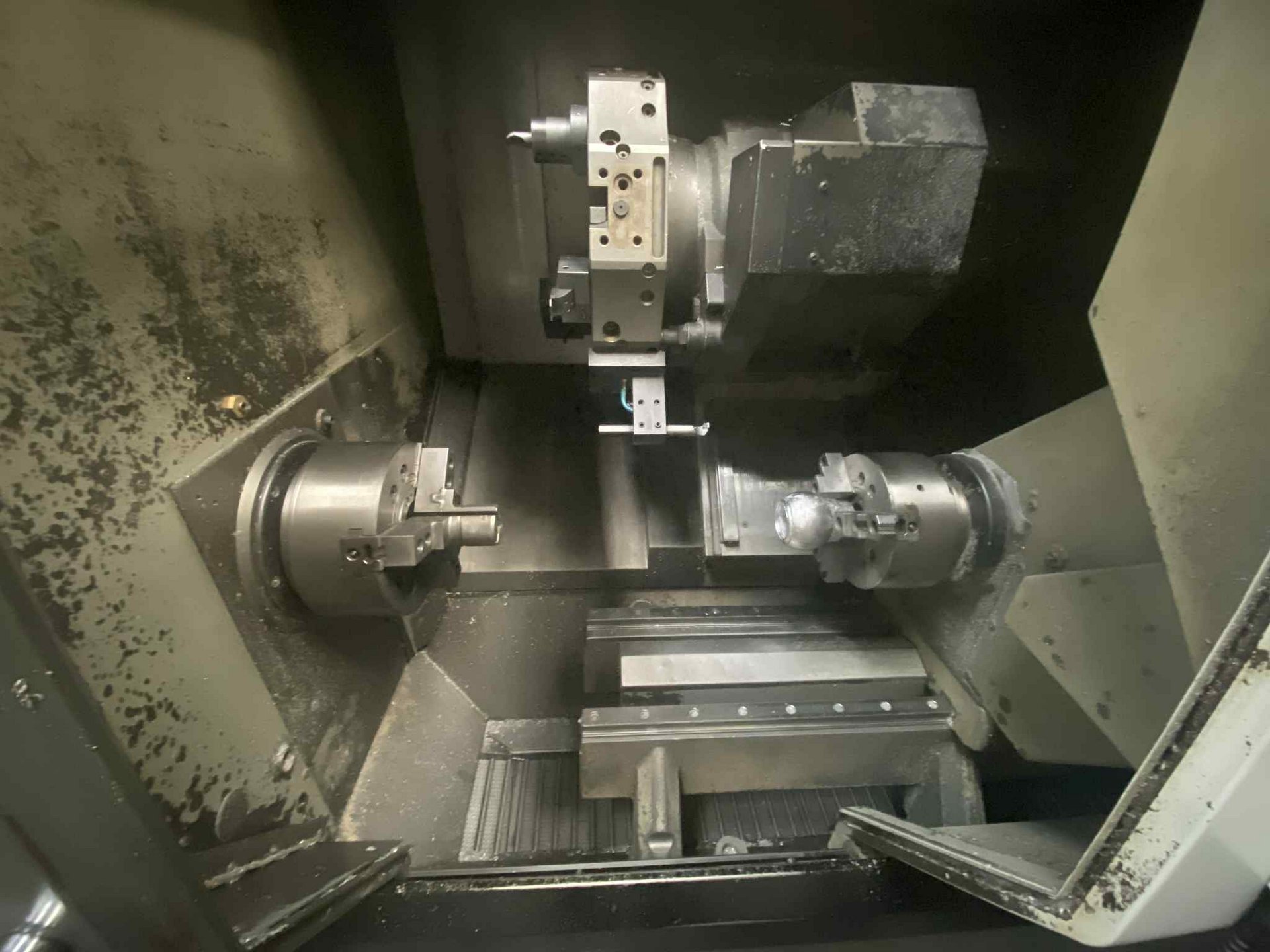

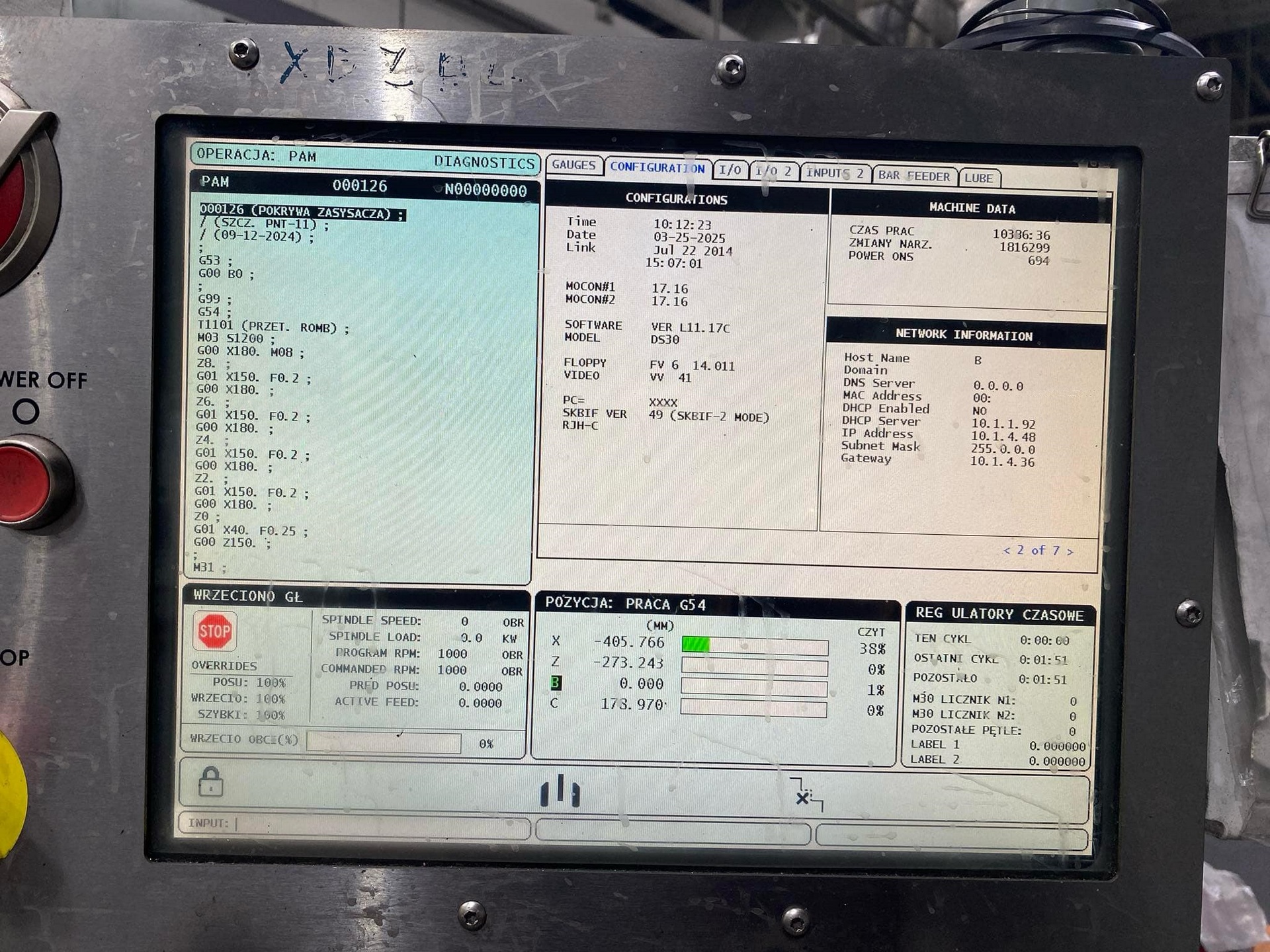

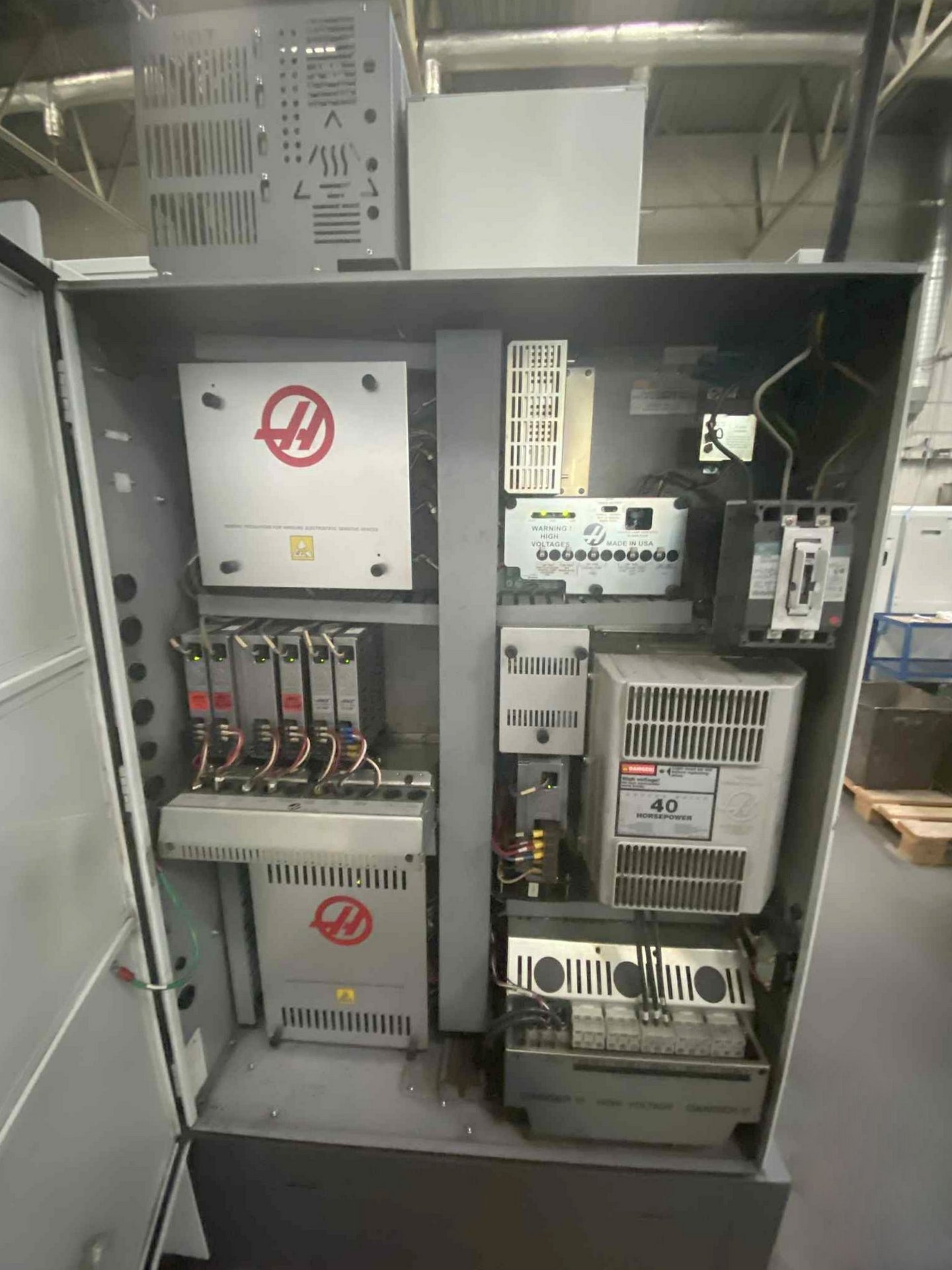

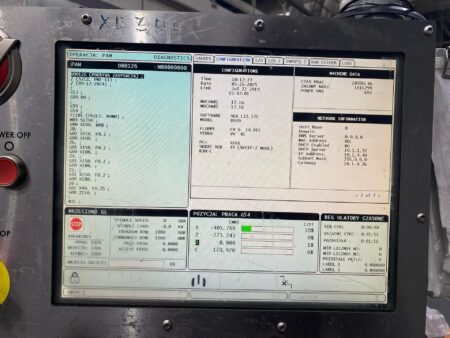

HAAS DS-30 CNC lathe was built in 2013 in the United States by HAAS AUTOMATION, INC. The machine, designed for machining workpieces with a maximum diameter of 457 mm, offers excellent efficiency, reliability and precision. Inside a large workspace there are two spindles with a C-axis, which enable the machining of both sides of a workpiece in a single work cycle. The tool head, in turn, allows for the attachment of both fixed and driven tools. This solution increases the flexibility of the machine by enabling it to be adapted to specific production needs. All this is complemented by advanced CNC control with many useful functions. The HAAS DS30 CNC turning center weighs 7221 kg.

Technical specifications of the HAAS DS-30 metal lathe

- maximum turning diameter: 457 mm

- maximum turning length: 660 mm

- swing over bed: 806 mm

- swing over cross slide: 527 mm

- feed in the X/Z axis: 318/660 mm

- rapid traverse in the X, Z axis: 24 m/min

- number of driven tools: 6

- shank cross-section: 25×25 mm

- tool change time: 1 s

- compressed air requirement: 113 l/min

- compressed air pressure: 6.9 bar

- coolant tank capacity: 208 l

- power supply: 3x 360-480 V; 50/60 Hz

- weight of the HAAS DS 30 machine: 7221 kg

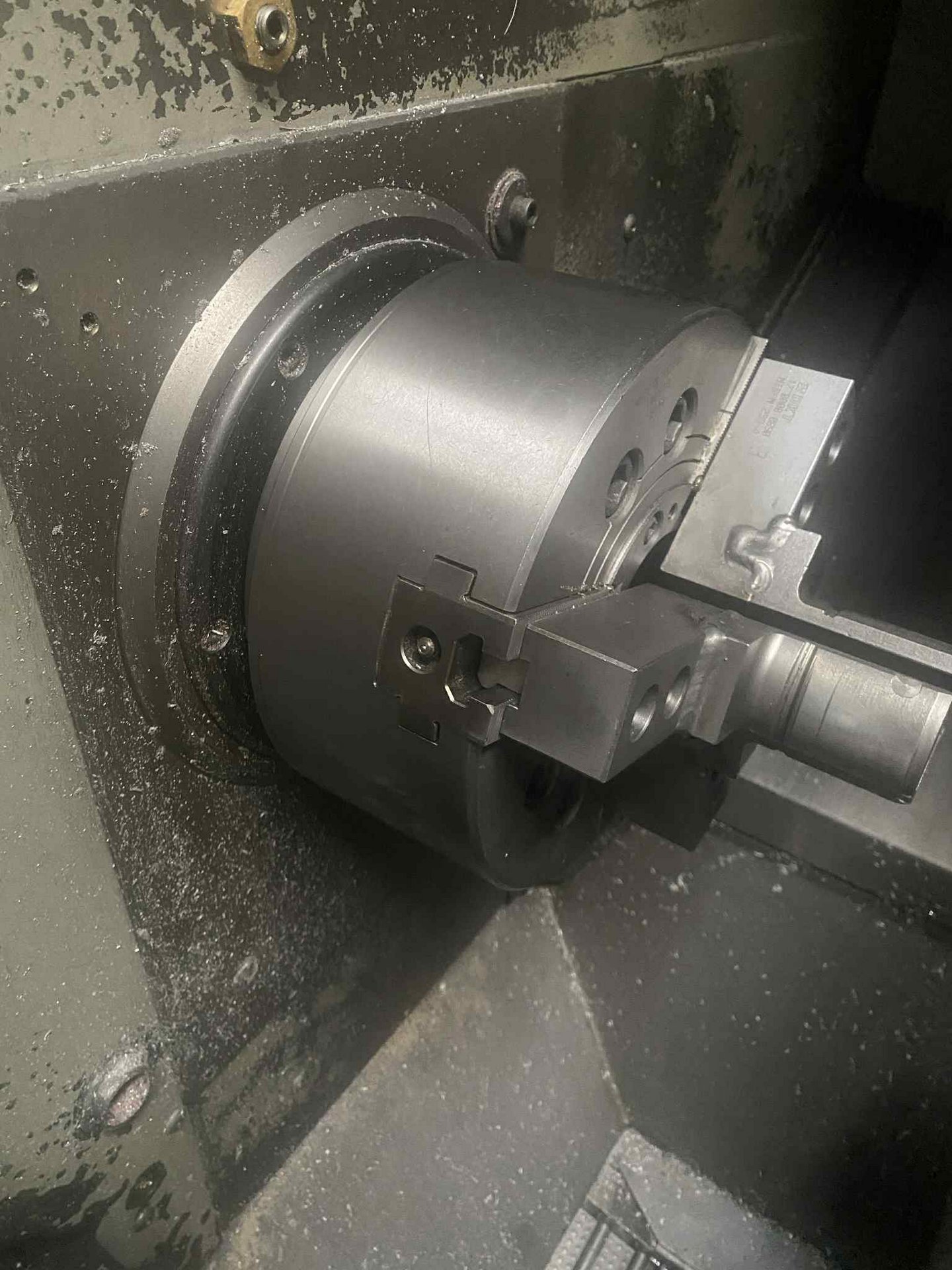

Main spindle

- maximum rotational speed: 4000 rpm

- maximum torque (at 500 rpm): 407 Nm

- drive power: 22 kW

- bore diameter: 76 mm

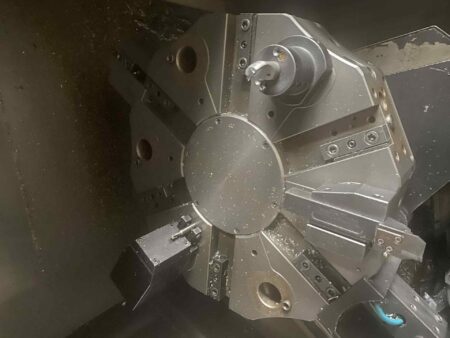

- chuck diameter: 254 mm

- spindle end: A2-6

- C axis

- C axis indexing: 0.01°

Sub-spindle

- maximum rotational speed: 4000 rpm

- maximum torque (at 700 rpm): 183 Nm

- drive power: 14.9 kW

- bore diameter: 61.9 mm

- chuck diameter: 210 mm

- spindle end: A2-5

- C axis

- C axis indexing: 0.01°

Equipment of the HAAS lathe

- CNC control: HAAS

- sub-spindle

- C axis

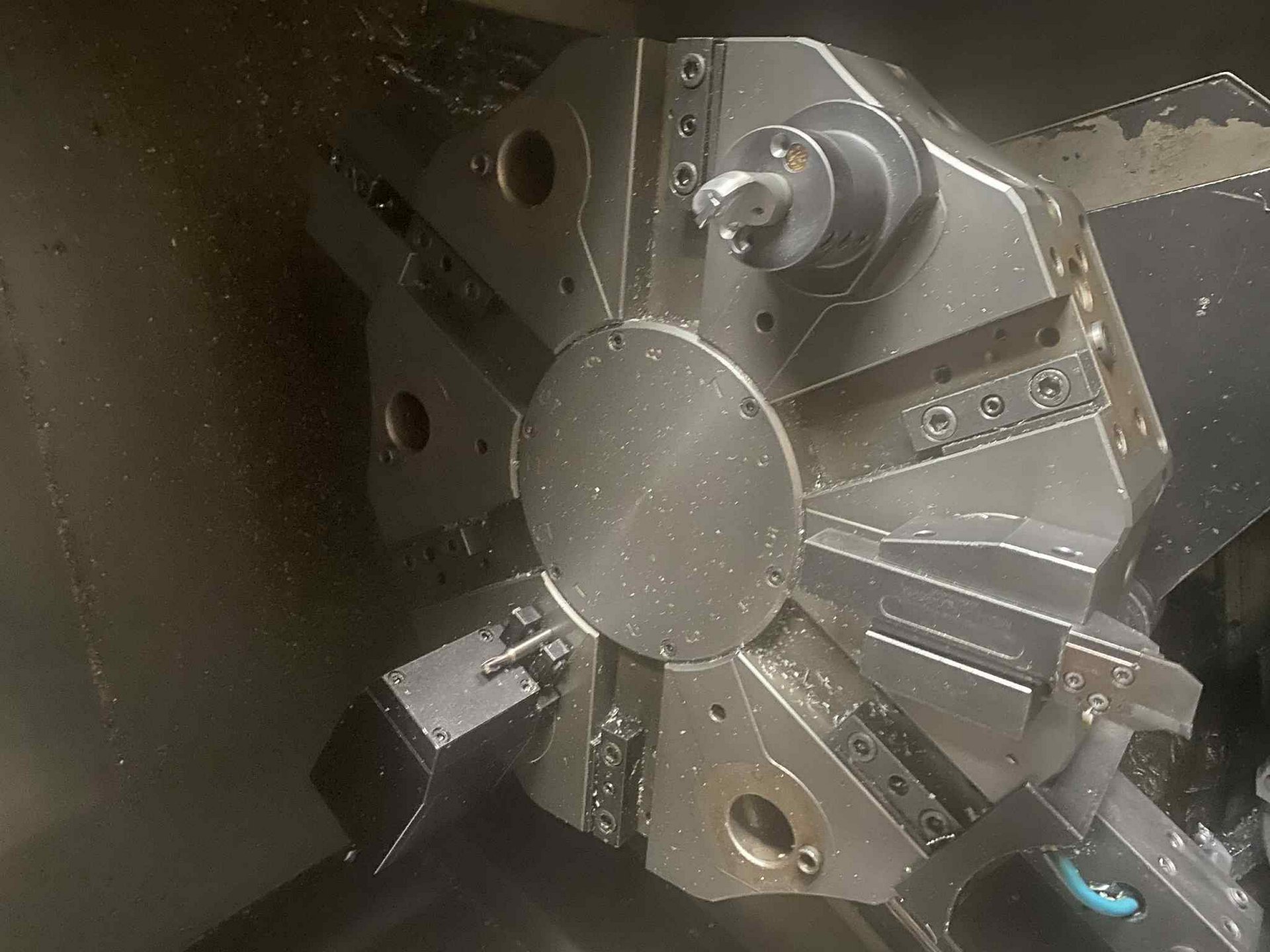

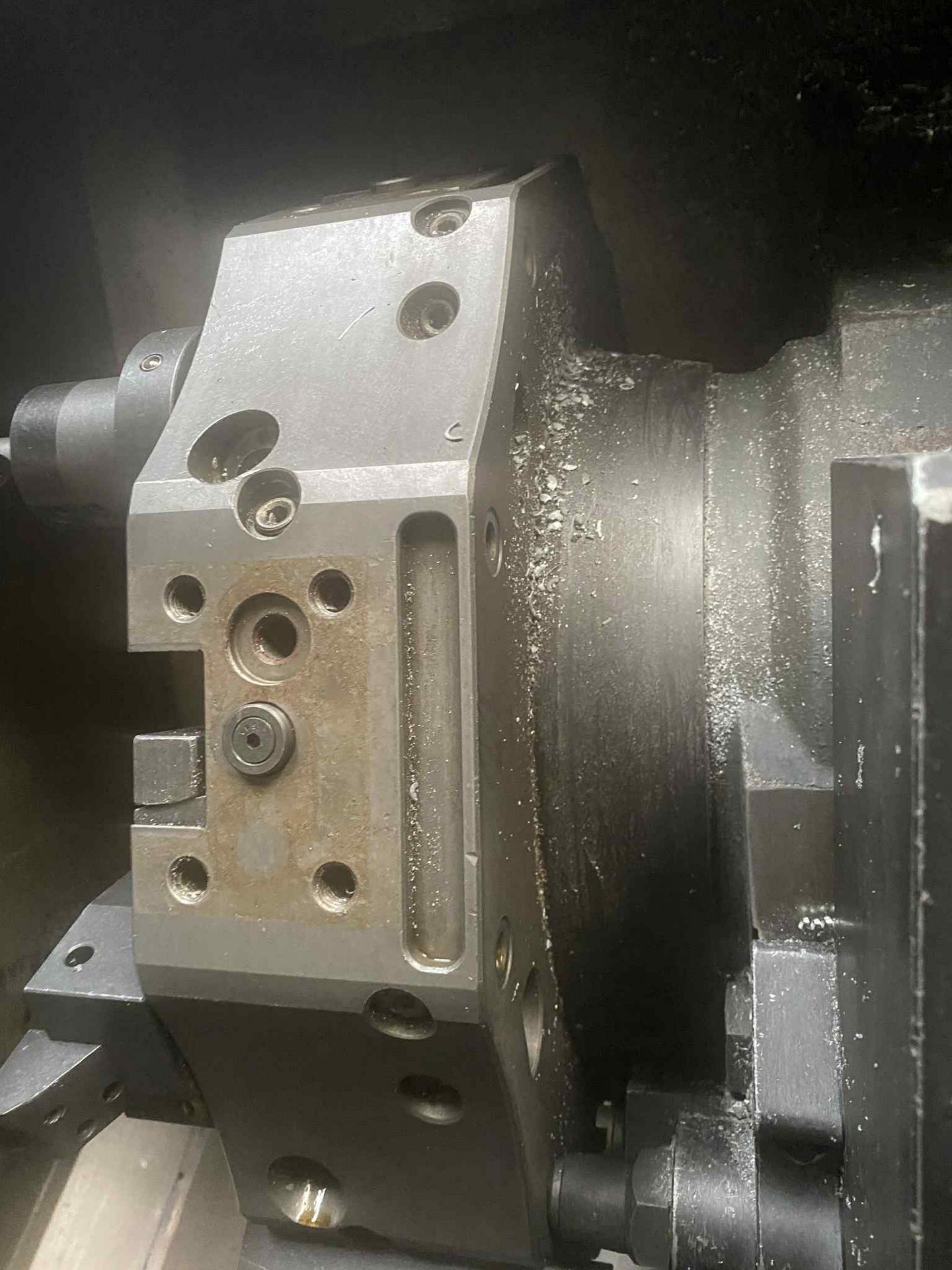

- 12-position turret BOT/VDI

- driven tools

- BOT20M DS toolholders

- hydraulic 3-jaw chuck with soft jaws

- tool holder for radial and axial driven tools

- belt chip conveyor

- electronic knob

- threading without compensation holder

- ballscrews temperature compensation

- installation for compressed air connection

- automatic central lubrication system

- cooling system with pull-out coolant tank

- workspace illumination

(The technical parameters given were obtained from the machine manufacturer’s website. Their accuracy cannot be guaranteed and they may therefore differ slightly from reality.)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe