GWELL GWC 80-156 WPC production line manufactured in 2015 is characterised by high production efficiency. WPC boards are made by combining natural components with thermoplastic polymers. This results in a material with the high aesthetics of wood and the exceptional durability of plastics, distinguished by full resistance to fungus, insects and various atmospheric factors.

The production line consists of:

– GWC 80/156 twin-screw extruder

– GWC 65/132 twin-screw extruder

– CUT 240 saw

– CAL 14000/6 calibrating table

– ROL 240 2-caterpillar haul-off

– unloading table

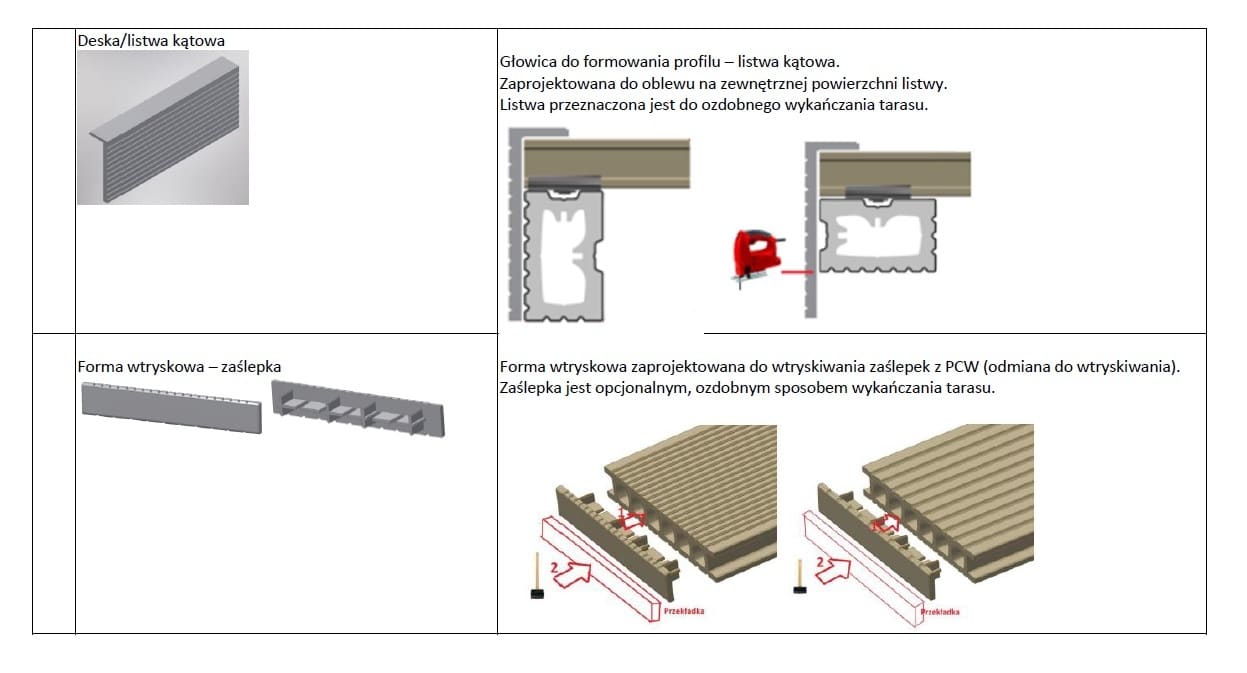

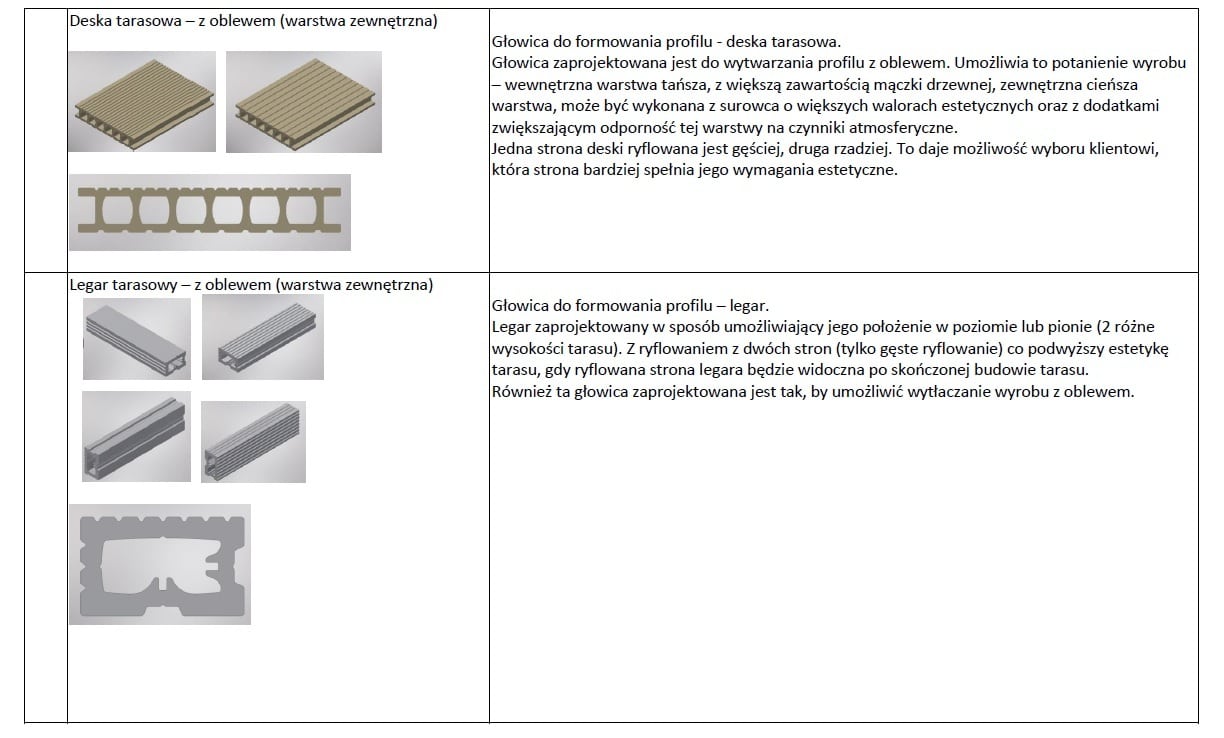

The WPC profile extrusion line is offered with optional heads for forming different types of profiles from these products. To date, the machine has only been in operation for a dozen days and has not been used at full production scale.

For an additional charge, equipment cooperating with the line can be purchased:

– GWELL 500/1000L mixer (69.050 € net)

– pulveriser (complete pulverising line + dryer, 14.290 € net)

– brushing machine (21.430 € net)

– grinding machine (13.100 € net)

Thanks to the additional equipment, the produced profile goes straight to the brushing machine and grinding machine, where its surface is scraped off to give the element a more rustic appearance.

Technical specifications of individual components of the GWELL GWC 80-156 extrusion line

GWC 80/156 twin-screw extruder

- capacity: 120-400 kg/h

- maximum extrusion pressure: 450 Pa

- extrusion axis height: 1000 mm

- screw length: 1820 mm

- screw diameter at take-up: 156 mm

- screw diameter at exit: 80 mm

- screws rotational speed: 5-37 rpm

- main motor power: 55 kW

- main motor rotational speed: 1480 rpm

- number of cylinder heating zones: 5

- cylinder heating system power: 36 kW

- number of head heating zones: 8+1

- installed power: 100 kW

- power supply: 3x 400 V; 50 Hz

- dimensions (L x W x H): 3700 x 900 x 1800 mm

- weight of machine: 4500 kg

GWC 65/132 twin-screw extruder

- capacity: 80-250 kg/h

- maximum extrusion pressure: 450 Pa

- extrusion axis height: 1000 mm

- screw length: 1440 mm

- screw diameter at take-up: 132 mm

- screw diameter at exit: 65 mm

- screws rotational speed: 5-37 rpm

- main motor power: 37 kW

- main motor rotational speed: 1480 rpm

- number of cylinder heating zones: 4

- cylinder heating system power: 18.5 kW

- number of head heating zones: 6+1

- installed power: 58.5 kW

- power supply: 3x 400 V; 50 Hz

- dimensions (L x W x H): 3300 x 900 x 1800 mm

- weight of machine: 3700 kg

CUT 240 saw

- maximum cutting width: 240 mm

- installed power: 2.2 kW

- power supply: 3x 400 V; 50 Hz

- weight of machine: 1600 kg

Mixing unit GWELL 500/1000L

- maximum mixing capacity: 600 kg/h

- warm mixer capacity: 500 l

- cold mixer capacity: 1000 l

- rotational speed of warm mixer propeller: 430/860

- rotational speed of cold mixer propeller: 60

- installed power: 70 kW

- warm mixer motor power: 55 kW

- cold mixer motor power: 15 kW

- power supply: 3x 400 V; 50 Hz

- dimensions (L x W x H): 5300 x 2700 x 2870 mm

- weight of machine: 4700 kg

CAL 14000/6 calibrating table

- working area (L x W): 12000 x 600 mm

- extrusion axis height: 1000 mm

- height adjustment: electric

- approach: electrical

- lateral movement: manual

- number of vacuum pumps: 4x 5.5 kW

- number of vacuum connections: 50

- number of water pumps: 2x 4 kW

- number of water connections: 30

- installed power: 38 kW

- power supply: 3x 400 V; 50 Hz

- dimensions (L x W): 14000 x 1200 mm

- weight of machine: 4000 kg

Unloading table

- table drive: pneumatic, 0.6 MPa

- machine dimensions (L x W): 6000 x 600 mm

ROL 240 2-caterpillar haul-off

- caterpillar dimensions (L x W): 2000 x 235 mm

- extraction speed: 1.3 m/min

- pulling force: 30000 N

- extrusion axis height: 1000 mm

- installed power: 2.2 kW

- power supply: 3x 400 V; 50 Hz

- dimensions (L x W): 3000 x 1200 mm

- weight of device: 2800 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe