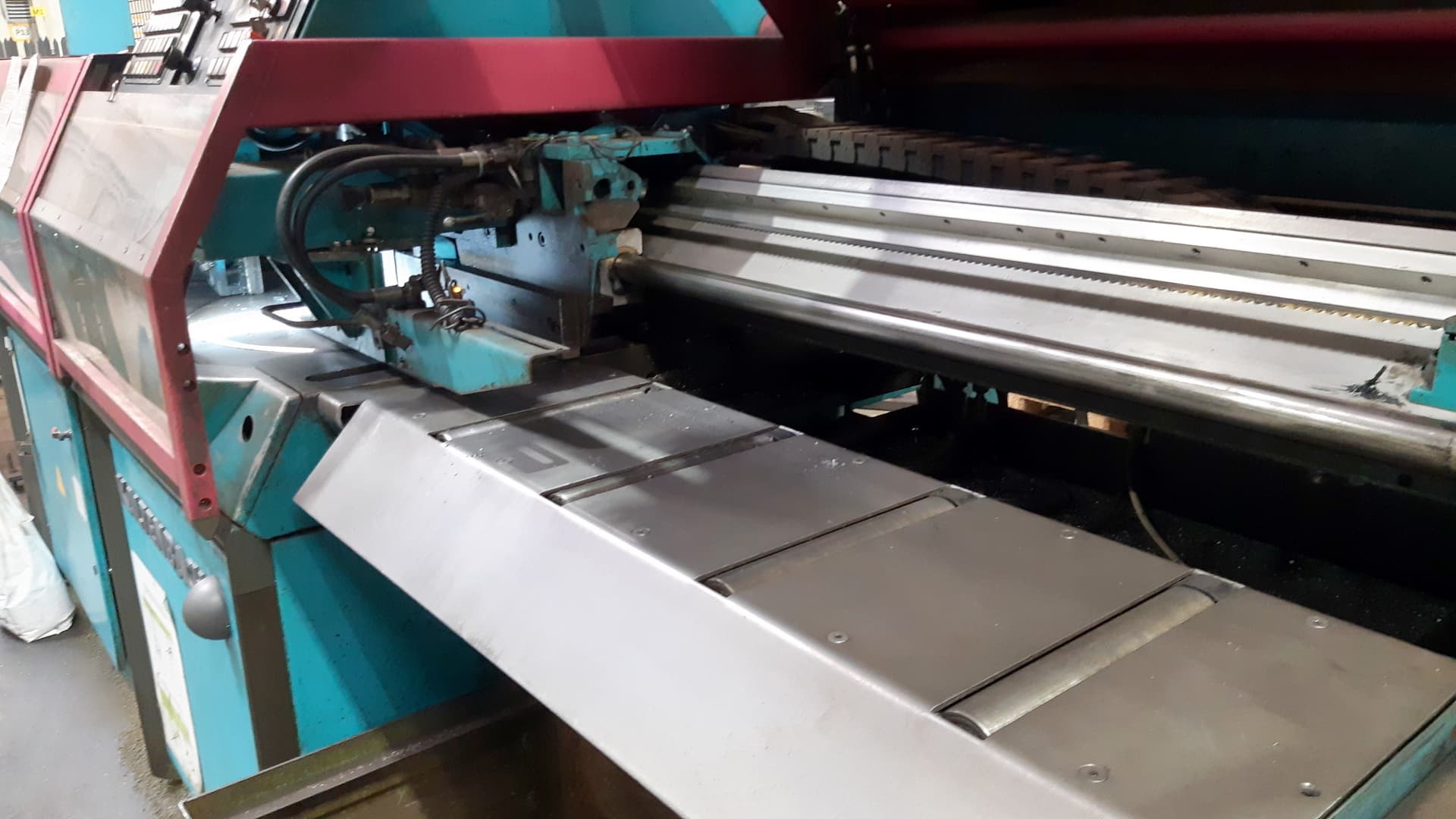

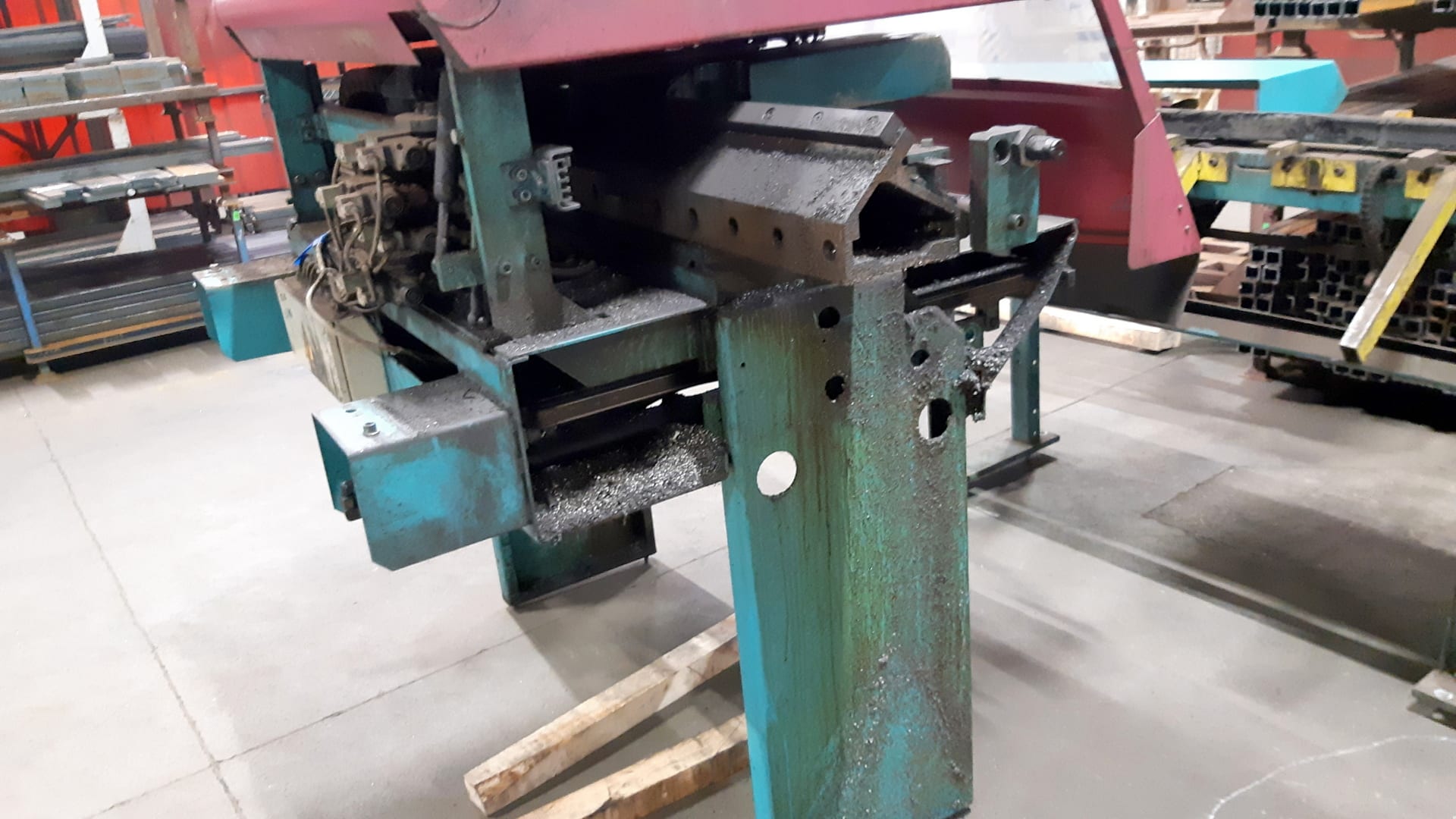

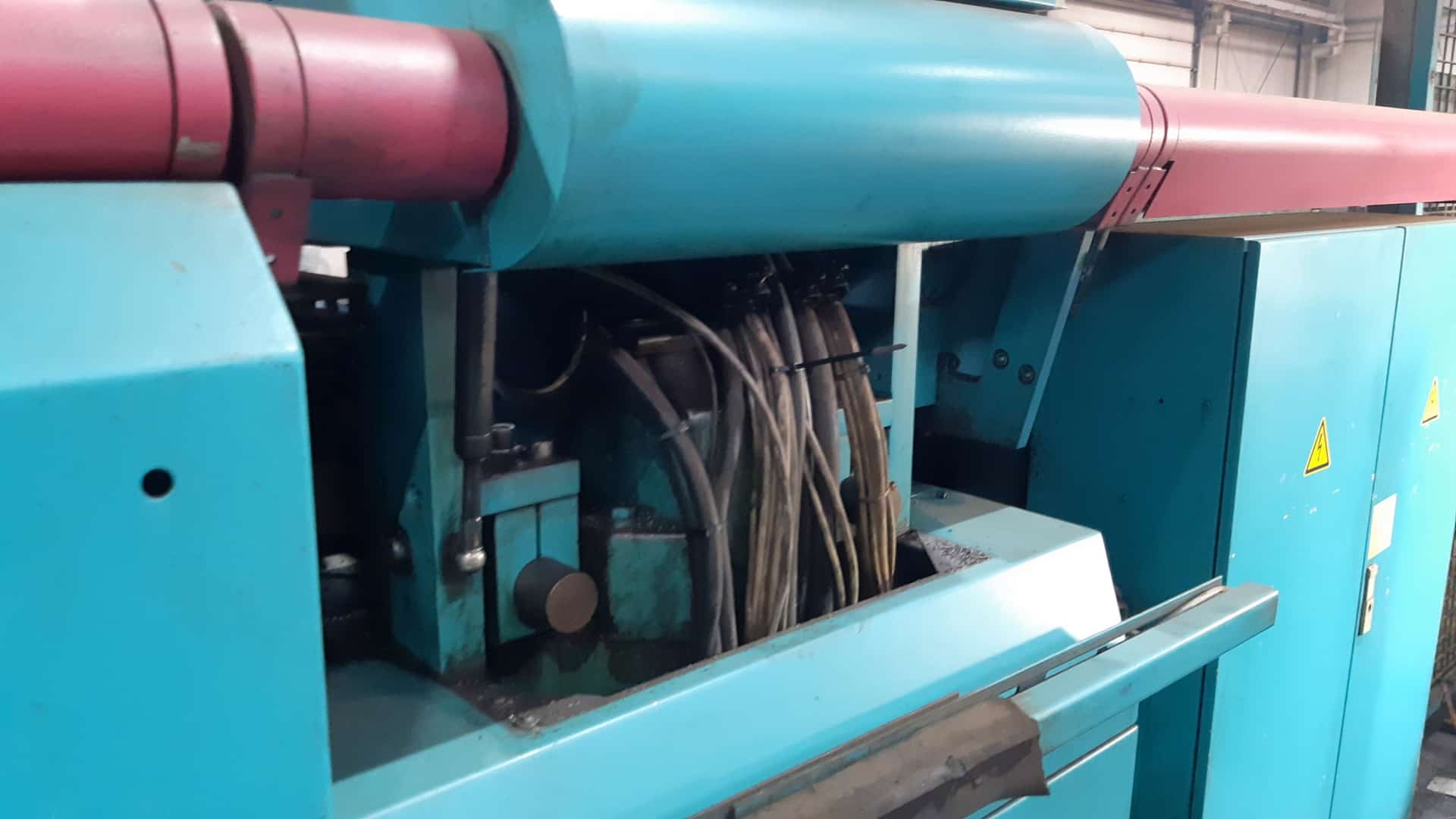

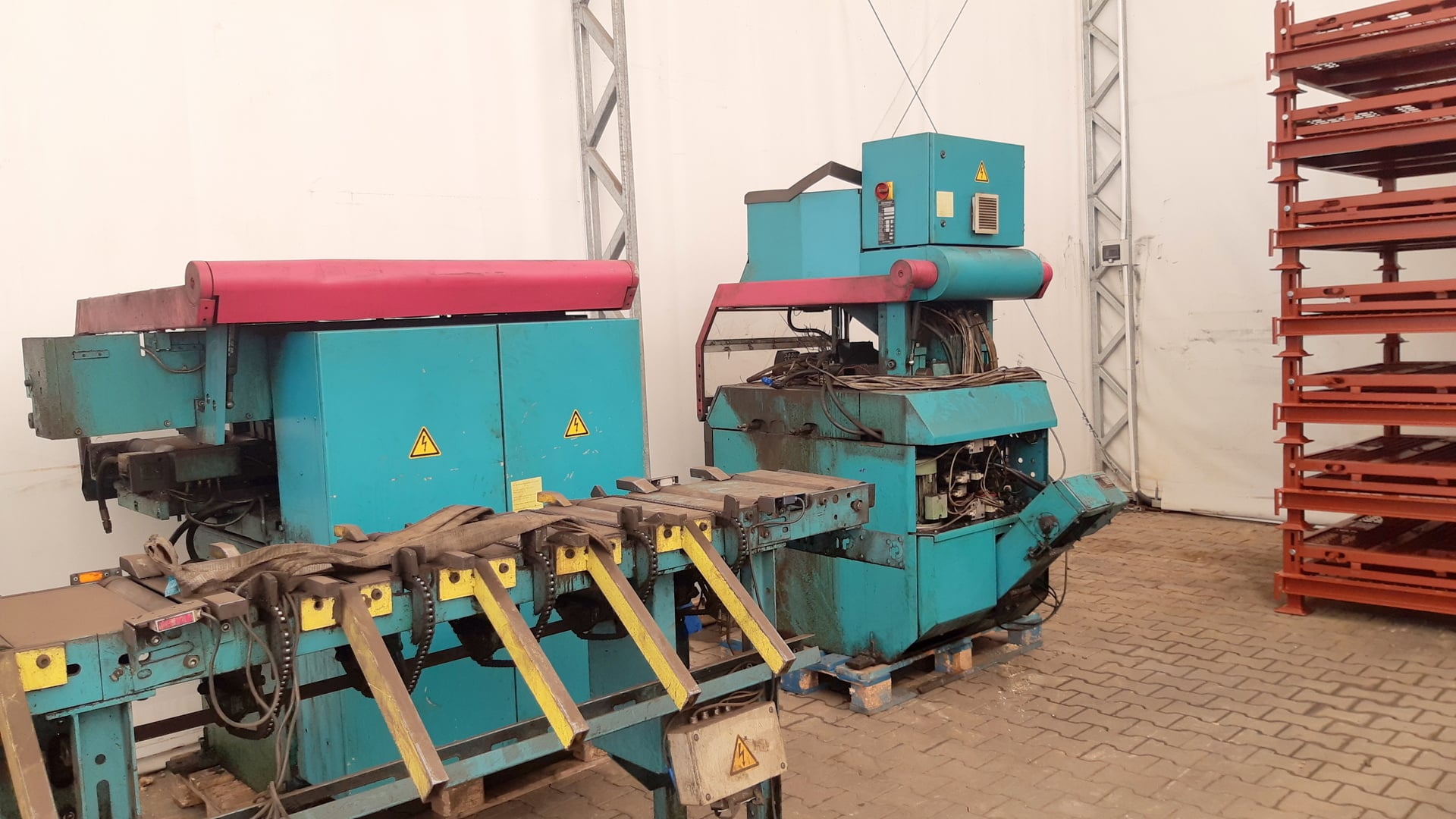

KALTENBACH KKS 400 NA automatic circular sawing machine built in Germany is used for the precise, fully automatic cutting of flat bars, angle bars, profiles and tubes. The machine uses a reliable drive with hardened and ground helical gears, which, in combination with the electronic cutting height adjustment and the fast reverse movement of the cutting disc, ensures smooth operation and short cutting times, even during the most demanding processing. A large workspace with a clamping element stiffens the material during cutting, ensuring that the workpiece is held firmly and securely on both sides of the 400 mm diameter blade. The KALTENBACH circular sawing machine is offered with, among others, a material feeder, chip conveyor and convenient to use PLC control.

Technical data of the KALTENBACH KKS 400 NA circular sawing machine

- PLC control

- machinable materials: steel, stainless steel, non-ferrous metals

- maximum cutting capacity (square): 120 mm

- maximum cutting capacity (flat bar): 305×20 mm

- maximum cutting capacity (round): 130 mm

- cutting angle: 0-180°

- cutting disc feed: 0-1000 mm/min

- rapid traverse of the cutting disc: 3300 mm

- cutting disc diameter: 400 mm

- material feeder

- chip conveyor

- DTR – Technical and Operational Documentation

- operating manual

- PLC control backup

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe