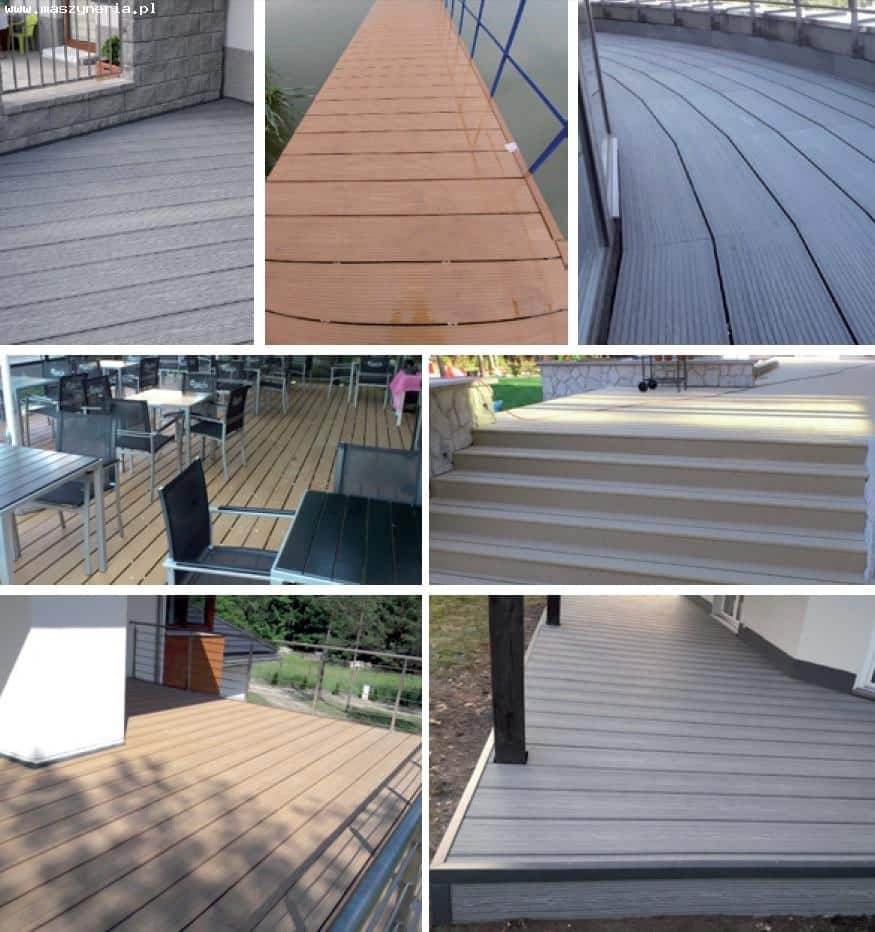

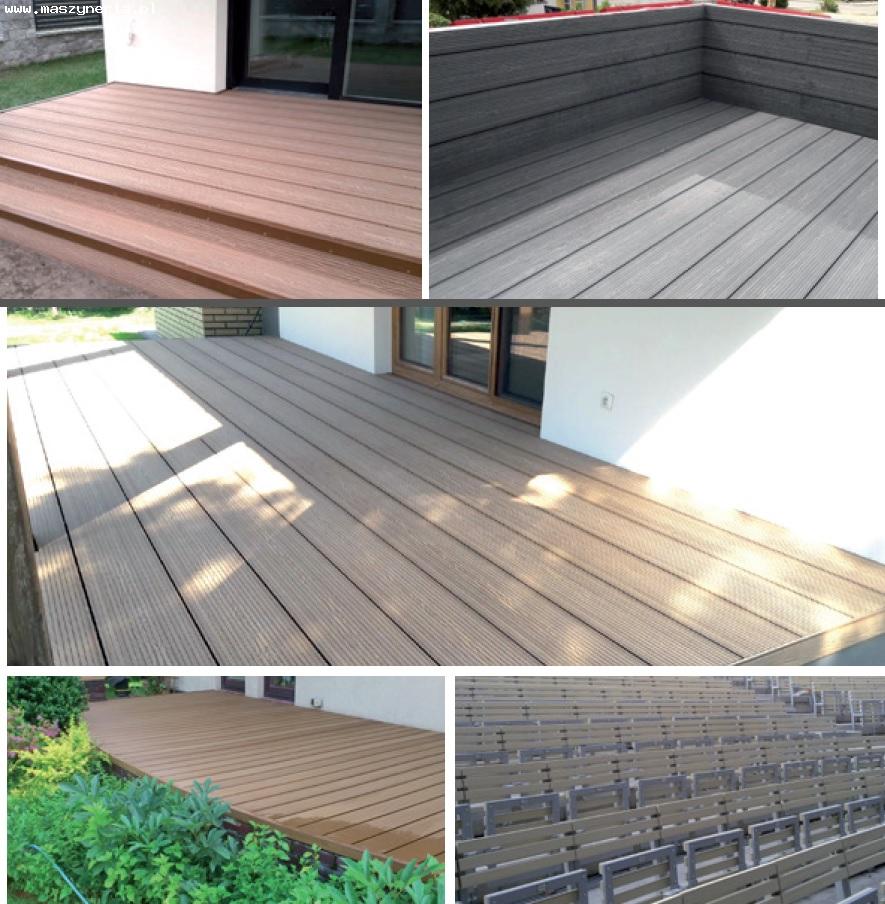

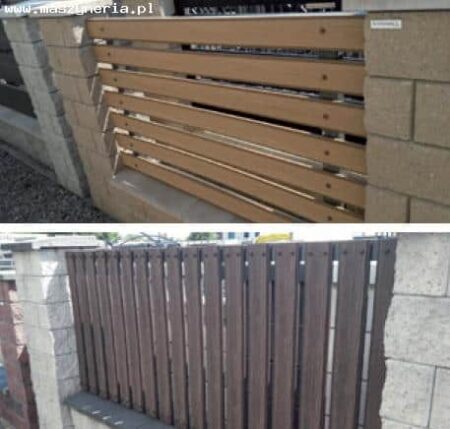

JWELL SJZ 80/156 extruder for PVC profiles was produced in 2017. It is a technological line for the production of composite products based on wood flour and PVC. The co-extrusion line was used primarily for the production of composite boards, rails and facade profiles. The extruder for composite decking boards is complete. Minimal human work is required to operate the machine, as it is controlled automatically. The line is used for the production of, among others, terrace composite boards, facade profiles, fence rails, paneling, corners, joists and fence profiles.

Composition of JWELL SJZ 80/156 extruder for PVC profiles

– SJZ 80/156 twin-screw extruder, capacity 300 kg/h, 4 heating zones

– SJZ 45/100 twin-screw extruder, capacity 60 kg/h, 3 heating zones

– vacuum feeder: 2 pieces (universal vacuum feeder for plastic with a transmission for 10 meters)

– a device for hot firing the wood structure

– brushing machine

– miksea 300/6005 with a capacity of 300 liters

– mold for co-extrusion of composite board: 245 mm

– mold for co-extrusion of paneling

– double form for the corner: 60 x 40 x 4 mm

– double joist form: 50 x 30 mm

– double form for a fence profile: 100 x 15 mm

– DYPS 450 crusher with a capacity of up to 150 kg/h

– SMP 600 pulverizing machine with a capacity of up to 500 kg/h

– T strip

– calibration table

– caterpillar haul-off

– saw

– putter

– clip dies, two types

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe