JESCO JAGUAR 2280 ENC CNC lathe was built in 2014 in Taiwan by JESCO MACHINERY LTD. (Jessey). The machine, designed for precision machining of workpieces, is an excellent choice for any industrial plant. All machining operations are performed inside a large, fully illuminated workspace by means of a spindle made of high-quality alloy steel. In order to guarantee the highest accuracy over the entire speed range, the spindle is mounted on super-precision, pre-loaded bearings. Movement in the X and Z axes is in turn carried out on hardened and precision-ground ball screws. Both axes are driven by powerful AC servo motors with their own power supply and have individual electronic knobs for manual operation of the machine. This is all complemented by an intuitive CNC control with many useful functions. The JAGUAR 2280 ENC CNC lathe weighs approximately 4000 kg.

Technical specifications of the JESCO JAGUAR 2280 ENC CNC lathe

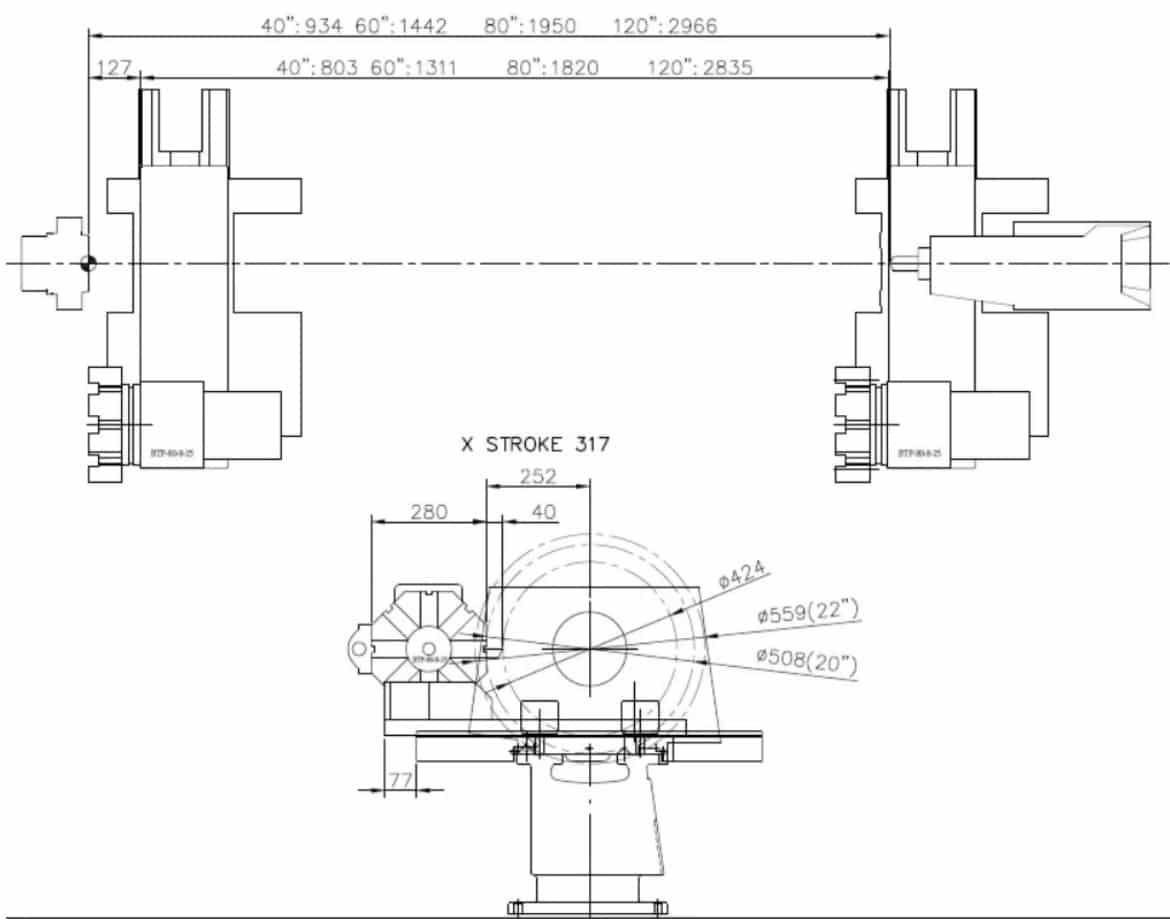

- swing over bed: 560 mm

- swing over cross slide: 390 mm

- swing over gap: 810 mm

- maximum turning length: 1650 mm

- distance between centres: 1950 mm

- maximum spindle rotational speed: 2400 rpm

- spindle bore diameter: 80 mm

- spindle end: D1-8

- bed width: 345 mm

- tailstock quill extension: 200 mm

- tailstock quill diameter: 75 mm

- tailstock quill taper: MT5

- power supply: 3x 400 V; 50 Hz

- dimensions (L x W x H): 4170 x 2100 x 2230 mm

- weight of the JESCO JAGUAR 2280 ENC machine: approx. 4000 kg

Equipment of the JAGUAR 2280ENC metal lathe

- CNC controller: FAGOR 8060FL

- tailstock

- automatic spindle ratio adjustment

- liquid cooling system

- oil cooler

- automatic lubrication system for slideways and ball screws

- workspace illumination

- levelling blocks

(The technical parameters given were obtained from the machine manufacturer’s website. Their accuracy cannot be guaranteed and they may therefore differ slightly from reality.)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe