HAAS ST-15 CNC turning center manufactured in the USA in 2019, is used for precision machining of metal workpieces with a maximum diameter of 173 mm. Thanks to its small size and emphasis on high productivity, rigidity and thermal stability, the ST-15-NGC CNC lathe is ideal for both small workshops and intensive production work.

The machine comes with modern technology and extensive equipment, allowing it to exploit all its strengths for extremely precise turning of workpieces. Inside the illuminated work area there is, among others, a hydraulic three-jaw chuck, a twelve-position VDI40 tool magazine and a very efficient spindle rotating with a maximum speed of 4000 rpm.

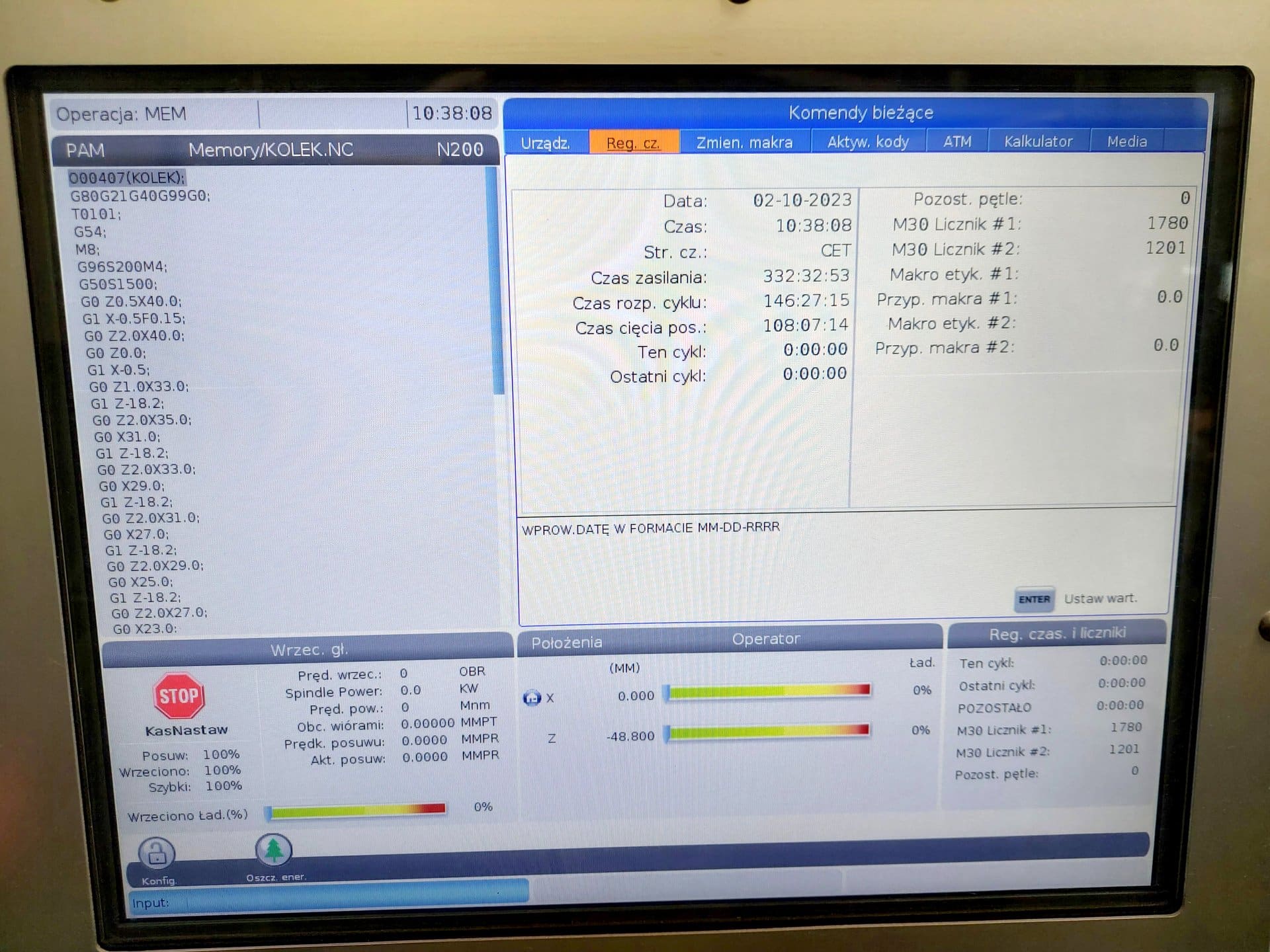

The HAAS ST 15 turning centre is offered with extensive additional equipment, including a tailstock with hydraulic quill extension, an automatic tool probe and a state-of-the-art HAAS NGC CNC controller located on the arm. The machine is new and has never been used – it has not worked a single hour. The total weight of the lathe is 3584 kg.

Technical data of the HAAS ST-15 CNC lathe

- maximum turning diameter: 173 mm

- passage diameter over the bed: 686 mm

- passage diameter over tailstock bed: 686 mm

- passage diameter over cross slide: 406 mm

- cross slide feed in X axis: 200 mm

- Z-axis longitudinal slide feed: 406 mm

- rapid feed rate in X,Z axis: 30.5 m/min

- maximum pulling force of drives in X,Z axis: 14.7 kN

- maximum spindle speed: 4000 rpm

- spindle power: 14.9 kW

- maximum spindle passage: 63.5 mm

- maximum spindle torque (at 500 rpm): 203 Nm

- longitudinal travel of tailstock: 100 mm

- three-jaw chuck diameter: 210 mm

- positioning accuracy: ± 0.005 mm

- positioning repeatability: ± 0.003 mm

- capacity of coolant tank: 114 l

- compressed air consumption: 113 l/min

- compressed air pressure: 6.9 bar

- dimensions (L x W x H): 3210 x 1780 x 2060 mm

- ST-15 machine weight: 3584 kg

Equipment of the HAAS ST 15 lathe

- CNC controller: HAAS NGC

- automatic tool probe

- tool head: VDI40 (12 positions)

- spindle tip: A2-6

- tailstock with hydraulic quill extension

- tailstock taper: MT3

- hydraulic three-jaw chuck with soft jaws

- SafeRun collision mitigation system

- EPFDM power supply failure early detection module

- belt chip conveyor

- finished parts collection system

- temperature compensation of the X axis leadscrew

- automatic central lubrication system

- cooling system with integrated coolant tank

- workspace illumination

- measuring arm

- complete set of accessories

- operating and programming instructions

- DTR – technical and propulsion documentation

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe