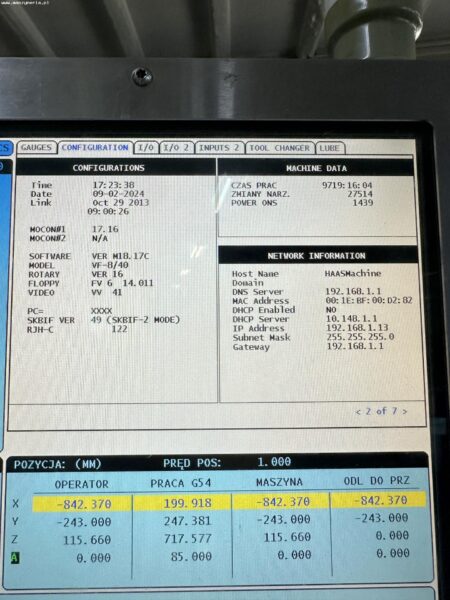

HAAS VF-8/50 CNC machining center was built in 2014 by the renowned American brand HAAS AUTOMATION INC. The machine, which is designed for machining heavy and hard materials, stands out for its high precision, efficiency and reliability, making it simple to meet any production requirements. The machining process is performed inside a large working area which includes, among others, a two-stage spindle, a capacious magazine with automatic tool changer and a large work table with a length of 1626 mm and a width of 914 mm. The HAAS VF 8 CNC vertical machining center is offered with RENISHAW measuring probes and advanced numerical control. During its entire service life, the machine has worked for a total of 9719 hours. The HAAS CNC milling machine weighs 13155 kg.

Technical parameters of the HAAS VF-8/50 milling center

- CNC controller: HAAS

- feed in the X/Y/Z axis: 1626/1016/762 mm

- rapid traverse in X,Y,Z axis: 15.2 m/min

- maximum workpiece weight: 1814 kg

- work table dimensions (L x W): 1626 x 914 mm

- maximum spindle rotational speed: 7500 rpm

- spindle taper: CT or BT 50

- maximum spindle torque (at 700 rpm): 460 Nm

- spindle drive power: 22.4 kW

- spindle drive type: 2-speed gearbox

- spindle bearing lubrication: air/oil injection

- tool magazine capacity: 30+1

- automatic tool changer type SMTC

- maximum tool diameter (adjacent socket occupied/adjacent socket empty): 102/254 mm

- maximum tool length (from riveting line): 406 mm

- maximum tool weight: 13.6 kg

- average tool change time: 4,2 s

- average tool change time chip-to-chip: 6.3 s

- tool measuring probe: RENISHAW

- workpiece measuring probe: RENISHAW

- operating hours: 9719 h

- T-slot number: 7

- T-slot width: 15.9-16 mm

- T-slot spacing: 125 mm

- coolant tank capacity: 360 l

- minimum air pressure: 5.5 bar

- air consumption (at 6.9 bar): 113 l/min

- power supply: 3x 360-480 V; 50/60 Hz

- weight of the HAAS VF-8/50 machine: 13155 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe