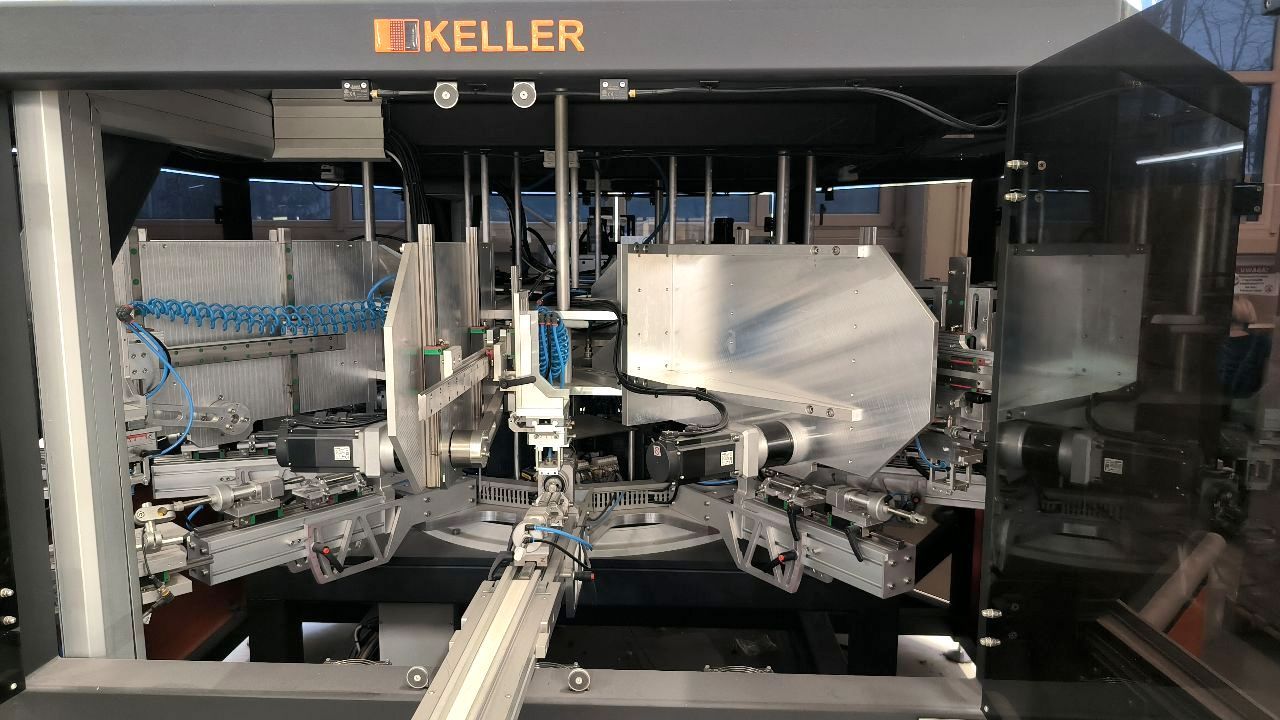

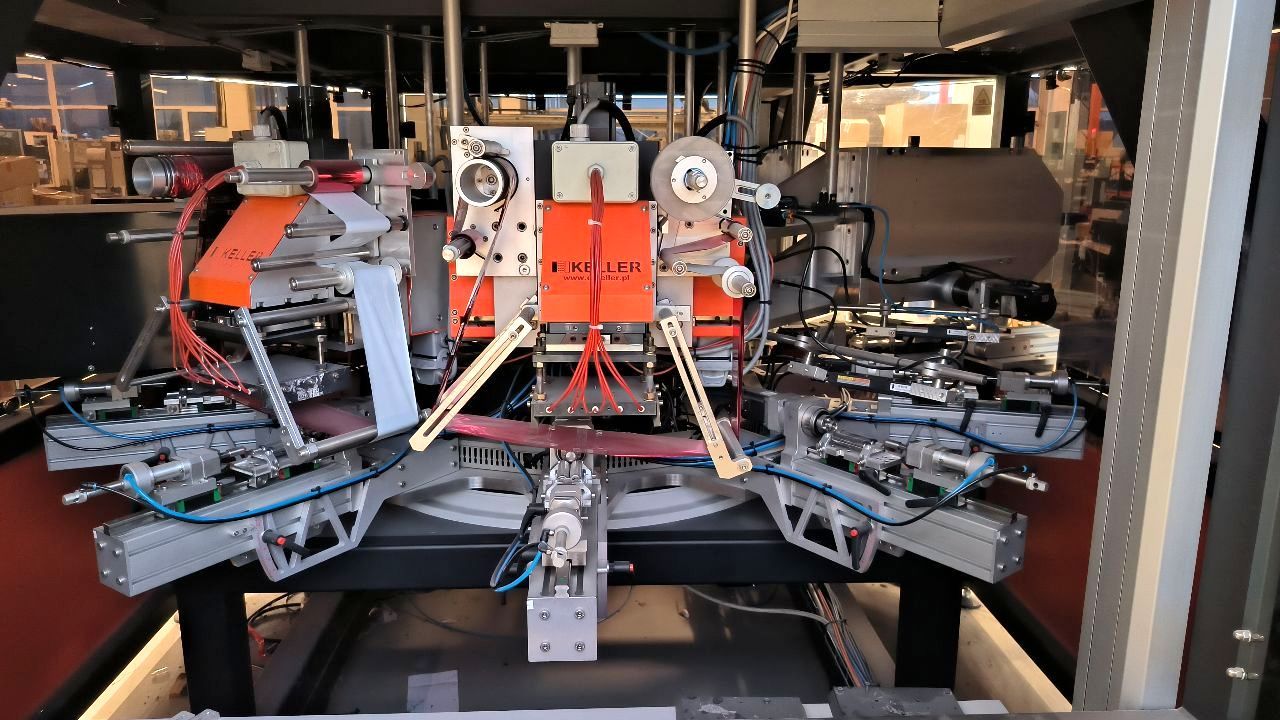

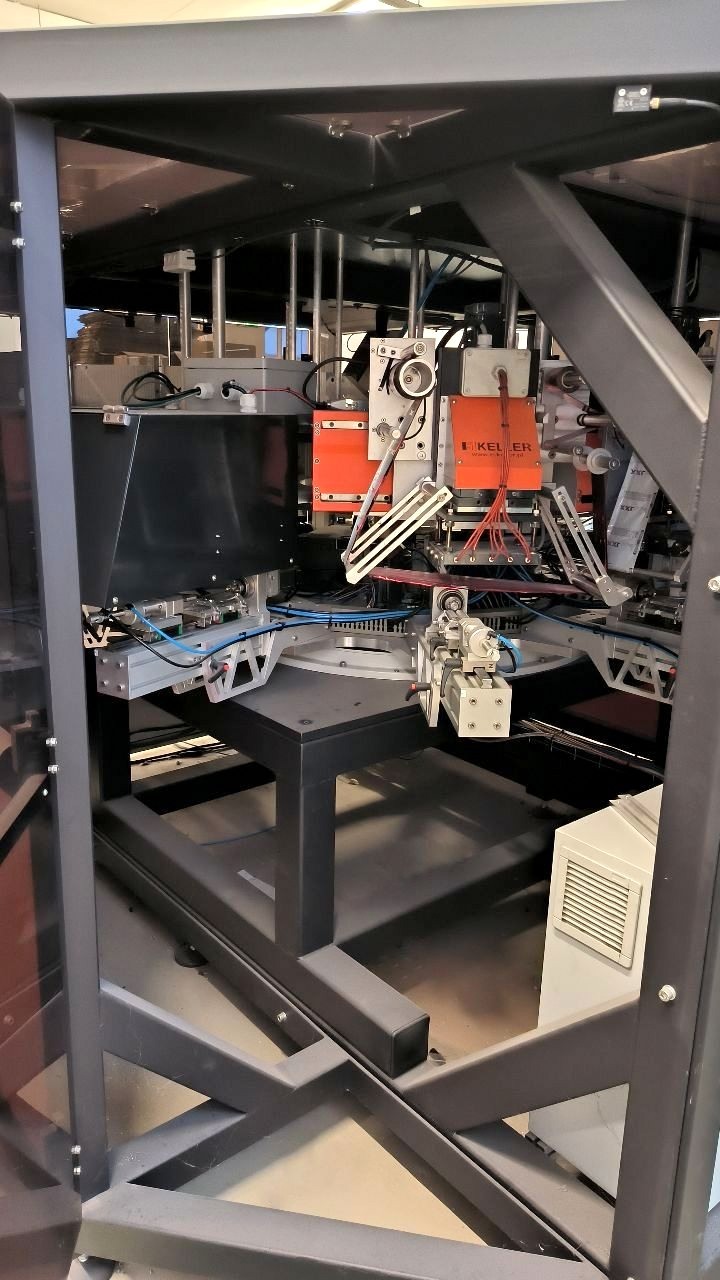

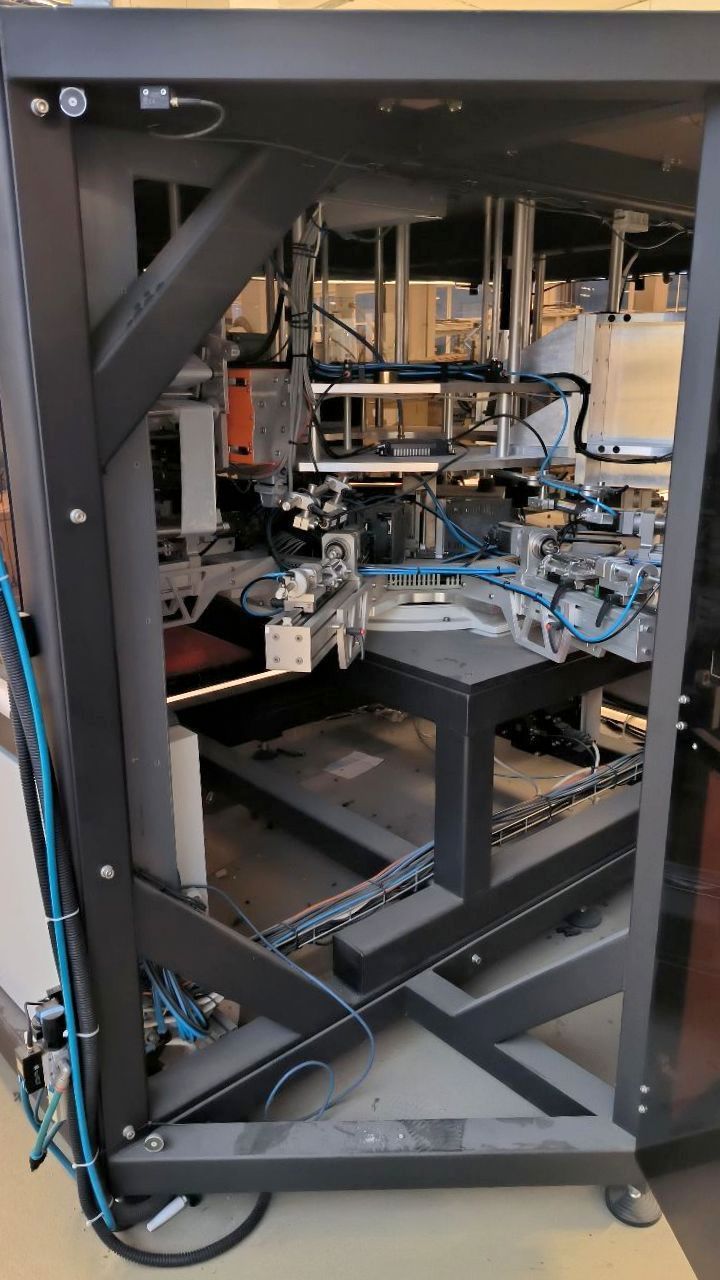

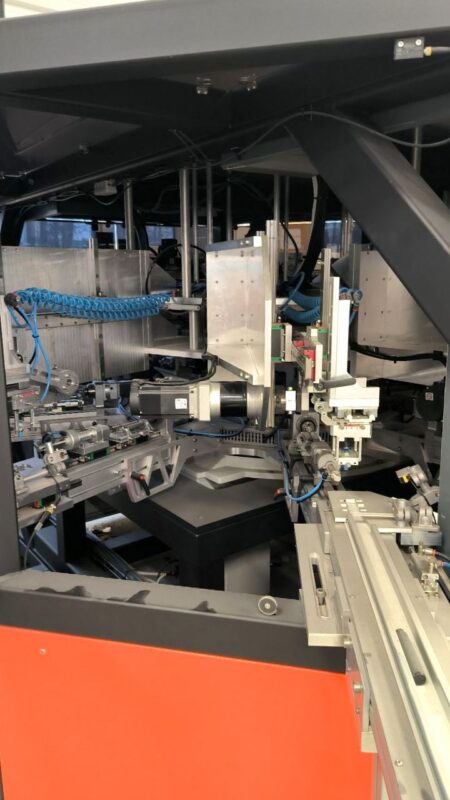

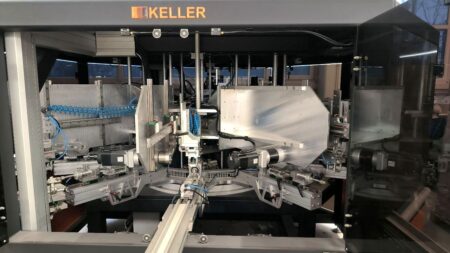

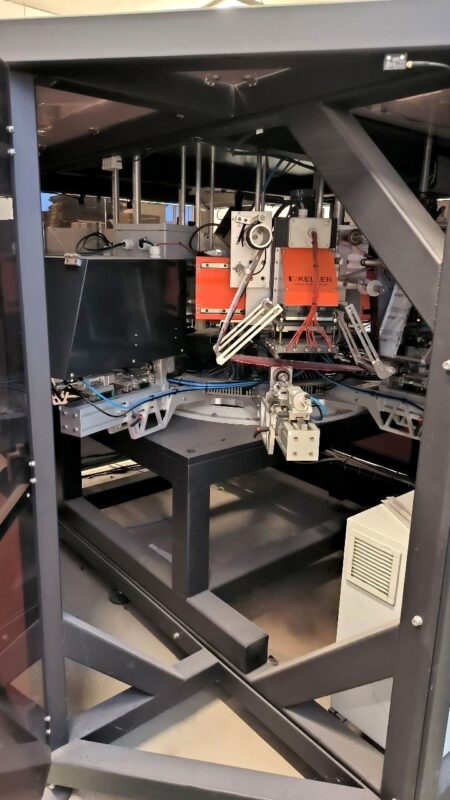

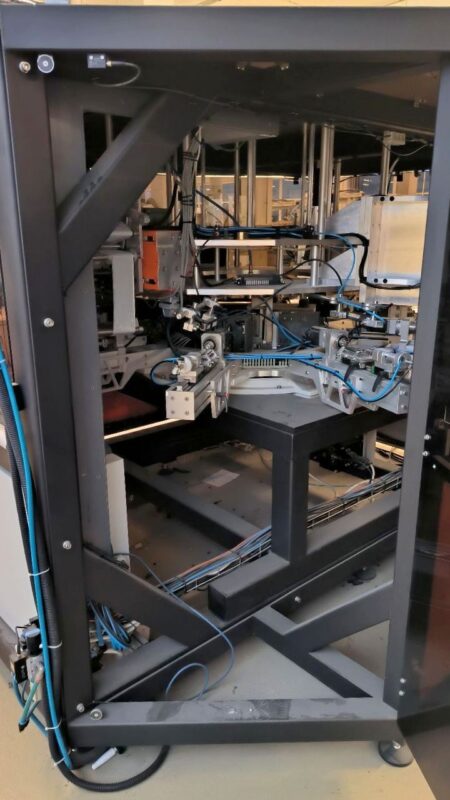

KELLER K-Roll ROTO 2 hot foil stamping machine was built in 2018 in Poland by KELLER poligrafia dla przemysłu Sp. z o. o. Sp. K. The machine is used in the printing industry for printing cylindrical parts by hot stamping. Hot stamping is a special printing method in which a special foil is transferred onto the material at high temperature and pressure. This results in gold- or silver-plated patterns, ideal for enhancing many products, such as business cards, diplomas or invitations.

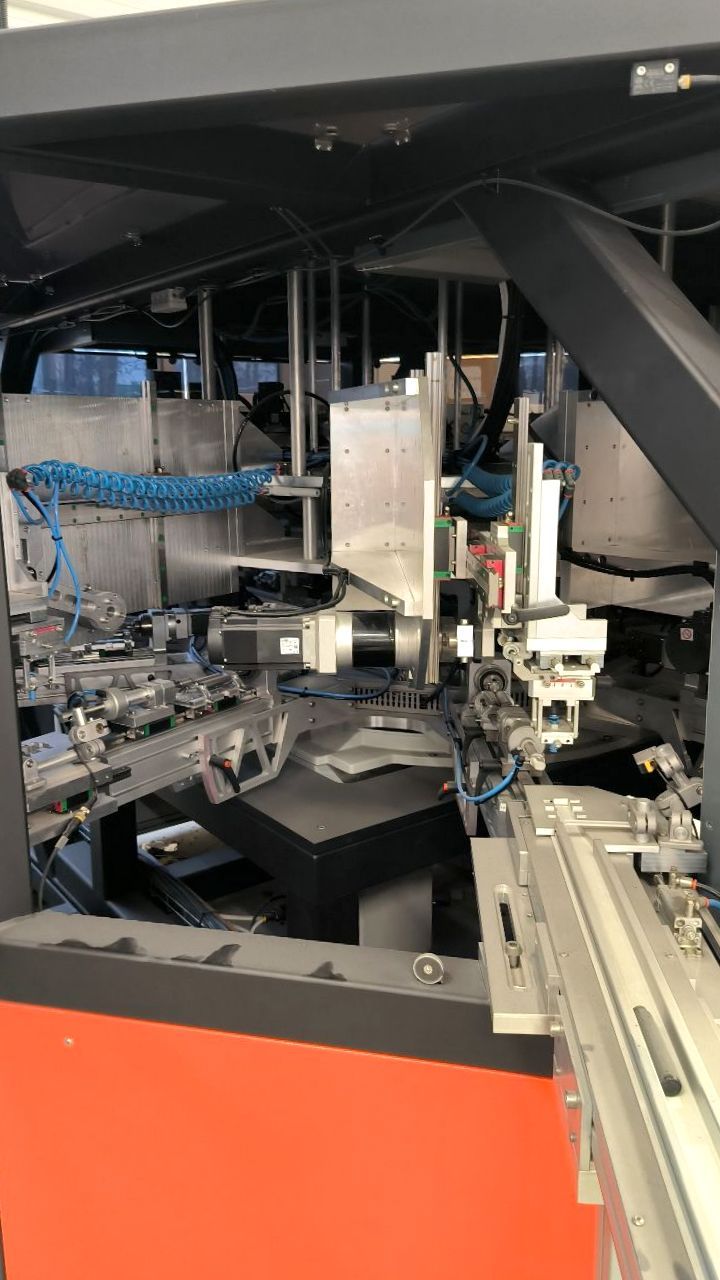

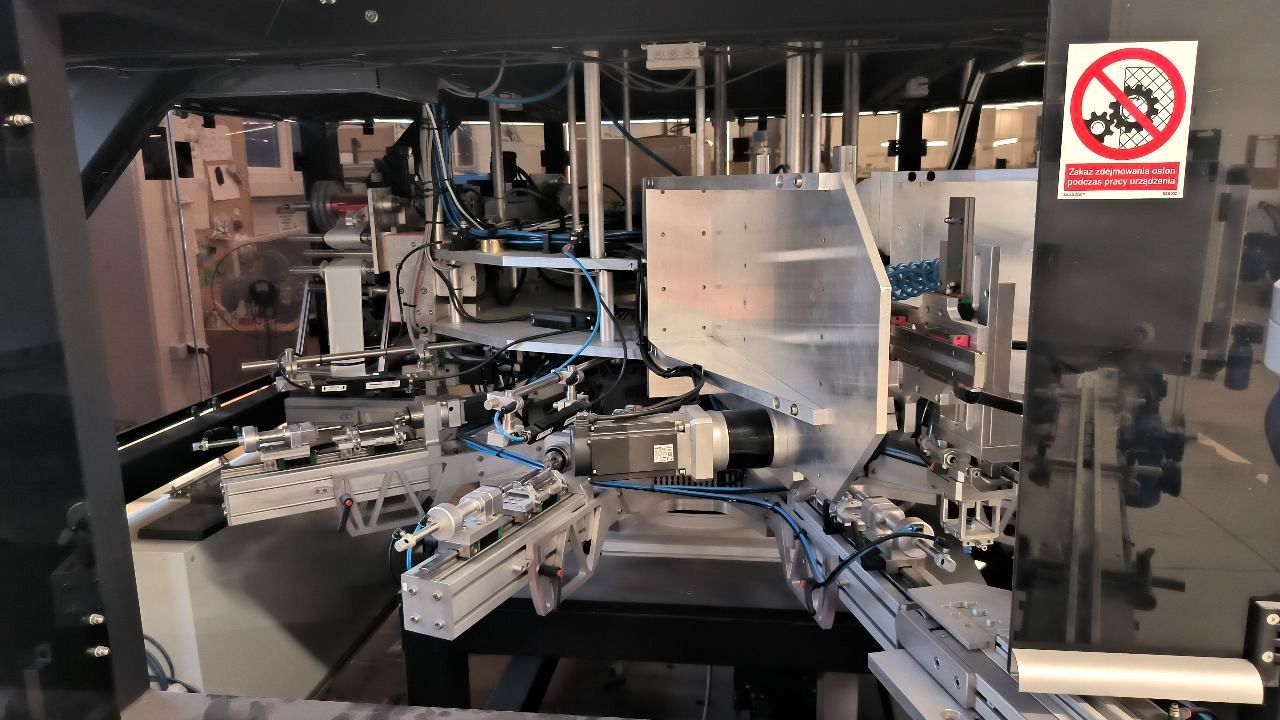

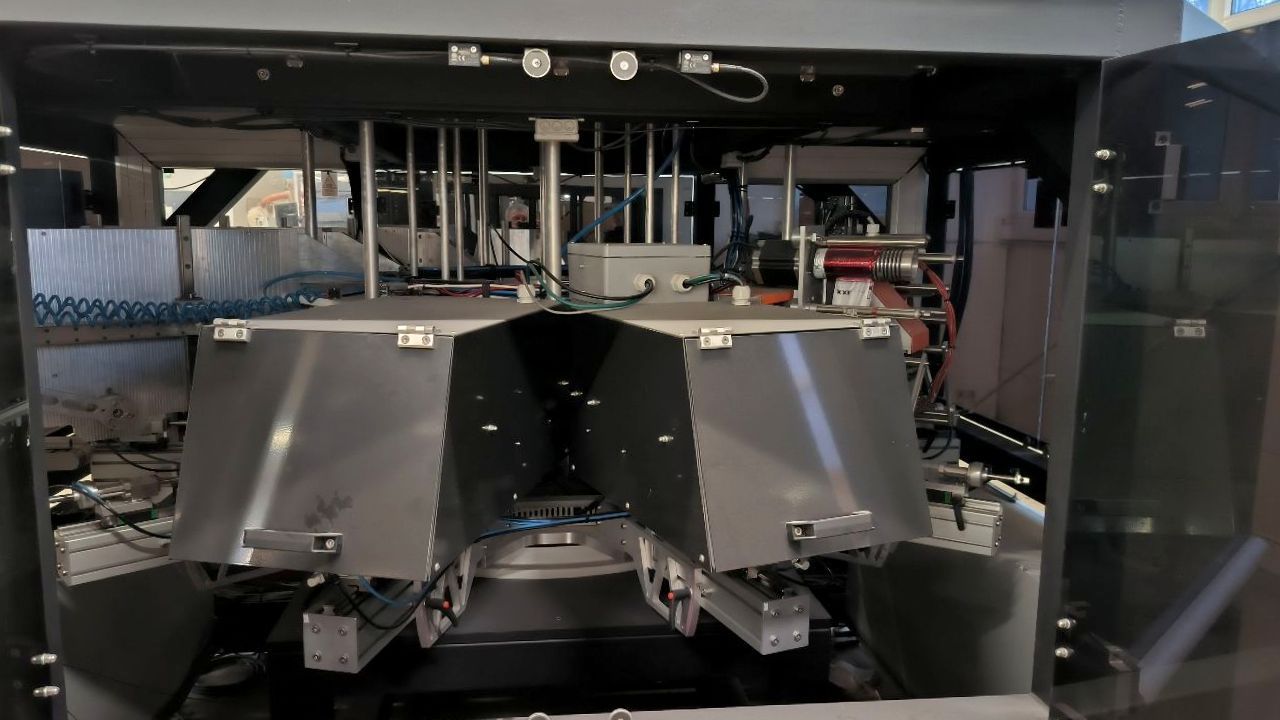

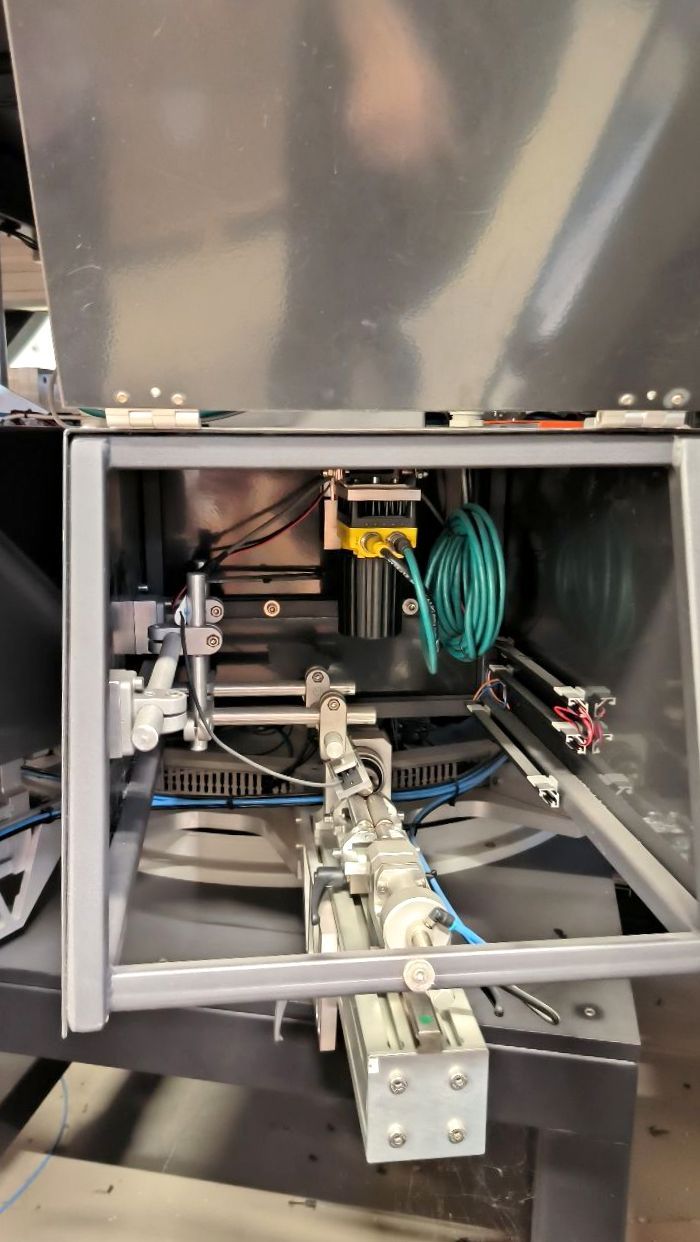

The KELLER K-Roll ROTO 2 performs the entire process fully automatically. Workpieces are fitted into the holders of the rotary table by means of conveyors and manipulators. The work table rotates two positions at a time, transferring them to the following de-ionisation and printing stations. At the end of the cycle, the parts are ready to be picked up on the outfeed conveyors or slide down the ramp into the collection containers.

The KELLER hot stamping machine is distinguished by the use of a range of modern components from renowned brands, which guarantee high efficiency over many years of intensive use. The offer also includes extensive equipment, consisting of, among others, a vision system, a remote access module and light curtains. The total weight of the machine is 1500 kg.

Technical specifications of the KELLER K-Roll ROTO 2 hot foil stamping machine

- MITSUBISHI control system with 10″ touch screen display

- maximum workpiece diameter: 30 mm

- maximum workpiece length: 150 mm

- number of printing stations: 2

- print speed (depending on project and workpiece): 2000 to 4000 pcs/h

- rotary index table: WEISS

- quick die mounting system

- automatic film feed system

- infeed and outfeed conveyors

- manipulators

- deionisation station with extraction

- light curtains: OMRON

- vision system: COGNEX

- remote access module

- security module: WIELAND

- servo drives: MITSUBISHI

- guide rails in all axes: HIWIN

- cartridge heaters with regulator: MITSUBISHI

- pneumatic system: FESTO + METALWORK

- DTR – Technical and Operating Documentation

- pneumatic system pressure: 6-8 bar

- power supply: 400 V

- dimensions (L x W x H): 4000 x 2500 x 2200 mm

- weight of the KELLER K-Roll ROTO 2 machine: 1500 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe