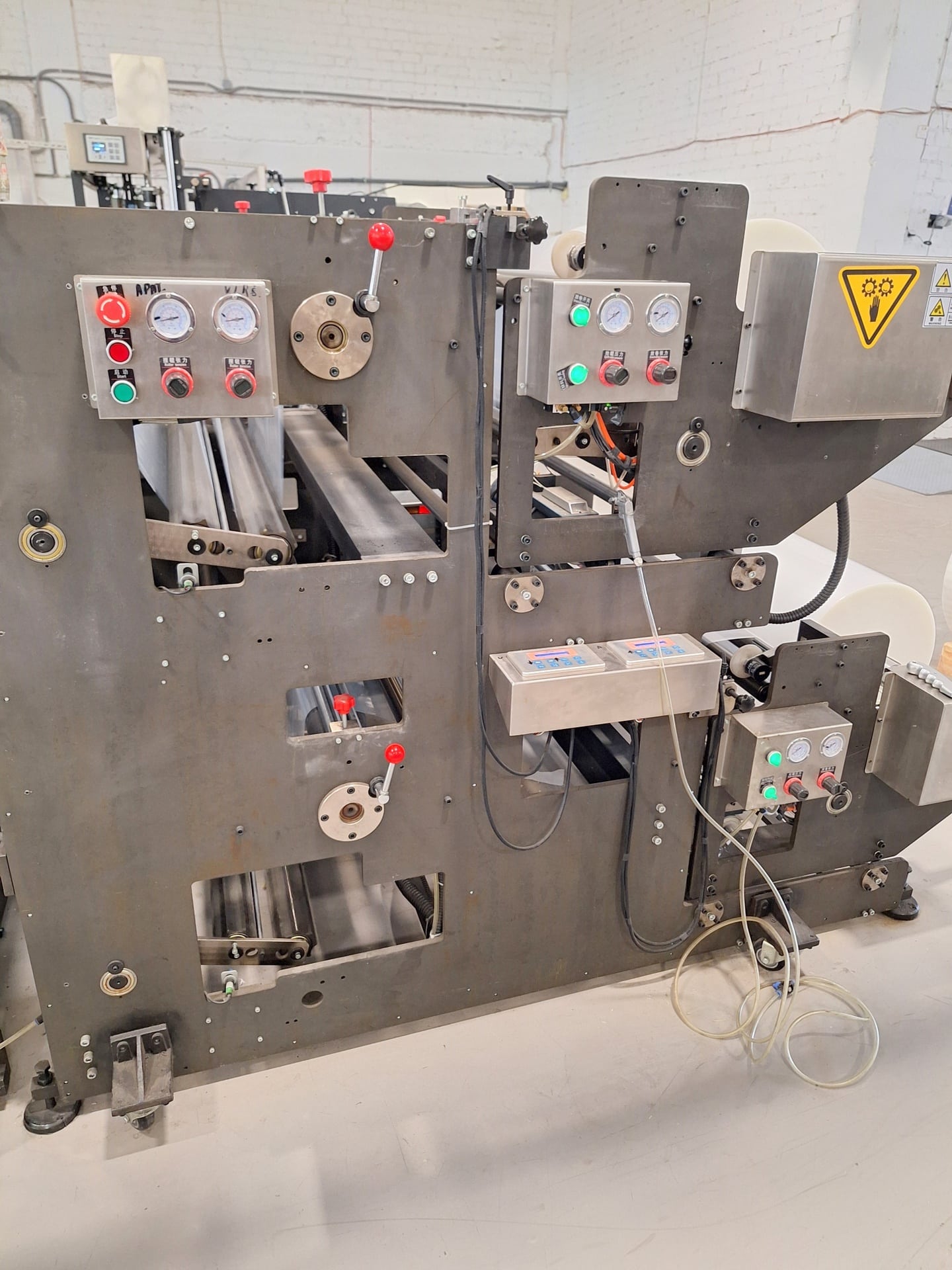

GSD-1200S wicket bag making machine was built in 2020 in China by Wuxi Hongchang Precision Machinery Co., Ltd. This highly efficient and precise machine is designed for the fully automatic, mass production of film bags with side and bottom sealing. The material, with a maximum thickness of 1.5 mm, is unwound from the rolls by two YASKAWA inverter-controlled unwinders into the workspace, where it is then accurately measured, cut and sealed. Once the production process is complete, the finished bags are transferred to a work table, where they are stacked on top of each other to form small packages. The GSD-1200 S plastic bag and sack production line is also equipped with world-class brand components which achieve high quality products with minimal effort. The total weight of the machine is 9000 kg.

The GSD 1200 S film bag making machine is fully complete and consists of the following components:

– PLC control: PANASONIC

– bottom and longitudinal sealer

– vertical sealing unit: SEW asynchronous motor

– unwinding unit: horizontal shaft, tension control system with powder brake

– feeding mechanism: MITSUBISHI 5 kW AC servo motor (2 pcs.)

– cutting knife

– trim rewinder

– YASKAWA inverter

– WEINVIEW control panel

– photocells (KT5, KOTEC)

– YANXIN powder brake

– cooling unit

– AIR TAC pneumatic unit

– OMRON encoder

– solenoid valve

– synchronizing belt

– NSK main bearing

– thermocouple

– mechanical rheostat

Technical specifications of the GSD-1200S wicket bag making machine

- type of packaging: plastic bags with side and bottom sealing

- type of material: all kinds of laminated films

- maximum size of film bag (L x W): 400 x 1200 mm

- minimum size of film bag (L x W): 400 x 300 mm

- material thickness: 0,05-1,5 mm

- maximum material roll width (top unwind): 1200 mm

- maximum material roll diameter (top unwinder): 800 mm

- maximum material roll width (bottom unwinder): 1200 mm

- maximum material roll diameter (bottom unwinder): 800 mm

- unwinder operating speed: 36 m/min

- working speed: 100 cuts/min

- installed power: 70 kW

- power supply: 380 V; 50 Hz

- dimensions (L x W x H): 9000 x 2000 x 2000 mm

- weight of machine: 9000 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe