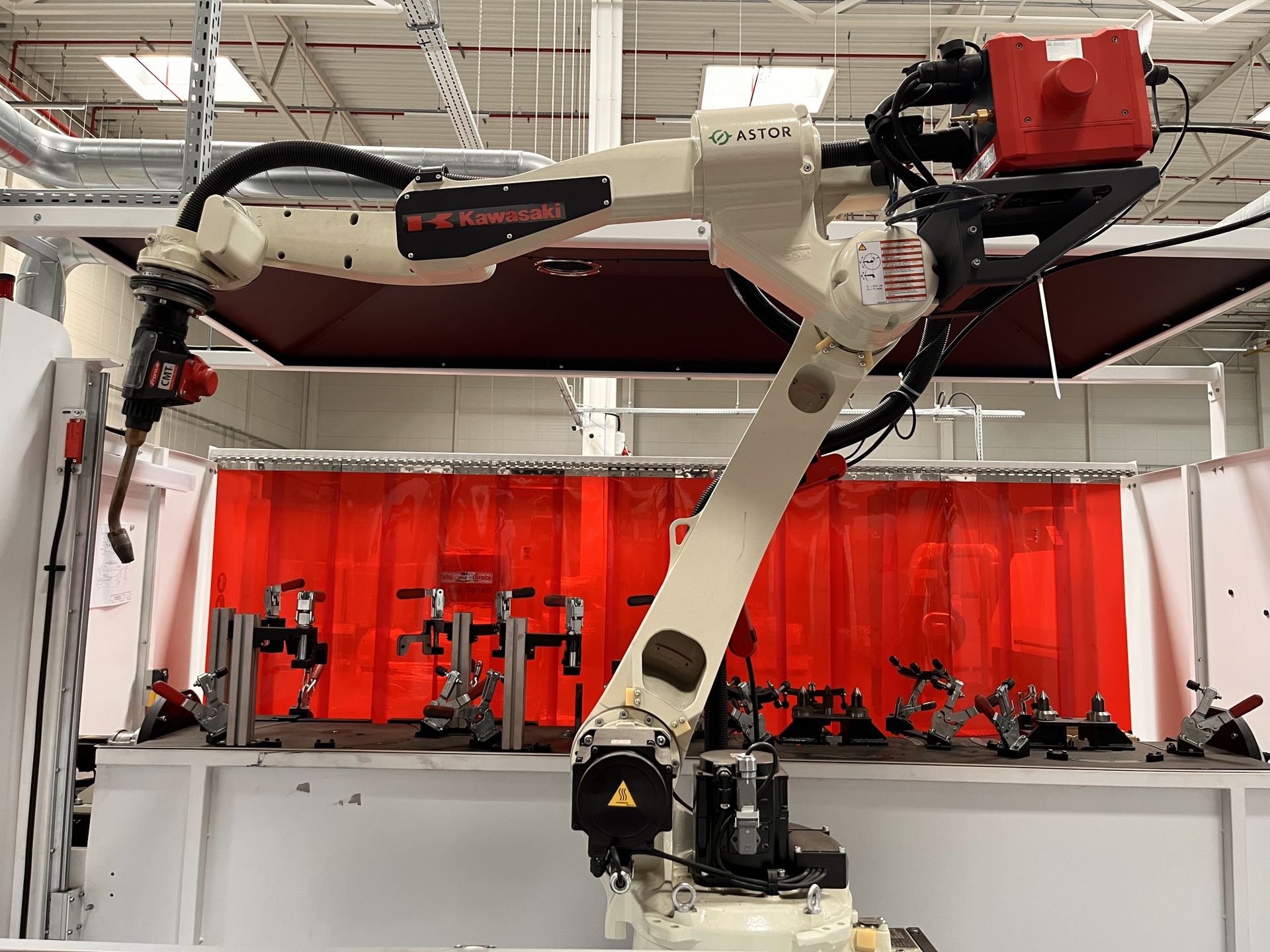

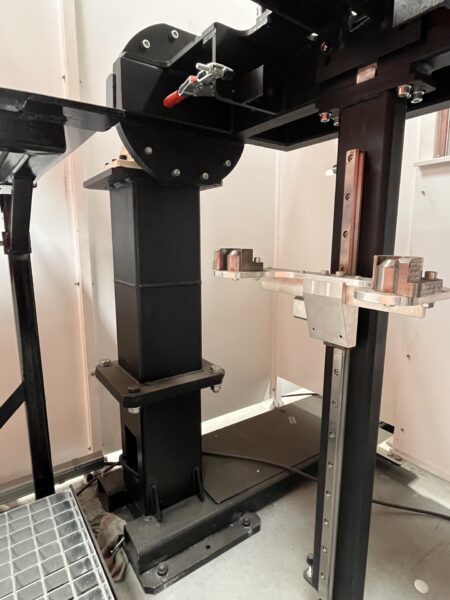

KAWASAKI BA006L-A robotic welding station was built in 2022. This system, composed of devices and machines with the best technical parameters, is the perfect choice for fully automatic arc welding using the MIG/MAG method. All the components of the station are integrated inside an enclosed structure.

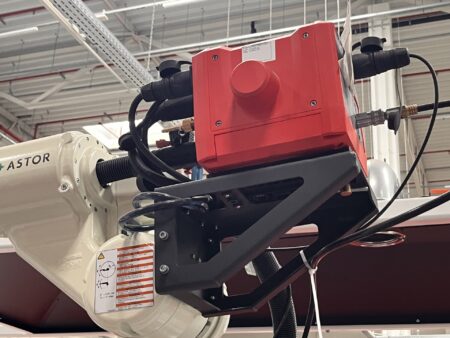

The machining process is performed by a KAWASAKI 6-axis robot distinguished by, among others, its sophisticated design and robust arm with an increased range of movement. In order to achieve excellent dynamic movements combined with high process reliability, each of its six axes is driven by efficient servo motors. What’s more, a number of state-of-the-art systems ensure uninterrupted operation of the machine, without any downtime.

The entire workspace is ventilated from welding fumes by powerful KEMPER extraction units. This solution significantly improves overall safety and comfort.

The robotic welding cell on offer is fully complete and consists of the following components:

– robot arm: KAWASAKI 3BA006L-AC01

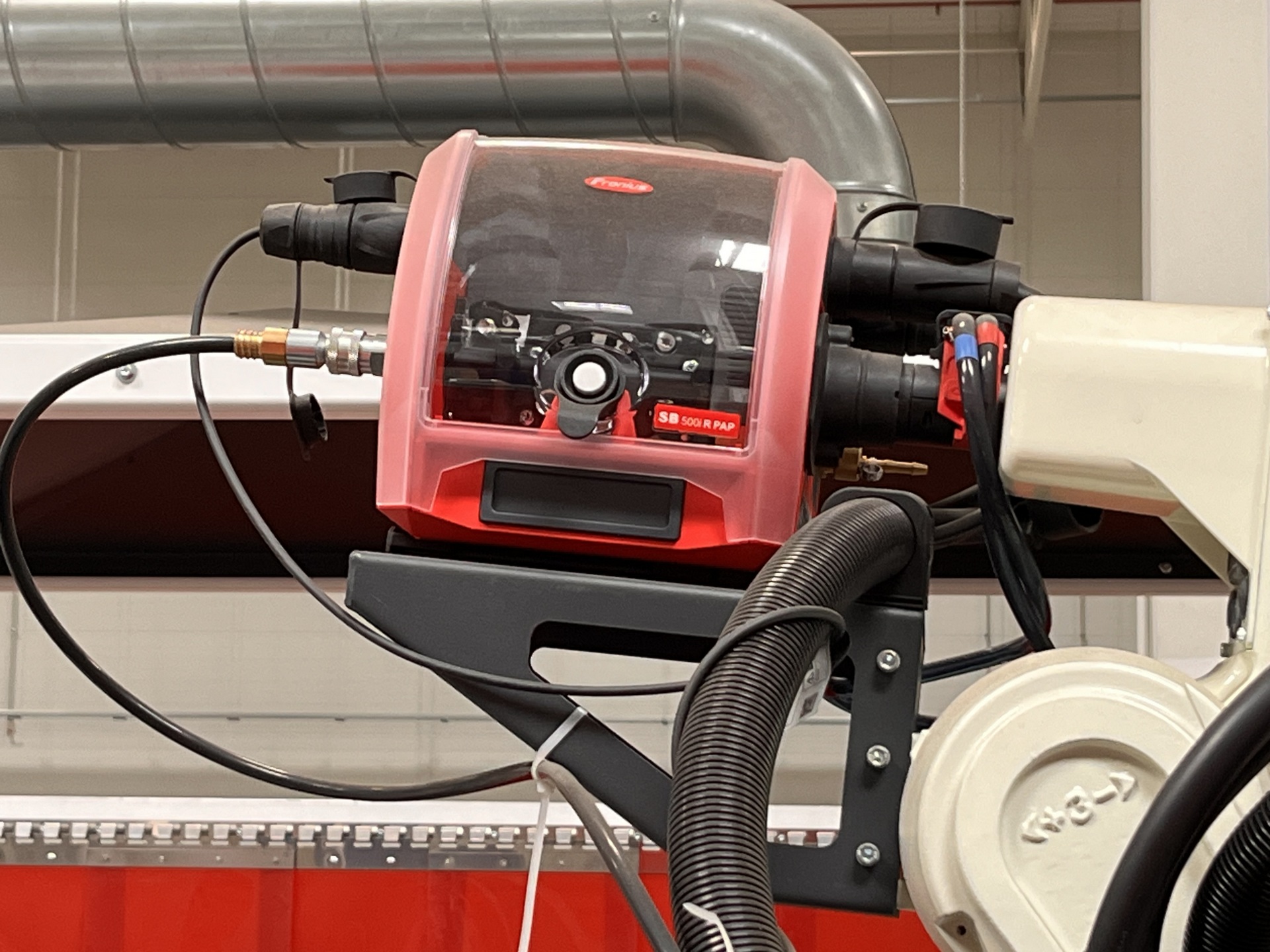

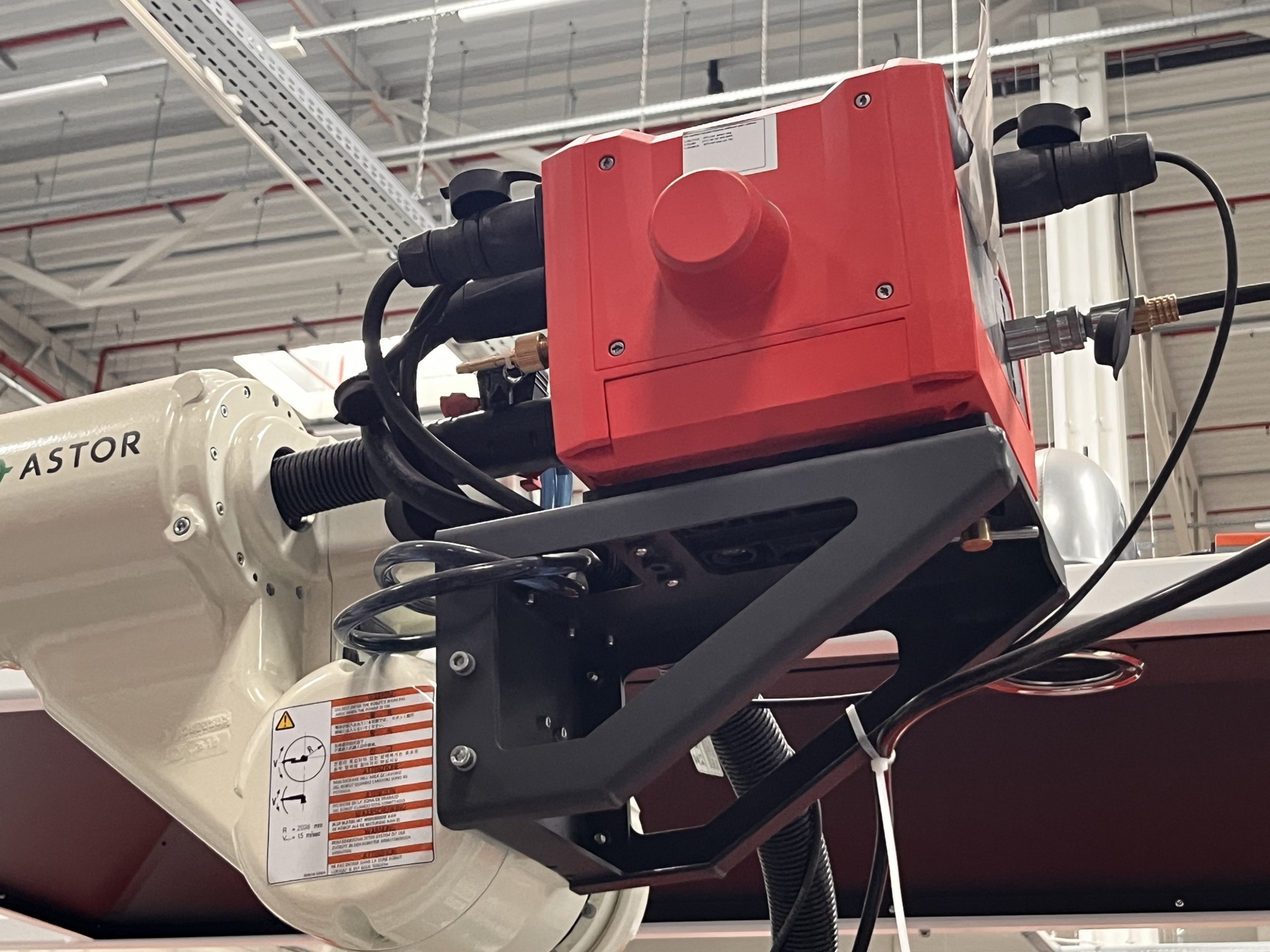

– MIG/MAG welder: FRONIUS TPS 400i

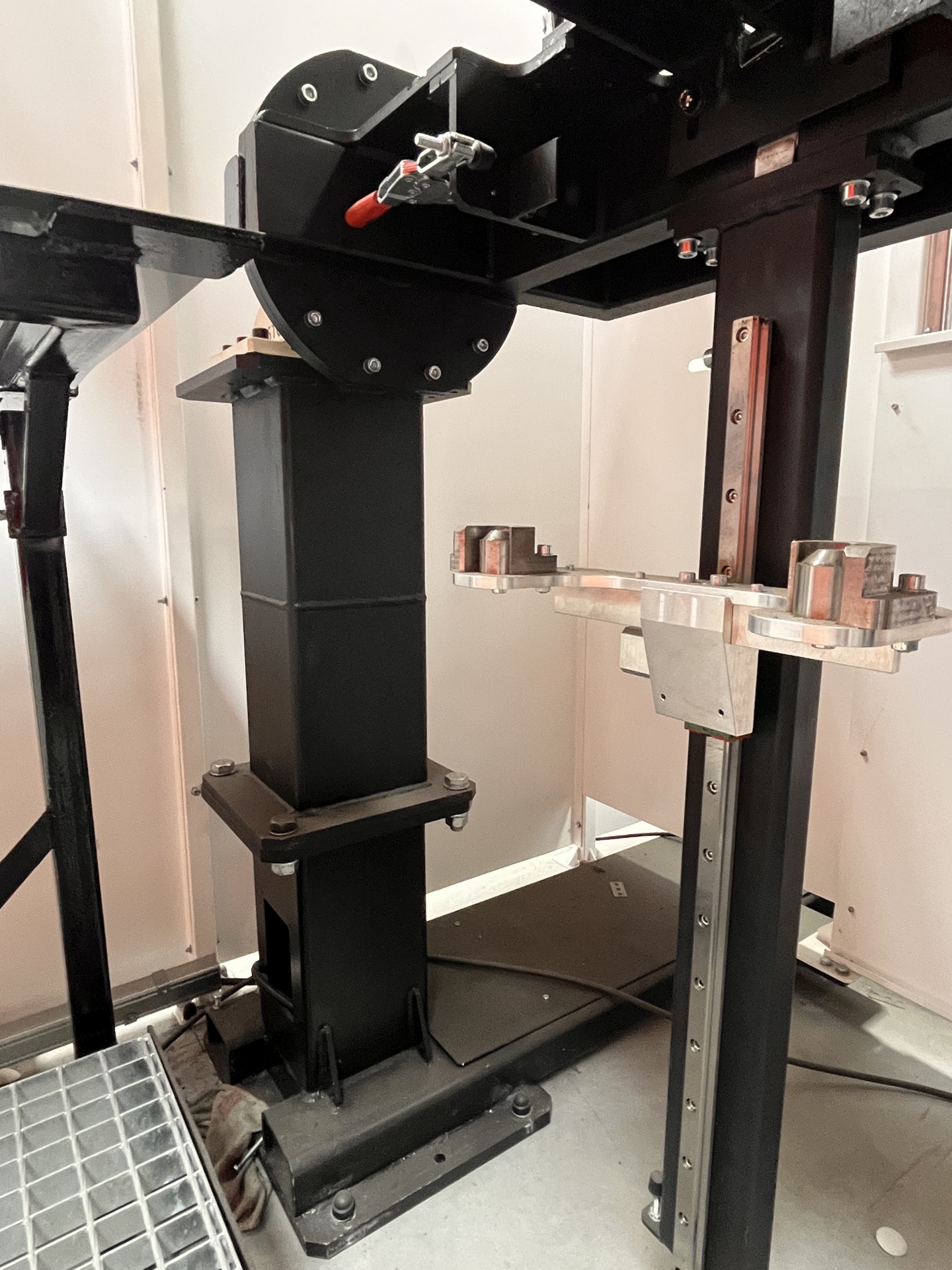

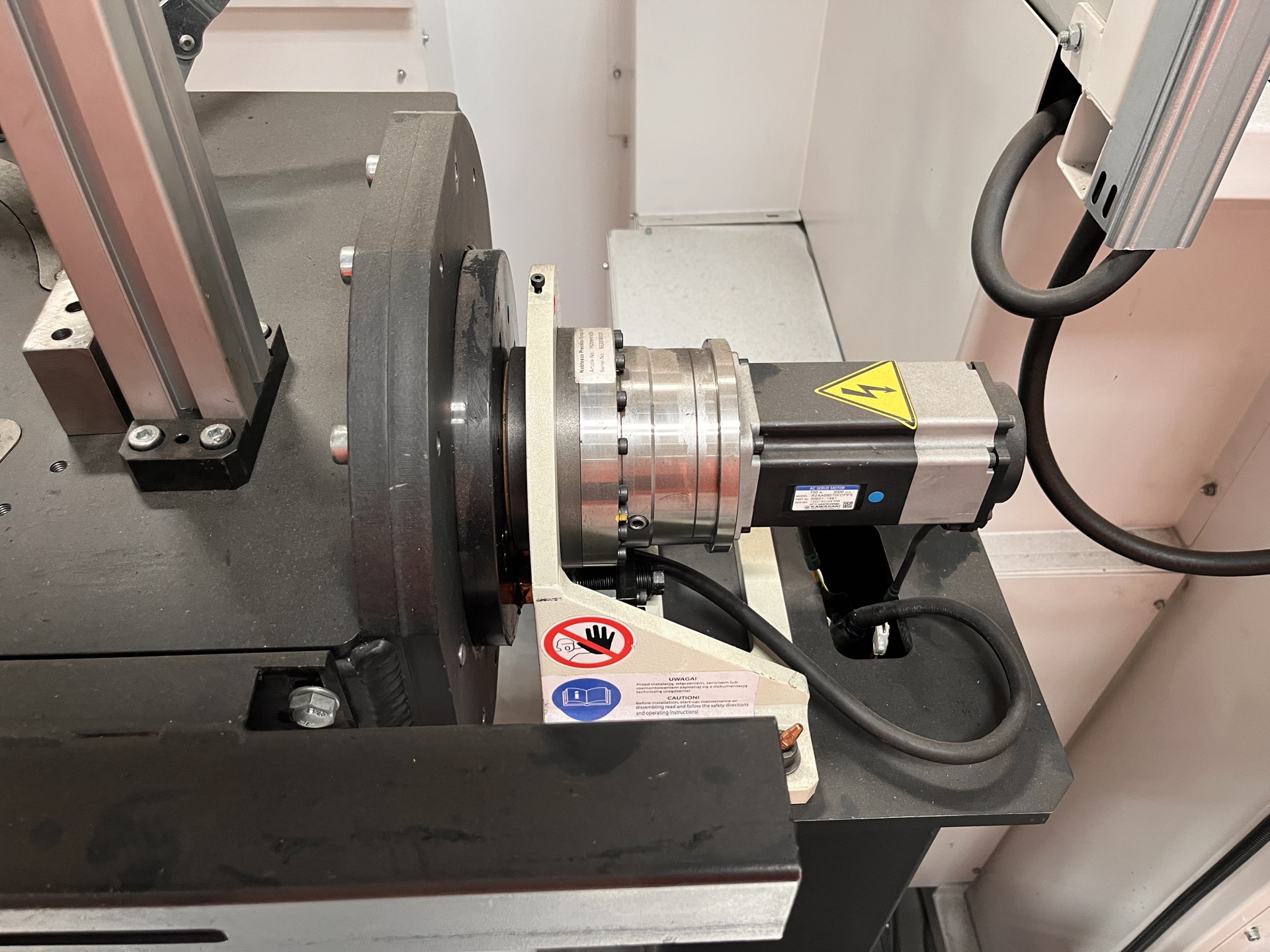

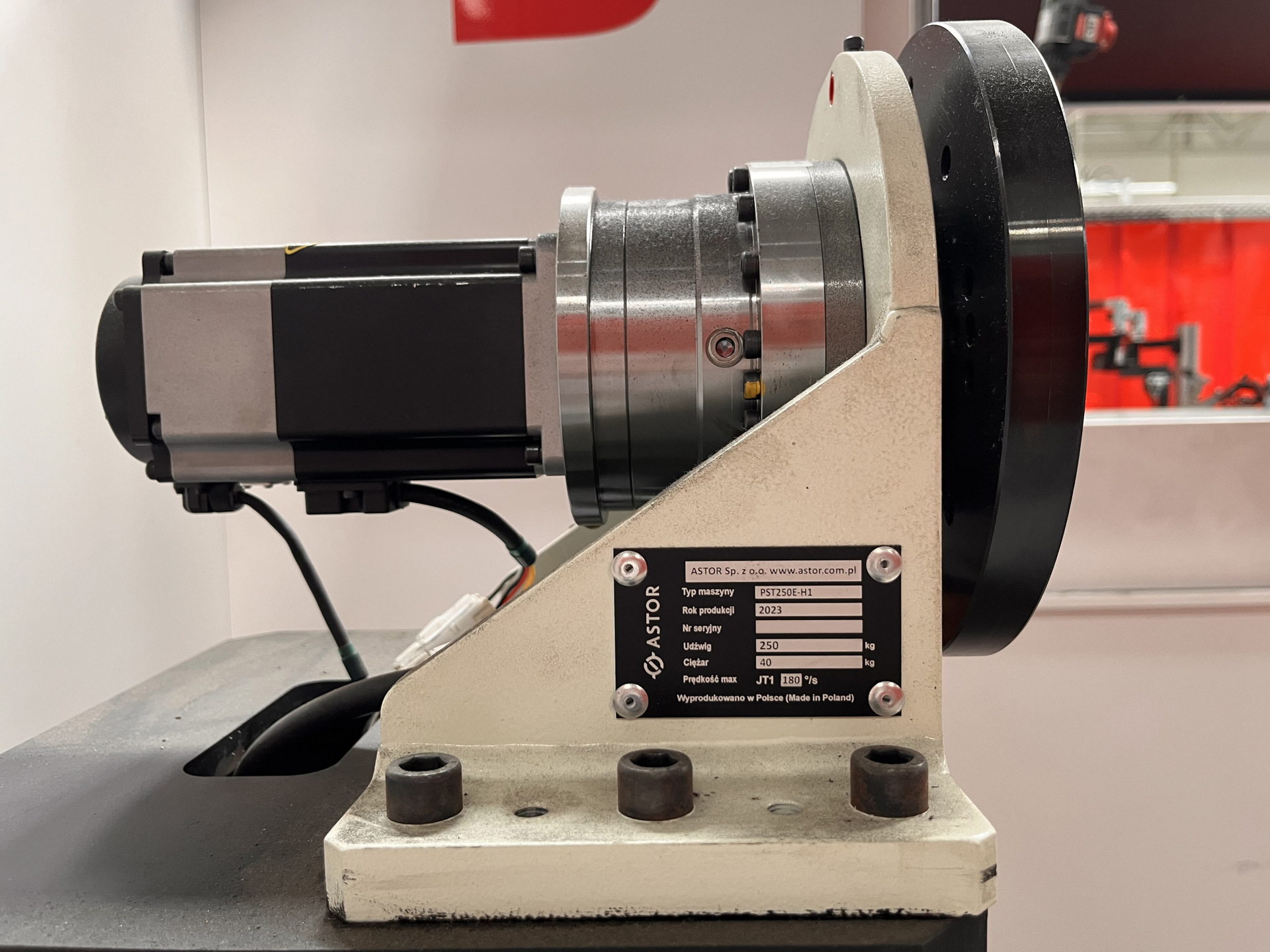

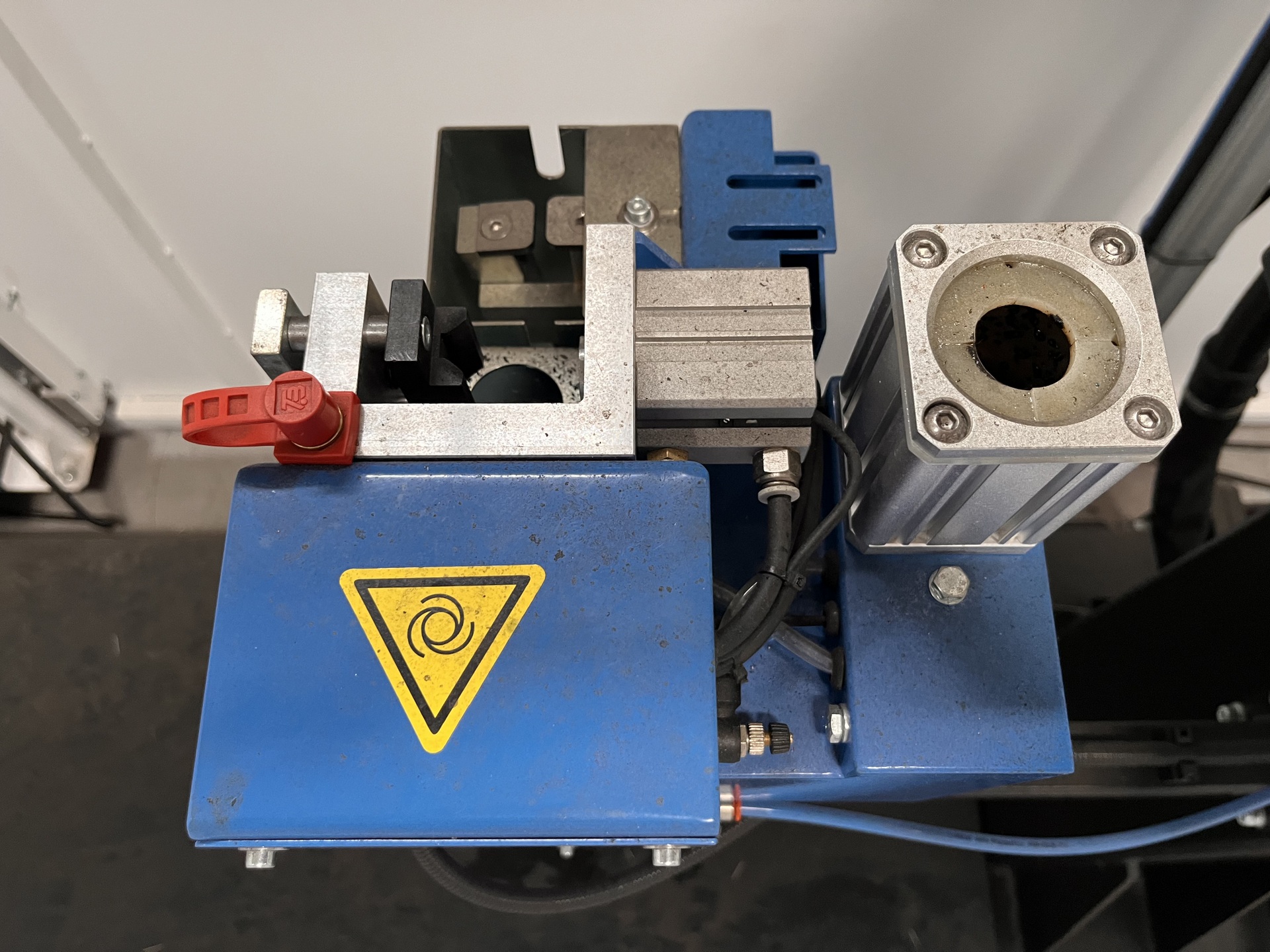

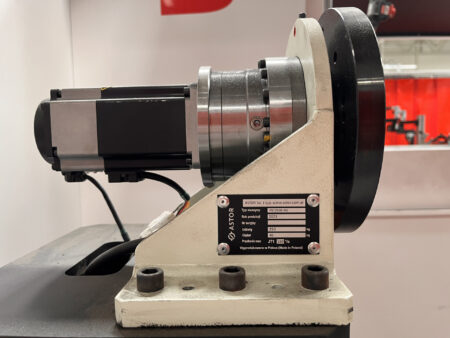

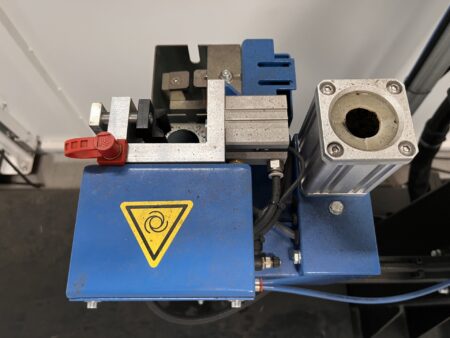

– welding positioner: ASTOR PST250E-H1 (2 pcs.)

– wire feeder

– cooling unit: FRONIUS CU

– welding fume extraction unit: KEMPER FilterCell XL (2 pcs.)

– fixed covers with safety switch

Technical specifications of the individual parts of the welding station KAWASAKI BA006L-A

Welding robot

- number of axes: 6

- maximum payload: 6 kg

- maximum arm reach: 2036 mm

- axis movement range

- axis motion speed

- positioning repeatability: ± 0.08 mm

- mounting: floor, ceiling

- ambient temperature: 0-45°C

- relative humidity: 35-85%

- weight: 160 kg

– JT1 axis: ± 165°

– JT2 axis: + 150° / -90°

– JT3 axis: + 90° / -175°

– JT4 axis: ± 180°

– JT5 axis: ± 135°

– JT6 axis: ± 360°

– JT1 axis: 210°/s

– JT2 axis: 210°/s

– JT3 axis: 220°/s

– JT4 axis: 430°/s

– JT5 axis: 430°/s

– JT6 axis: 650°/s

Welding positioner

- maximum payload: 250 kg

- number of axes: 1

- axis movement range: ± 360°

- maximum axis rotation speed: 180°/s

- axis height: 131 mm

- maximum distance from centre of gravity to axis: 105 mm

- positioning repeatability: ± 0.05 mm

- maximum bearing bending moment: 784 Nm

- maximum torque: 612 Nm

- nominal torque: 245 Nm

- maximum moment of inertia: 41 kgm2

- ambient temperature: 0-40°C

- weight: 40 kg

MIG/MAG welder

- mains voltage: 3x 400 V

- mains frequency: 50-60 Hz

- maximum welding current: 400 A

- minimum welding current: 3 A

- welding current at 40°C (40%/60%/100%): 400/360/320 A

- idle voltage: 75 V

- MIG/MAG operating voltage: 14.2-34 V

- touchscreen display with personalised menu in more than 30 languages

- water cooling

- degree of protection: IP23

- dimensions (L x W x H): 706 x 300 x 510 mm

Extraction unit

- capacity: 1000 m3/h

- maximum compressed air pressure: 6 bar

- minimum compressed air pressure: 5 bar

- power supply: 3x 400 V; 50 Hz

- weight: 135 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe