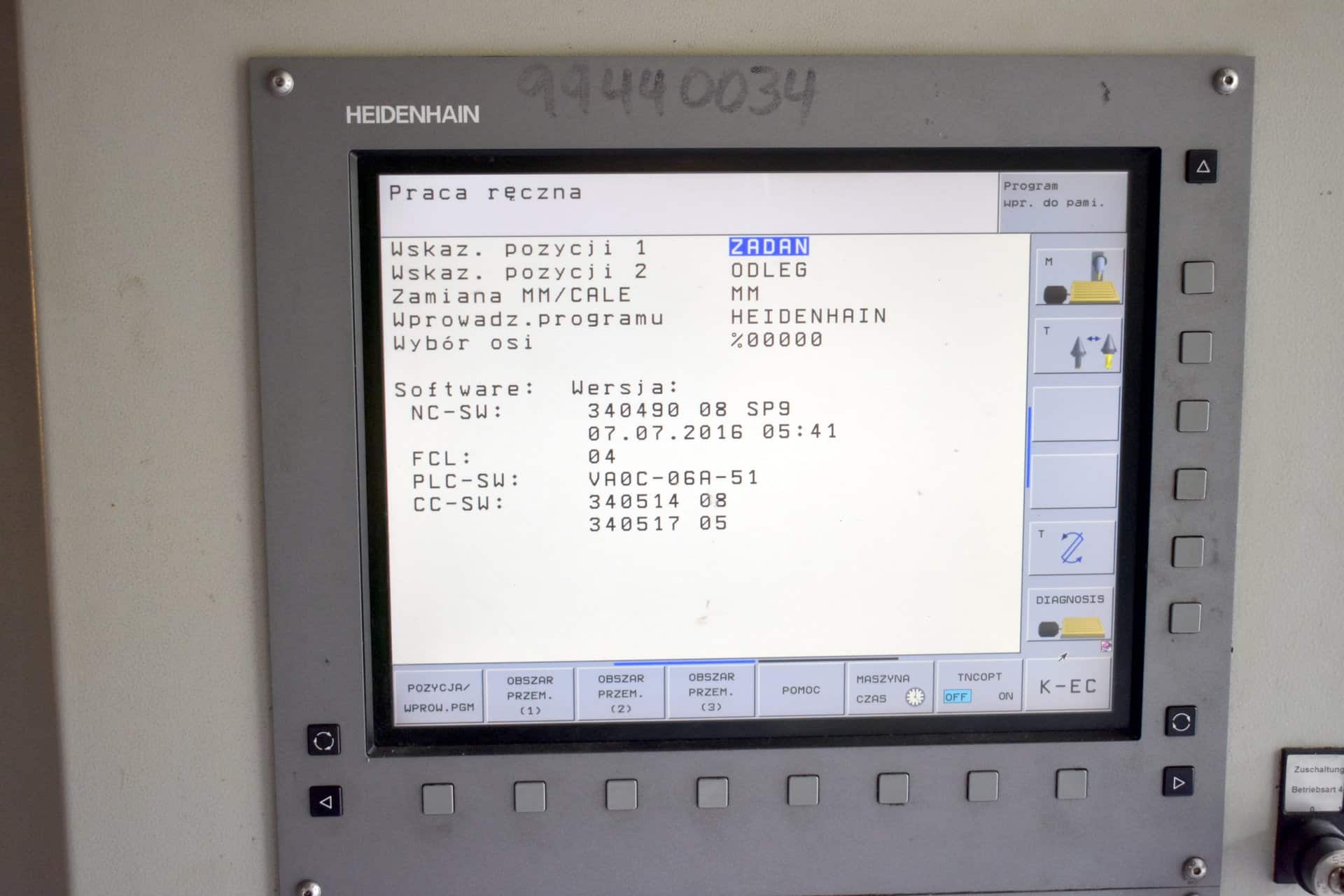

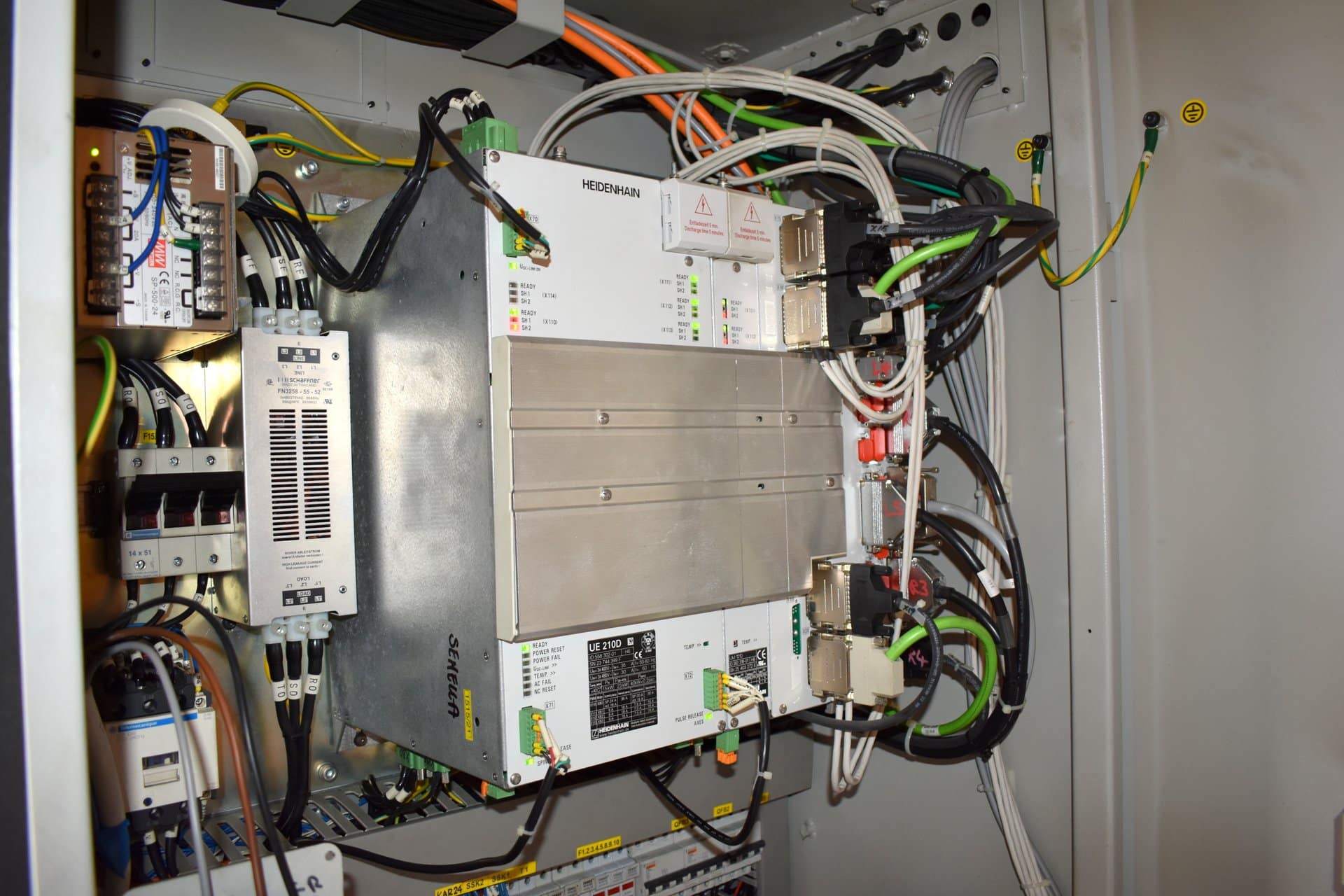

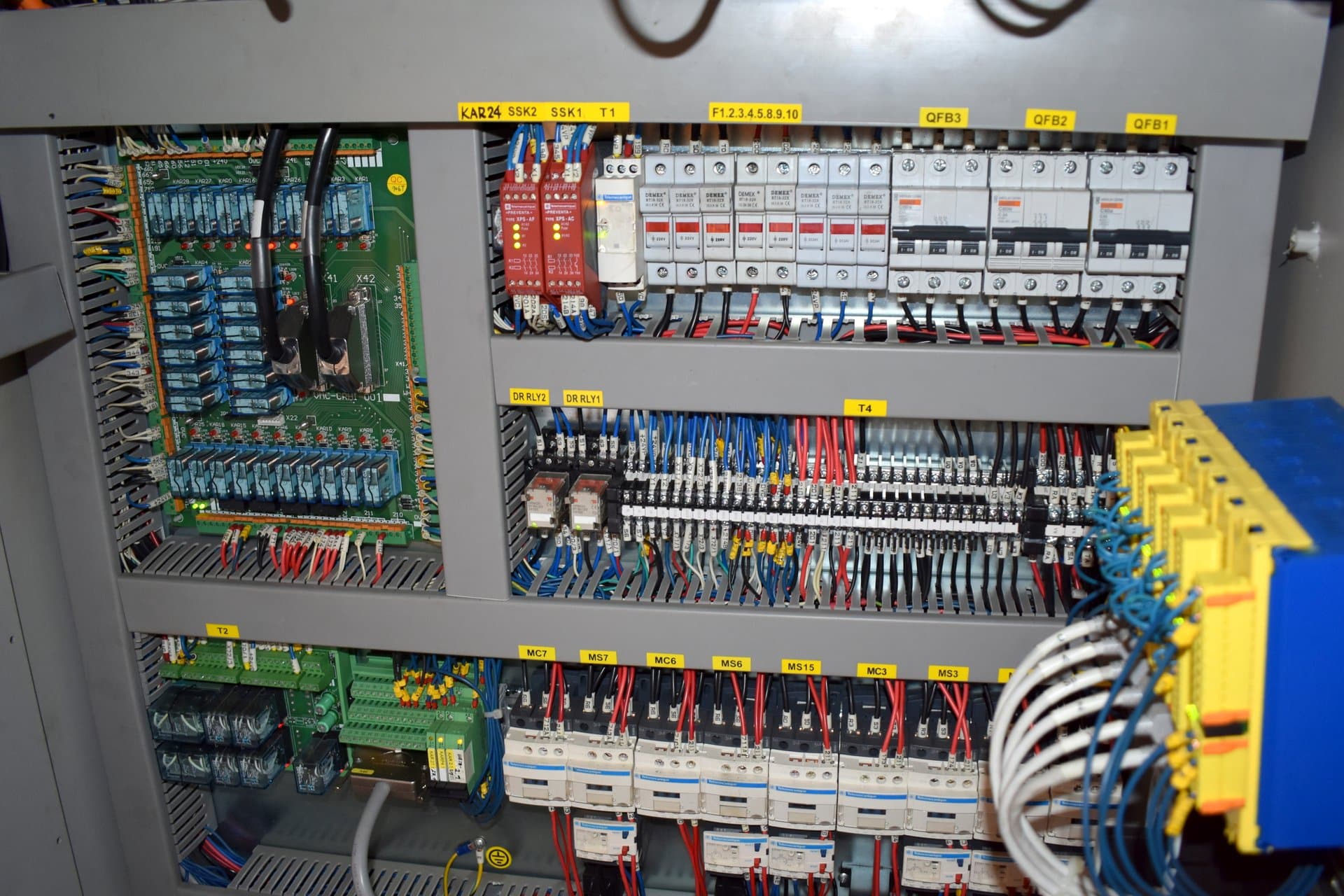

HARDINGE GX-1000 CNC machining centre was manufactured in 2008 in Taiwan. The extremely reliable machine performs precision machining of workpieces in the X,Y,Z axes with feeds of 1020 mm (X axis), 540 mm (Y axis) and 540 mm (Z axis), and also supports the fourth and fifth axis. Full control of the milling machine operation and programming of the machining processes is made possible by the intuitive HEIDENHAIN iTNC 530 CNC controller with operator panel, located on the machine body.

The UNITECH HARDINGE GX 1000 CNC milling machine also has a very powerful spindle rotating at 10000 rpm, which significantly reduces machining time and guarantees high quality and precision. The milling centre is offered with accessories including: 24 position tool magazine, changing tools in a very short time, and HEIDENHAIN TS 640 workpiece probe. The total weight of the machining centre is 5900 kg.

Technical specifications of the HARDINGE GX-1000 CNC vertical machining centre

- feed rates in the X/Y/Z axis: 1020/540/540 mm

- worktable surface (L x W): 1120 x 540 mm

- maximum spindle speed: 10000 rpm

- spindle motor power: 20 HP (15 kW)

- tool magazine capacity: 24 pcs.

- support of 4+5 axes

- total power requirement: 21 kW

- total weight of GX 1000 machine: 5900 kg

Equipment of the CNC milling centre

- CNC controller: HEIDENHAIN iTNC 530

- workpiece probe: HEIDENHAIN TS 640

- spindle taper: SK40

- cooling via spindle

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe