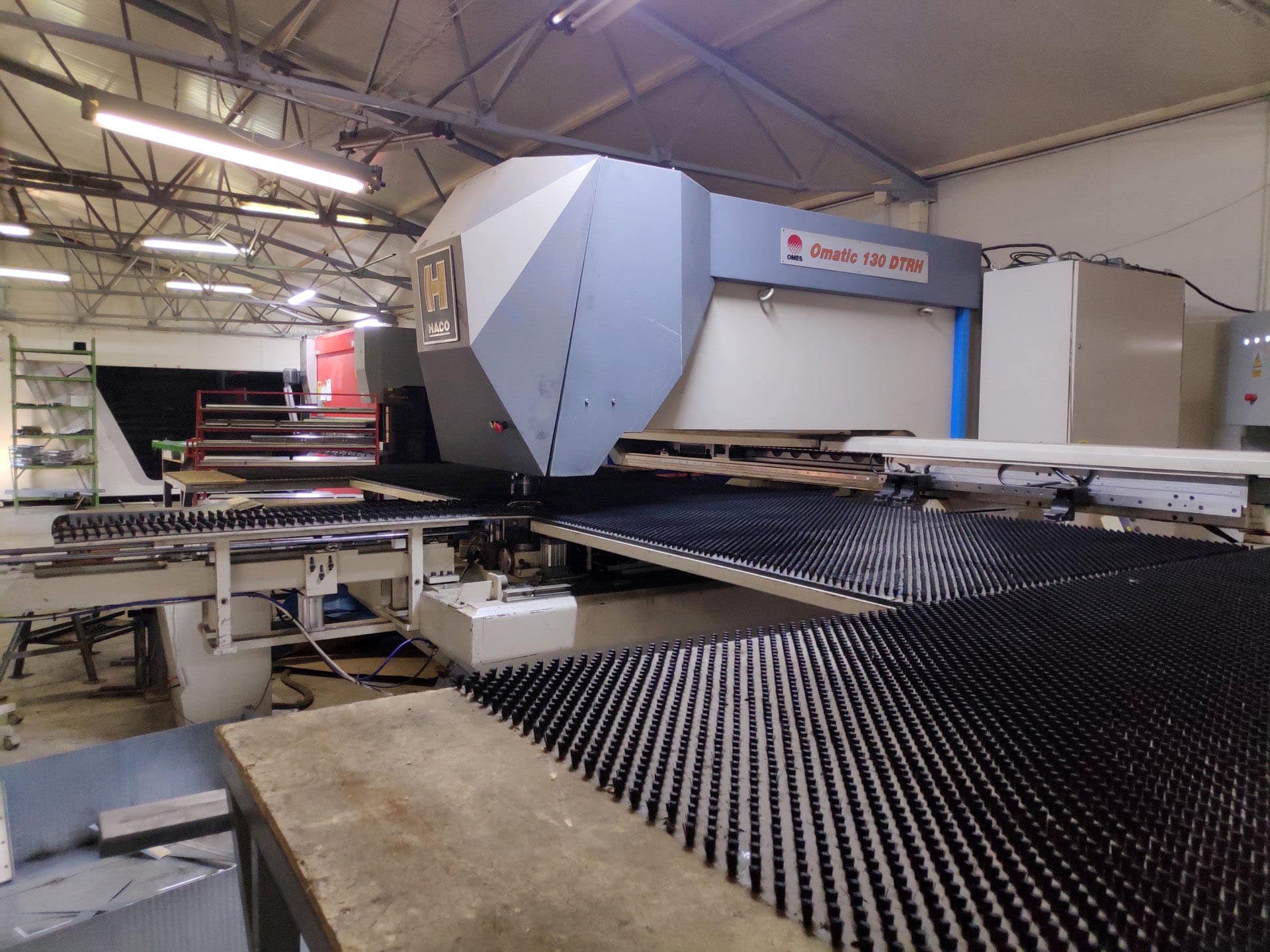

HACO OMATIC 130 DTRH punching machine was built in 2014 in Belgium. The machine is used to punch various size shapes and holes in workpieces weighing up to 150 kg and having a maximum thickness of 6.5, a width of 1500 mm and a length of 4000 mm. The machine operator manually operates the punching machine by loading the workpiece on the working table and changing the punching tools using a special device offered in the price of the machine.

The punching process takes place on the brush table of the punching machine, which significantly reduces noise levels and adequately protects the sheet metal surfaces against various types of scratches and nicks. Depending on the selected mode, the machine performs between 1,000 and 1,500 punches per minute with a press force of 30 tonnes. The equipment includes amongst others a TPC 69C Graphics CNC controller for graphical programming of the desired shapes, a set of punching tools and three hydraulic sheet metal presses. The total weight of the punching machine is 8700 kg.

Technical data of the HACO OMATIC 130 DTRH punching machine

- press force: 30 t

- maximum workpiece weight: 150 kg

- maximum workpiece length: 4000 mm

- maximum workpiece width: 1500 mm

- maximum workpiece thickness: 6.5 mm

- feed rates in the X/Y/Z axis: 2010/1510/37 mm

- rapid feed rates in the X/Y axis: 64 m/min

- positioning accuracy in the X/Y/Z axis: +/- 0.05 mm

- programming accuracy in the X/Y/Z axis: 0.01 mm

- impact speed marking mode: 1500 1/min

- impact speed nibbling mode: 1000 1/min

- maximum tool diameter: 70 mm

- total power requirement: 25 kW

- compressed air pressure: 6 bar

- power supply: 380 V; 50 Hz

- dimensions (L x W x H): 3400 x 3200 x 2500 mm

- weight of the OMATIC 130 DTRH machine: 8700 kg

Equipment of the punching machine

- CNC control: TPC 69C Graphics

- brush table

- hydraulic sheet clamps: 3 pcs.

- set of punching tools

- manual device for changing punching tools in the machine

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe