KAWASAKI BA006L welding robot was built in 2018. Used in the arc welding process, the robot is able to guarantee high quality and precision welding thanks to its high positioning repeatability and stability. The robustly constructed arm with a reach of 2036 mm performs 6-axis machining on workpieces with a maximum weight of 6 kg.

Easy arrangement and low wear of cables and hoses placed around the torch are ensured by the special design of the KAWASAKI BA Series machine with a pass-through wrist. Along with the industrial robot, equipment consisting of a KAWASAKI E01 controller, a FORNIUS TPS 400i welding machine and a cleaning station is offered. The KAWASAKI 3BA006L-AC01 articulated robot has undergone regular servicing during its lifetime. The total weight of the arc welding robot is 160 kg.

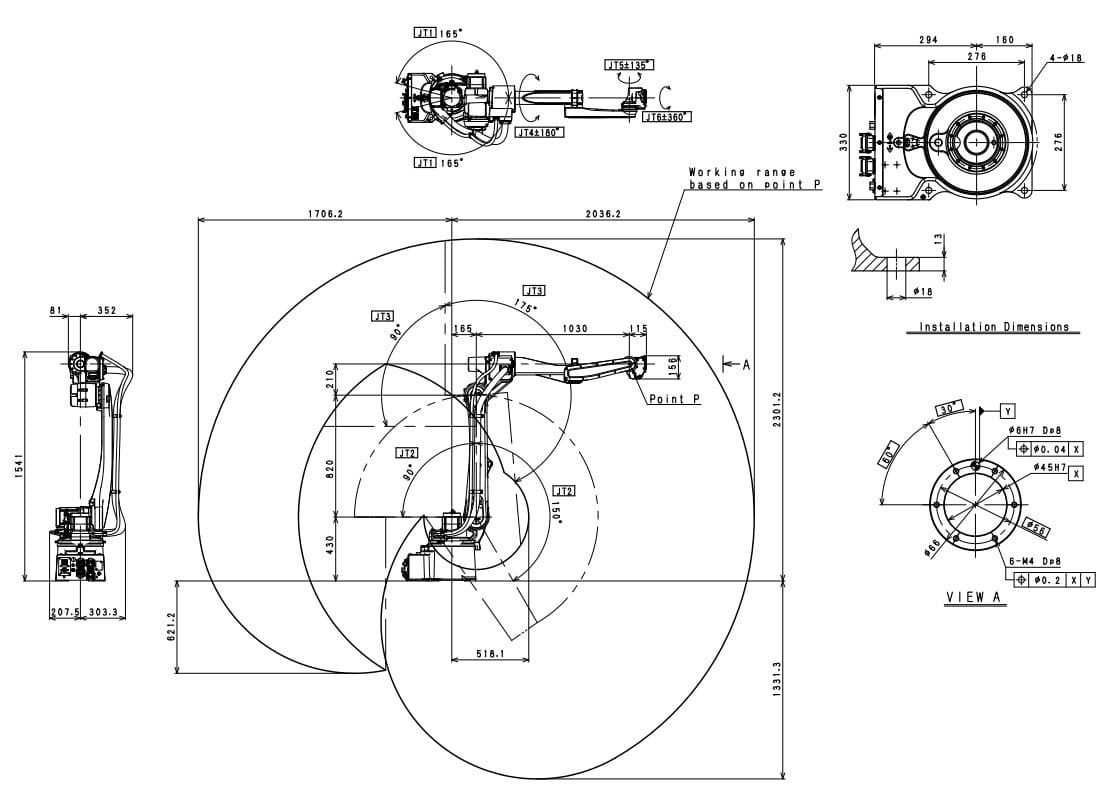

Specifications of the KAWASAKI BA006L industrial robot

- number of axes: 6

- maximum arm reach: 2036 mm

- maximum payload: 6 kg

- machine axis movement range

- machine axis motion range

- positioning repeatability: ±0.08 mm

- mounting: floor, ceiling

- ambient temperature: 0-45°

- controller weight: 40 kg

- machine weight: 160 kg

JT1 axis: ±165°

JT2 axis: +150° / -90°

JT3 axis: +90° / -175°

JT4 axis: ±180°

JT5 axis: ±135°

JT6 axis: ±360°

JT1 axis: 210°/s

JT2 axis: 210°/s

JT3 axis: 220°/s

JT4 axis: 430°/s

JT5 axis: 430°/s

JT6 axis: 650°/s

Equipment of the arc welding robot

- machine controller: KAWASAKI E01

- welding source: FORNIUS TPS 400i

- cleaning station

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe