The HEGENSCHEIDT 7893 crankshaft deep rolling and roll straightening machine was manufactured in 2002 by HEGENSCHEIDT-MFD GmbH & Co. KG in Germany. The machine is designed for roll recessing and straightening rolling of crankshafts in order to increase the fatigue strength of crankshafts. In the area of the rounds, an inherent compressive stress is introduced, resulting in the desired increase in strength. The material is strengthened with a simultaneous increase in surface hardness and the dynamic load capacity of the crankshaft is significantly increased.

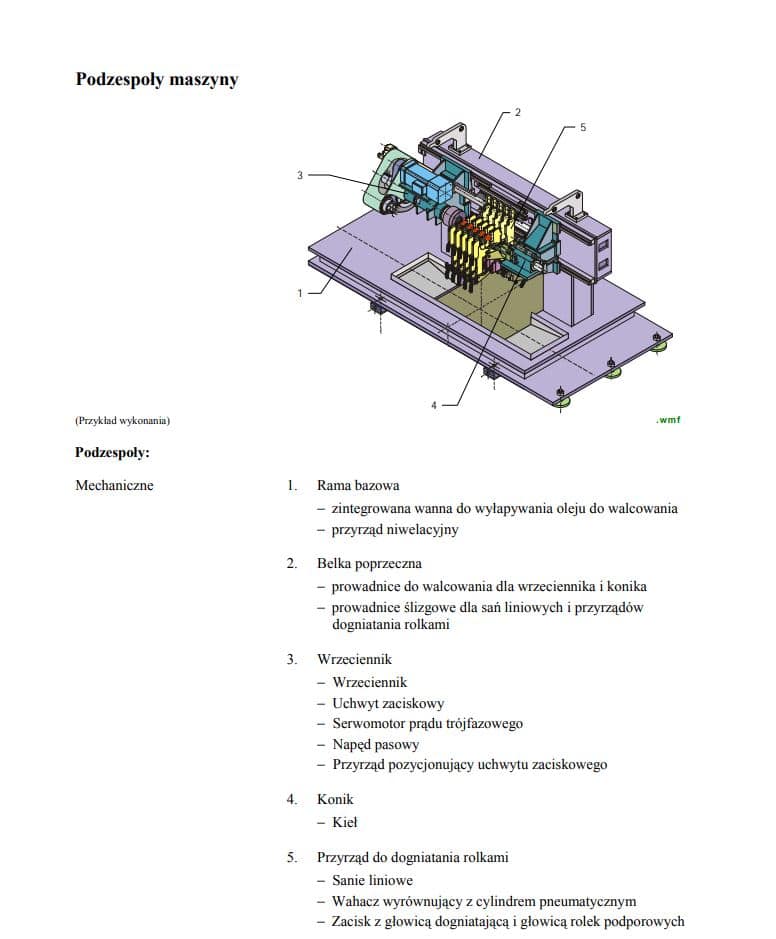

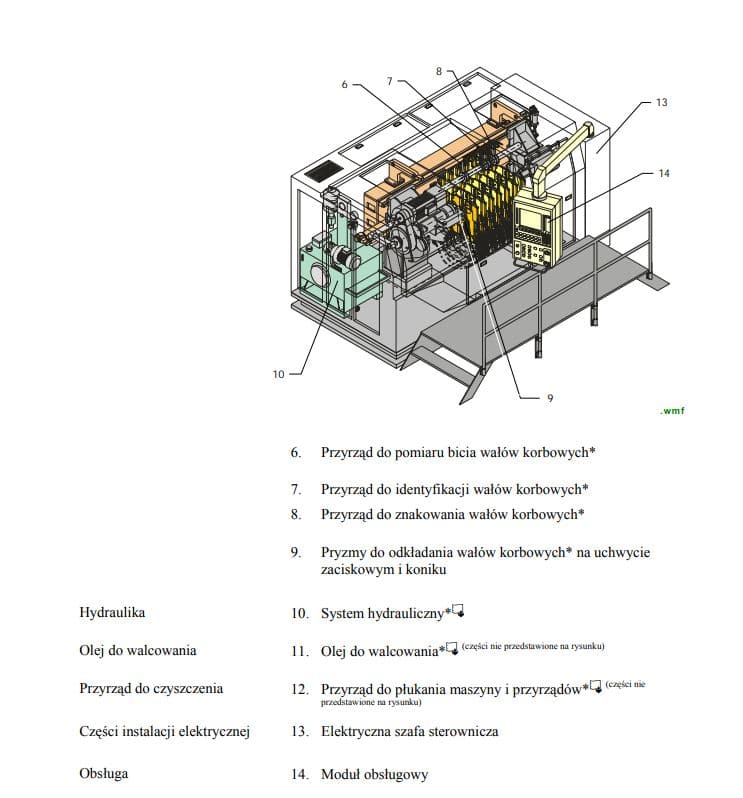

The patented machine design has space for up to 13 roller tools. All jigs for processing bearings are suspended by weight-compensated pneumatic cylinders. The tools are axially supported by side brackets when the main bearings are open (journal or flange side). The crankshaft compression and straightening functions can be controlled individually for each instrument and each bearing. Depending on the requirements, the respective jigs must be set to the operating or parking positions. Connections for the hydraulic system, the rolling oil system, the pneumatic system and the measuring transducers for the force and position sensors are integrated in the gages. All connections are protected by covers and cable ducts.

The machine is controlled by a SIEMENS Sinumerik CNC control. The crimping speed is 120 rpm and the straightening speed is 30 rpm. At the working crimp force there are 6 retractions and at increasing or decreasing the crimp force there are 3 retractions. The minimum bearing diameter is 30 mm and the maximum bearing diameter is 82 mm. The total weight of the HEGENSCHEIDT 7893 deep rolling and roll straightening machine for crankshafts is 13700 kg.

Technical data of the HEGENSCHEIDT 7893 machine

– crimping speed: 120 rpm

– straightening speed 30 rpm

– stroke of main bearing external crankshaft: max. 700 mm

– number of rollers kneading devices: 9 pieces

– number of rollers when increasing or decreasing the crushing force: 3

– number of crimping at working crushing force: 6

– maximum number of main bearings: 7

– maximum number of needle roller bearings: 6

– minimum distance between main and needle roller bearings: 29.5 mm

– minimum bearing diameter: 30 mm

– maximum bearing diameter: 82 mm

– minimum bearing width: 18 mm

– maximum stroke: 120 mm

– diameter of sled: 195 mm

– filling quantity of hydraulic system: 160 l

– working pressure of hydraulic system: 9/16 MPa

– cooling capacity of hydraulic system: 7 kW

– cooling water consumption in the hydraulic system: 3.8 m3/h

– filling quantity of the rolling oil aggregate: 30 l

– working pressure of oil aggregate for rolling: 1.5 MPa

– rolling oil consumption: 0.12 cm3/min

– filling quantity of rolling oil tank: 260 l

– working pressure of rolling oil tank: 0.5 MPa

– sound pressure level: 62 dB(A)

– peak value of acoustic pressure: 96.7 dB(C)

– capacity of return-circulation pump: approx. 25 l/min

– compressed air operating pressure: 0.4 MPa

– compressed air consumption: 10 m3/h

– maximum operating pressure of cooling water: 3 MPa

– cooling water consumption: 4.8 m3/h

– mains/connection voltage: 230/400 V

– voltage tolerance ± 15 %

– mains frequency: 50 Hz

– rated current: 50 A

– connection power: 35 kVa

– control voltage: 230 VAC

– valve voltage: 24 VDC

– PLC input and output voltage: 24 VDC

– machine weight HEGENSCHEIDT 7893 with all equipment: 13700 kg

HEGENSCHEIDT 7893 machine equipment

– CNC control: SIEMENS Sinumerik

– hydraulic aggregate: REXROTH

– rolling oil filtration system

– cleaning device for instruments and tools

– tool lubrication system

– safety housing and operator platform

– roller pinching device

– tailstock with spindle sleeve

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe