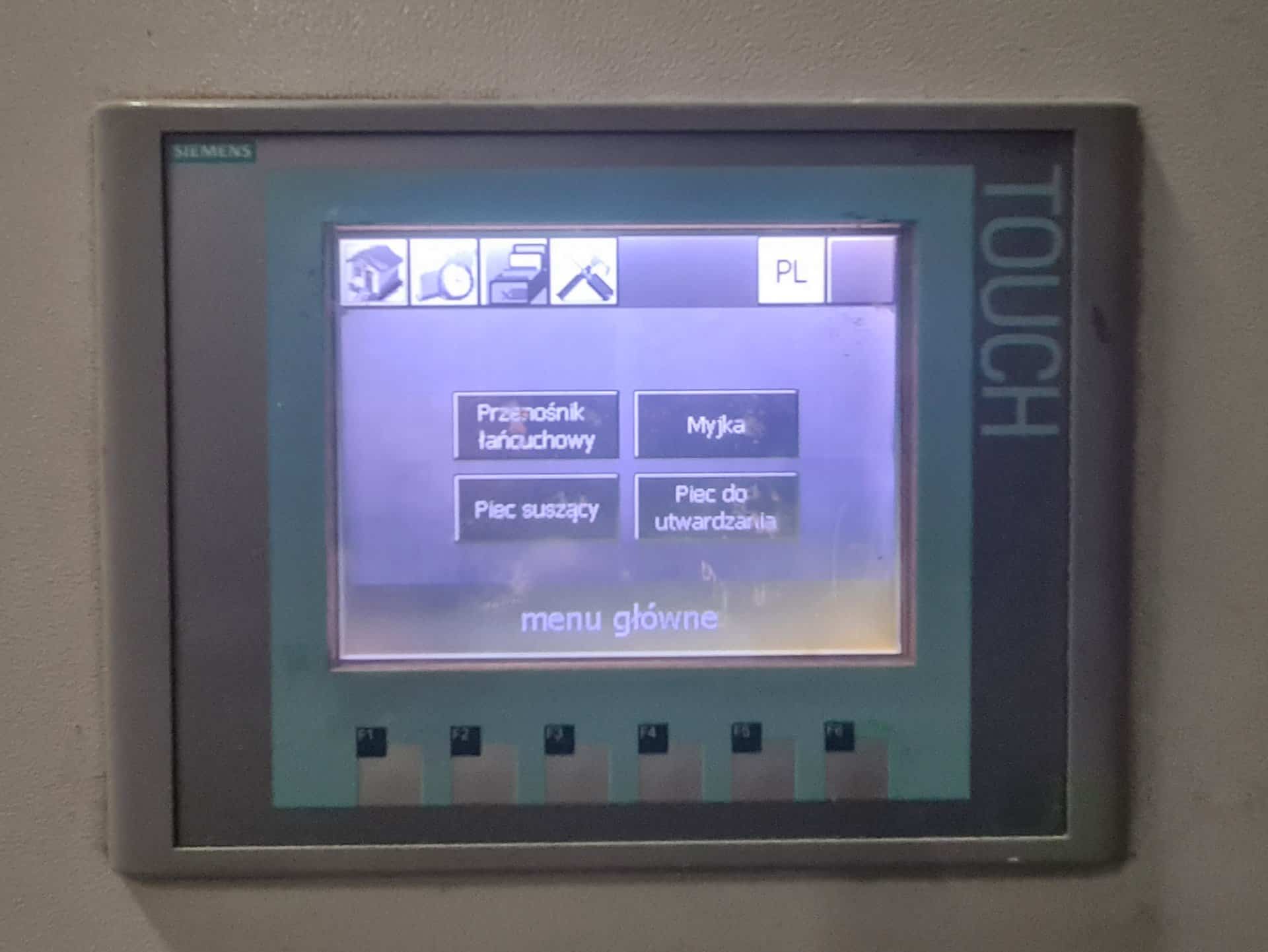

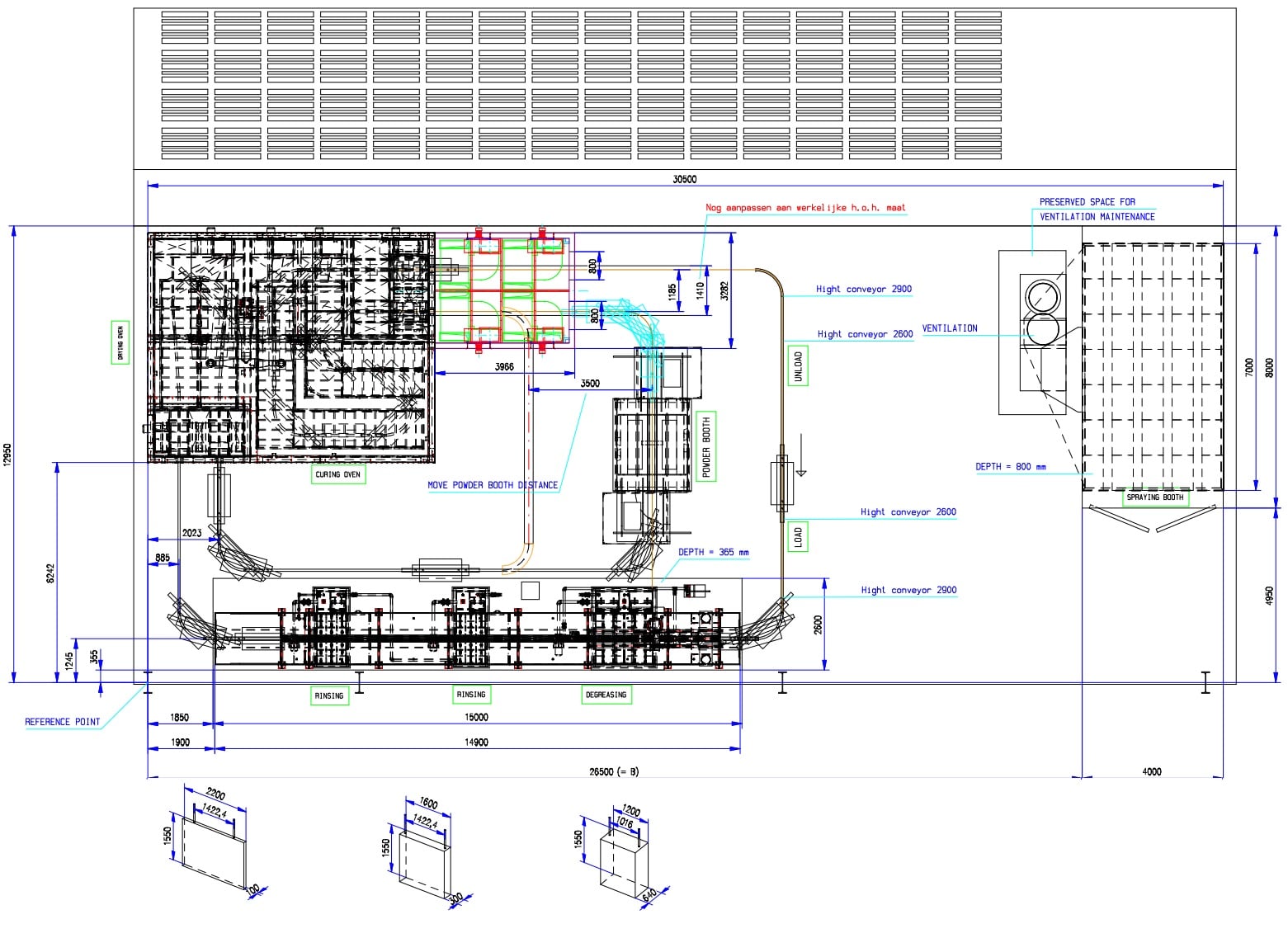

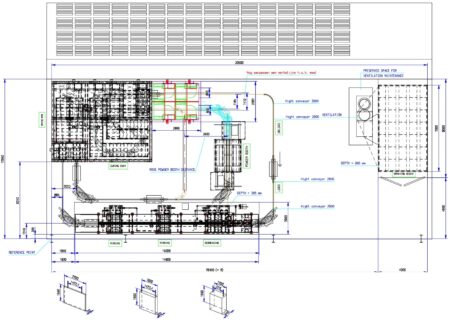

The INDUFINISH powder coating plant was built in 2013 by the Dutch company LBtec Indufinish b.v. The powder coating plant consists of the following elements: pretreatment tunnel, washing chamber, drying/heating oven, demineralised water station, INOX paint booth. The entire system is controlled by a PLC control system SIEMENS.

The conveyor line moves at an average speed of 0.8 m/min ( it is possible to adjust the speed within the range of 0.5 to 3 m/min).It is equipped with 600 mm long hooks, on which workpieces with a maximum weight of 150 kg and with dimensions (L x W x H) of 2200 x 640 x 1550 mm can be placed.

It is equipped with 600 mm long hooks, on which workpieces with a maximum weight of 150 kg and with dimensions (L x W x H) of 2200 x 640 x 1550 mm can be placed.

The pretreatment tunnel has a 1600 mm long spray system containing 70 nozzles with a capacity of 13.5 l/min. It also has a Lowara SH 50-125/5.5 spray pump with 5.5 kW and 2900 rpm.

The drying/curing oven is constructed of modular sandwich panels with mineral wool insulation at least 150 mm thick. The interior is made of galvanised steel sheet with a thickness of min. 25 µ. Heat transfer to the workpieces takes place through air convection.

The combustion gases from the modulating burner flow through a heat-resistant stainless steel burner pipe, which evenly mixes the gases throughout the burner chamber. A constant volume of air is extracted through the outlet pipe and led outside, where it is automatically replaced by fresh air through standard openings.

Before the paint shop is dismantled, it is possible to give the customer training in the use of the INDUFINISH powder coating plant in the price of the machine. It is also possible to purchase two gas boilers of 65 kW each.

General specifications of the INDUFINISH powder coating plant

- PLC controller: SIEMENS

- conveying line speed: 0,5 – 3m/min

- maximum workpiece weight: 150 kg

- dimensions of workpiece (L x W x H): 2200 x 640 x 1550 mm

- length of hooks: 600 mm

- heating energy: gas

- electrical connection: 3 x 400 V + N + Pe

- compressed air: 6 bar

Detailed technical parameters of individual elements of the INDUFINISH powder coating plant

PRETREATMENT TUNNEL

Spraying system

- length: 1,600 mm

- spraying collars: 5 pcs.

- nozzles/bar: 14 pcs.

- nozzle output: 13.5 l/min @ 1.2 bar

- total number of nozzles: 70

- nozzle type: V-jett polyprop

Spraying pump

- type: horizontal, centrifugal

- pump: Lowara SH 50-125/5.5

- material: stainless steel 304

- impeller material: stainless steel 304

- sealing type: mechanical seal Sic/Car

- capacity: 57 m³/h

- pressure: 1.8 bar

- power: 5.5 kW

- speed: 2.900 rpm

Heating

- medium: hot water

- power: 200 kW

- heat exchanger: heat exchanger with cleaning connections (Alfa Laval)

- refrigerant pump: 304 stainless steel

- capacity: 20 m³/h

- power: 0.75 kW

Tank

- volume: 2.3 m³

- height of liquid: 700 mm

- Tank material: PP

- insulation: 50 mm

- dimensions (L x W x H): 1700 x 2150 x 800 mm

WASHING CHAMBER

Spraying system

- length: 800 mm

- spraying collars: 3 pcs.

- nozzles/bar: 14 pcs.

- nozzle output: 12 l/min @ 1,2 bar

- total number of nozzles: 42

- nozzle type: V-jett polyprop

Spraying pump

- type: horizontal, centrifugal

- pump: Lowara SH 32-160/22

- material: stainless steel 304

- impeller material: stainless steel 304

- sealing type: mechanical seal Sic/Car

- capacity: 30 m³/h

- pressure: 1.8 bar

- power: 1.5 kW

- speed: 2,900 rpm

Tank

- volume: 1.1 m³

- height of liquid: 700 mm

- dimensions (L x W x H): 1000 x 2150 x 800 mm

DRYING/CURING OVEN

- product entry temperature: 20 °C

- time in oven: 20-30 min.

- air temperature 200 °C

- maximum temperature: 225 °C

- burners: Weishaupt Type 1 WG 30 + 1 WG20

- maximum power: 470 kW

- nominal output: 380 kW

- air circulation: 36,000 m³/h

- number of fans: 3 pcs.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe