InfoTEC 4121 Energy CNC router was built in 2018 in Poland by 4CNC Sp. z o.o. The machine has worked for a small amount of time so far and has been used for milling parts made of dibond, plexiglass and foamed PVC.

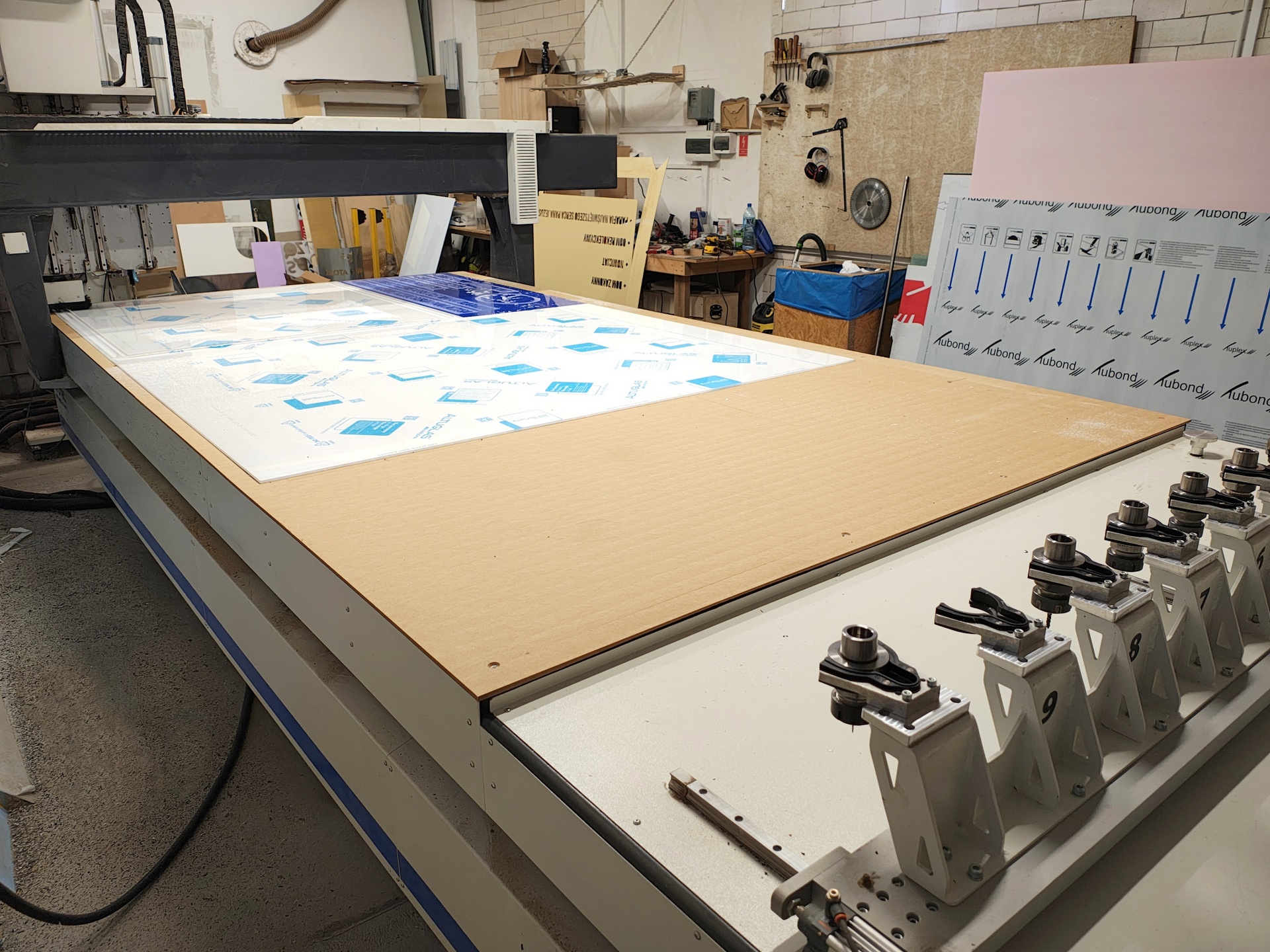

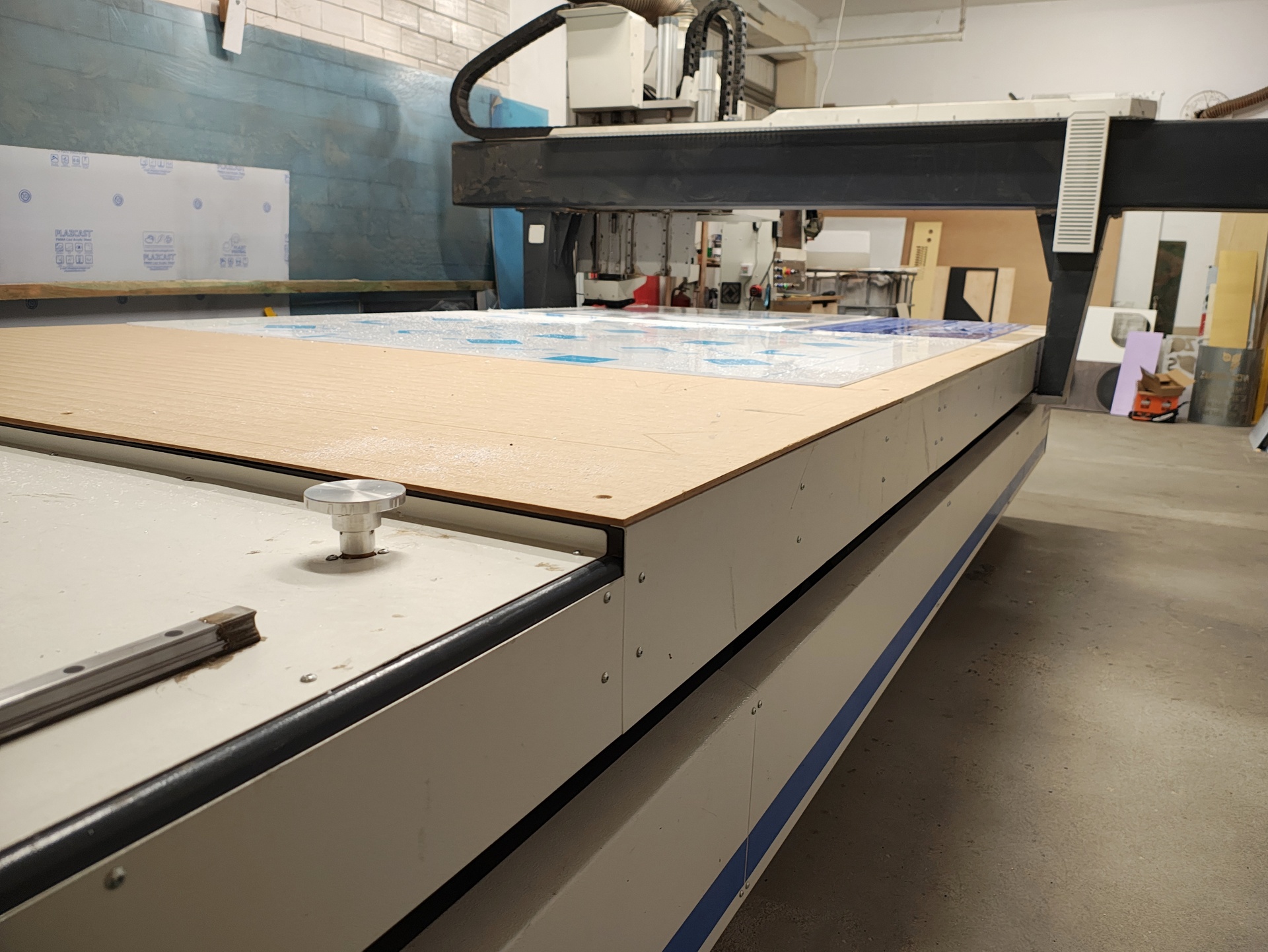

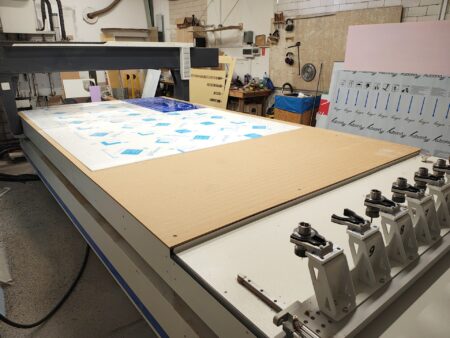

InfoTEC 4121E is used in precision machining of a wide range of materials, i.e. soft metals, wood and plastics. The machining process is performed on a large vacuum table by means of a high-speed spindle. Each axis is driven by powerful AC servo motors, which guarantee the achievement of excellent feed dynamics. Tools taken from a 10-position magazine are in turn continuously measured and calibrated by a special sensor to ensure maximum milling precision throughout the entire production cycle. All this is complemented by extensive equipment, consisting of, among others, a BECKER vacuum pump and CAD/CAM software. This all makes the offered InfoTEC 4121 CNC milling machine an excellent choice for companies with diverse production profiles. The total weight of the machine is 3500 kg.

Technical specifications of the InfoTEC 4121 Energy router

- machinable materials: soft metals, wood, wood-based materials, plastics, etc.

- feed in the X/Y/Z axis: 2100/4100/250 mm

- feed rate in the X/Y/Z axis: 80/80/12 m/min

- work area (L x W): 4100 x 2100 mm

- spindle taper: HSK F63

- spindle drive power: 8.5 kW

- tool holder: HSK63F

- vacuum pump power: 5.5 kW

- vacuum pump capacity: 250 m3

- power supply : 3x 400 V; 50/60 Hz

- weight of the InfoTEC 4121 Energy machine: 3500 kg

Equipment of InfoTEC milling machine

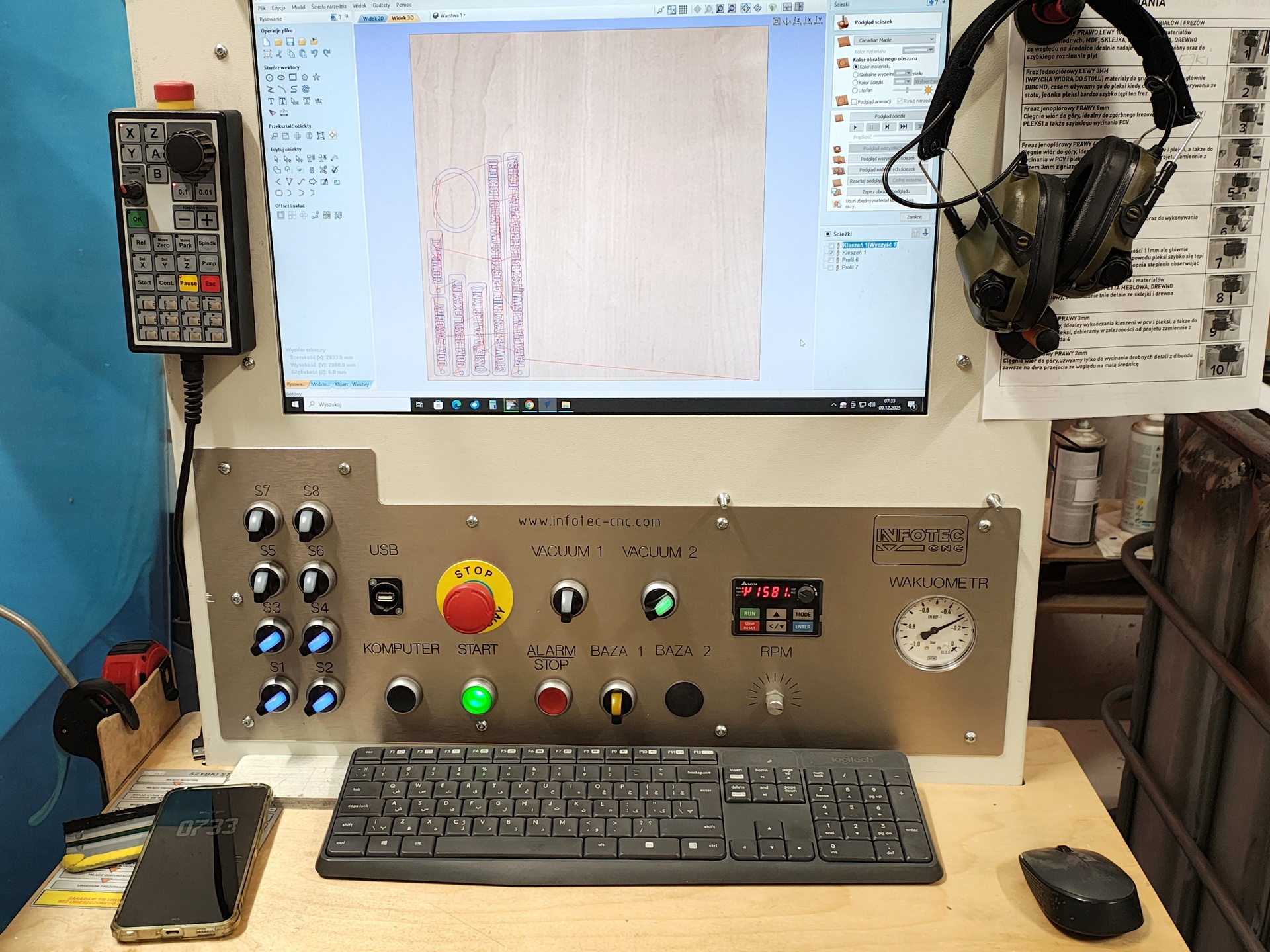

- CAD/CAM software: VCarve Pro

- CAM software: InfoCAM PRO V5

- HITECO spindle with air cooling system

- 10-position linear tool magazine with tool measurement sensor

- vacuum pump: BECKER

- vacuum table

- oil mist

- AC servo motors in all axes

- creasing wheel

- trailing knife

- chip extraction

- portable control unit (pendant)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe