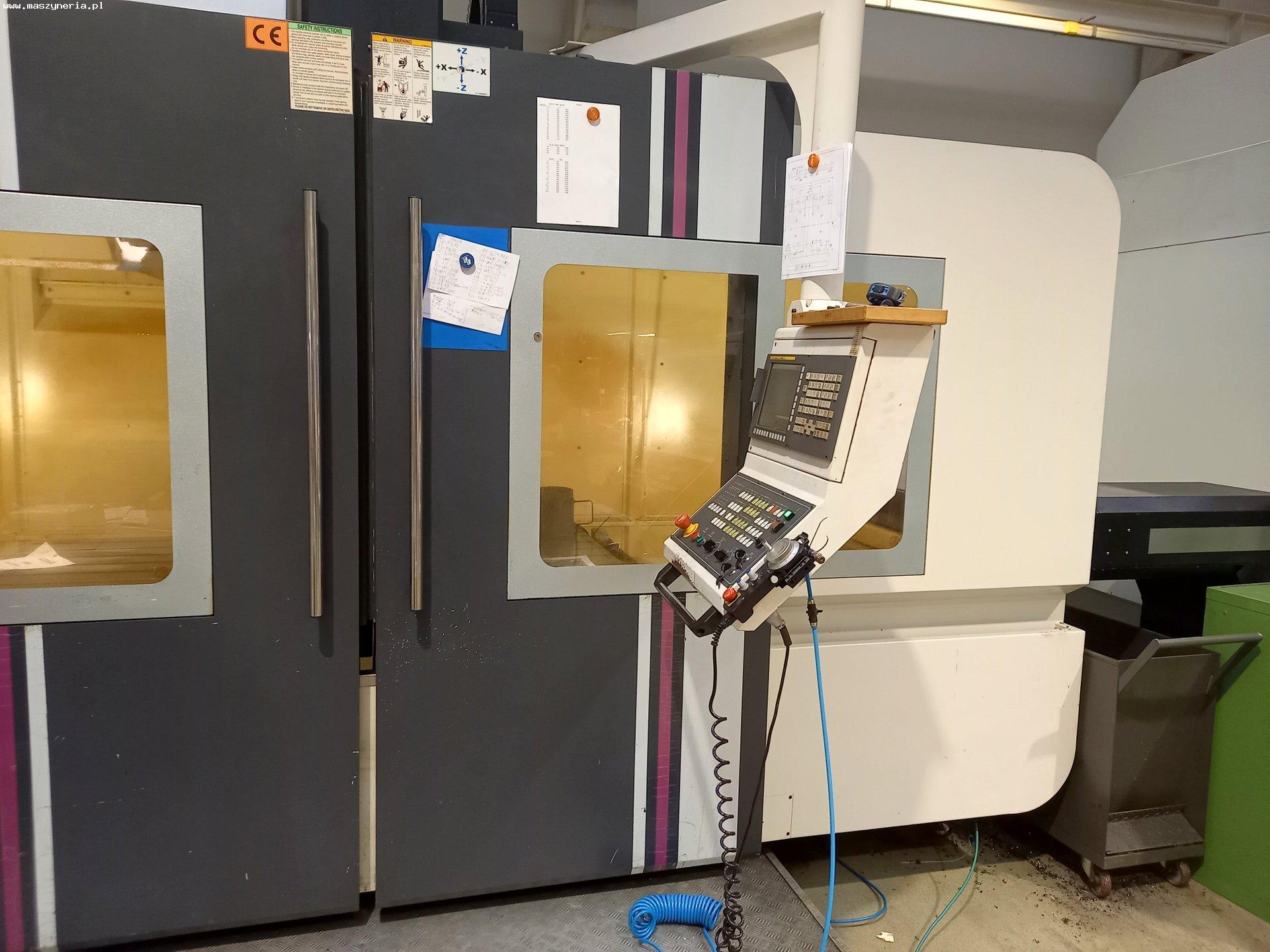

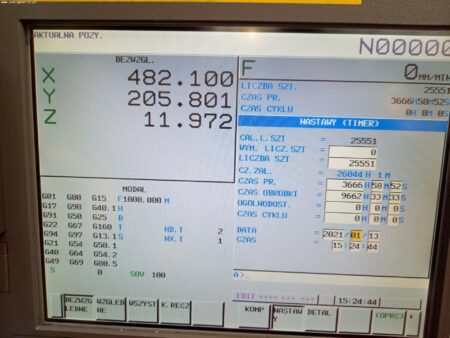

The HARTFORD HCMC-1892 CNC machining center was built in 2013 by the Taiwanese company Hartford Machinery. The machine works in three axes (X, Y, Z) with maximum axis travels of 1800 mm, 920 mm and 700 mm, respectively. The milling machine is controlled by the FANUC Series 31i-MODEL B controller. The working table of the machine has a surface area (L x W) of 2000 x 920 mm and enables the processing of a workpiece with a maximum weight of 3000 kg. The HCMC 1892 CNC milling center is equipped with a spindle that rotates at a maximum possible speed of 8000 rpm. The distance of the spindle face to the table is 1020 mm. In addition, the HMCM-1892 machining center is equipped, among others, with an automatic lubrication system, a screw chip conveyor and hardened slide guides secured with telescopic protective covers. The machine is fully operational, it has been regularly serviced – the spindle (2021), the Z axis ruler (2017) and the Z axis propeller bearings (2017) have been replaced.

Technical data of the HARTFORD HCMC-1892 milling center

– dimensions of the working table: 2000 x 920 mm

– maximum table load: 3 tons

– X / Y / Z axes: 1800/920/700 mm

– rapid traverse speed (changing) in the X / Y / Z axes: 15,000 mm / min

– weight with the holder: 15 kg – for the BT-50 cone

– maximum tool diameter: 125 mm

– maximum tool length: 300 mm

– maximum spindle speed: 8000 rpm

– distance of the spindle face to the table: 1020 mm

– distance of the spindle axis from the column: 1025 mm

– cutting speed: 1 – 7000 mm / min

– tool magazine in vertical arrangement (type S): 20 holders

– tool magazine in a horizontal configuration (type A): 32 holders

– main engine power: 15 kW

– XYZ axis drive motors power: 7 kW

– vertical spindle with a cone seat: BT-50 / CAT – 50 (at higher speeds BT-40)

– machine dimensions (length x height x width): 4700 x 3950 x 3340 mm

– weight: 17 t

Accessories for the HARTFORD HCMC-1892 CNC milling machine

– CNC control: FANUC Series 31i-MODEL B

– blowing the spindle with compressed air

– tool clamping system with a disc spring

– automatic lubrication system

– screw chip conveyor: 2 pieces

– Hardened sliding guides secured with telescopic protective covers

– ball screw ball gears on all axes

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano