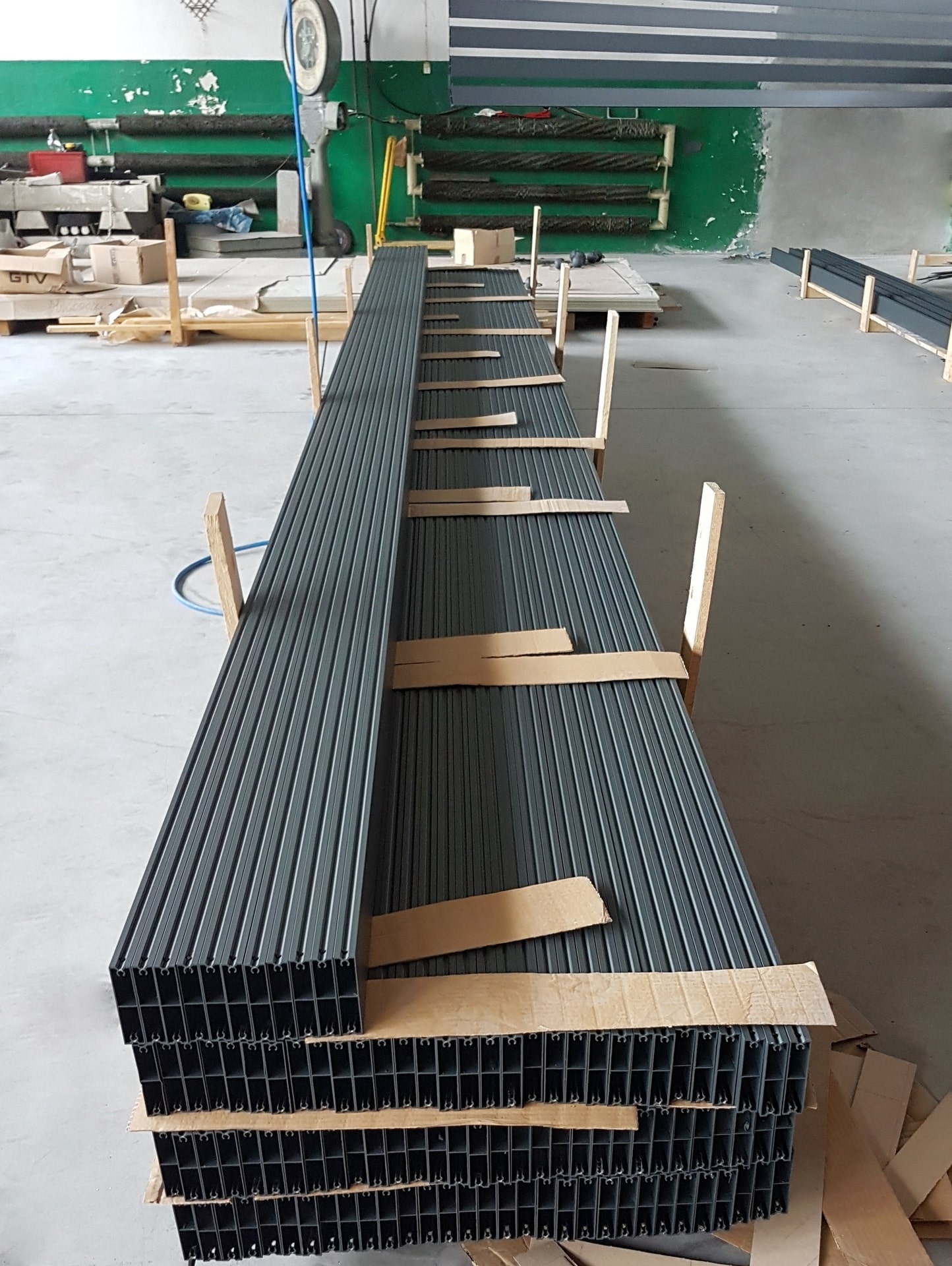

IDEAL-LINE powder coating plant was manufactured in Denmark in 1990. The powder coating line fully automatically coats workpieces with a maximum length of 600 cm, a width of 40 cm and a height of 100 cm with a special powder coating, using an overhead conveyor. The conveyor chain is set in motion by two drive units, guaranteeing the smooth movement of the workpieces between the successive treatment stages. Powder coating using the IDEAL LINE automatic powder coating line is characterised by the highest quality and precision.

The IDEAL LINE complete powder coating plant consists of:

– paint booth (2 pcs.)

– paint column (2 pcs.)

– paint furnace (2 pcs.)

– complete torch for paint furnace (2 pcs.)

– paint booth platform

– paint furnace blowing fans (4 pcs.)

– cassettes for closing furnace (4 pcs.)

– powder spray guns

– track

– chain conveyor drives (2 pcs.)

– conveyor chain

– control cabinet

– powder recovery station (2 pcs.)

– dust collector

– built-in dust collector fan

– dust collector regeneration manifolds (2 pcs.)

– pipes for cyclone

– dust collector cyclone

– small axial fan

– axial fan brender

– ventilation piping

– exhaust pipes (4 pcs)

Technical parameters of the IDEAL-LINE powder coating plant

- maximum profile dimensions (L x W x H): 600 cm x 40 cm x 100 cm

- paint furnaces length: 10.7 m and 12 m

- machine length: approx. 50 m

- machine width: approx. 10 m

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe