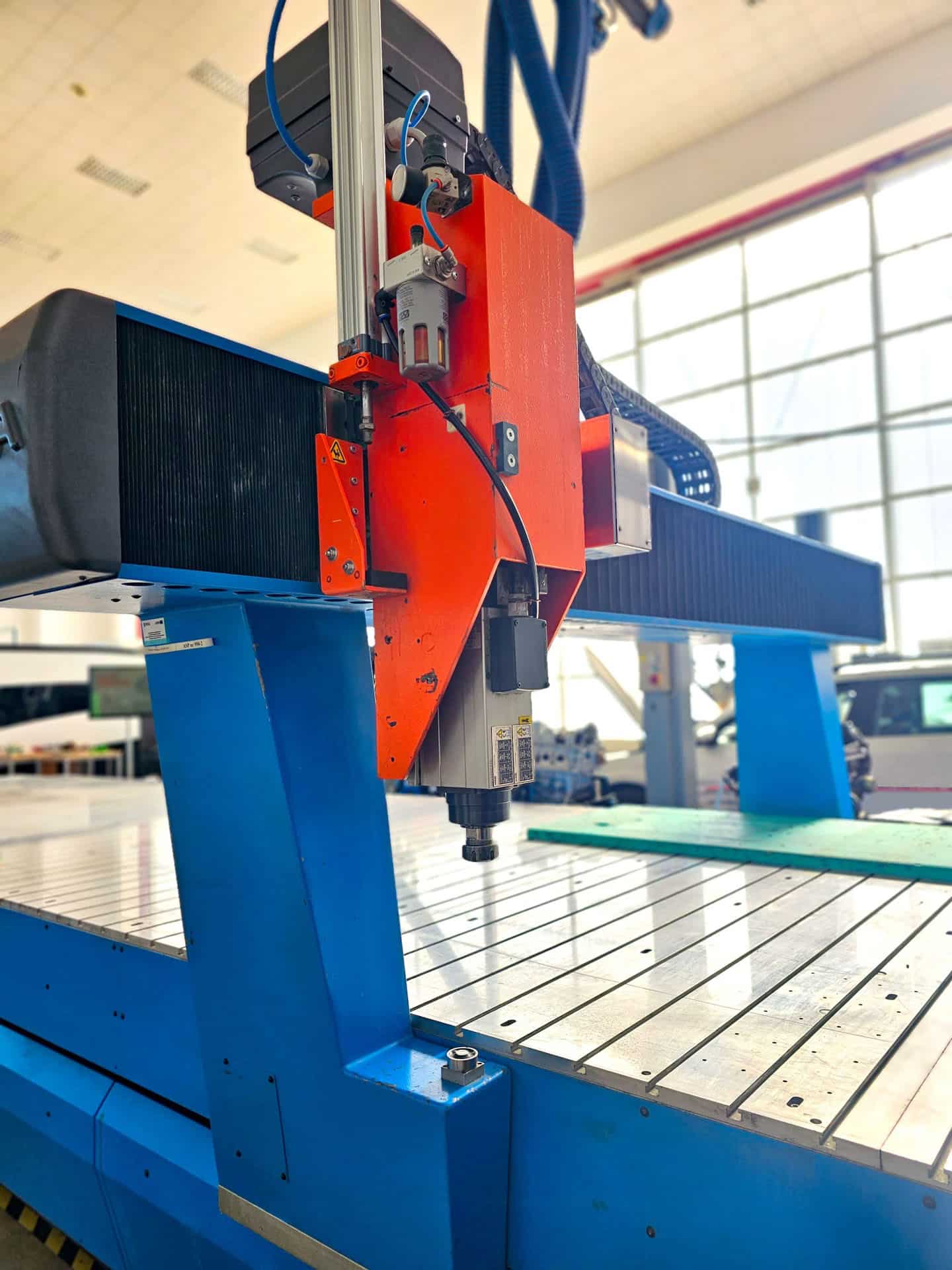

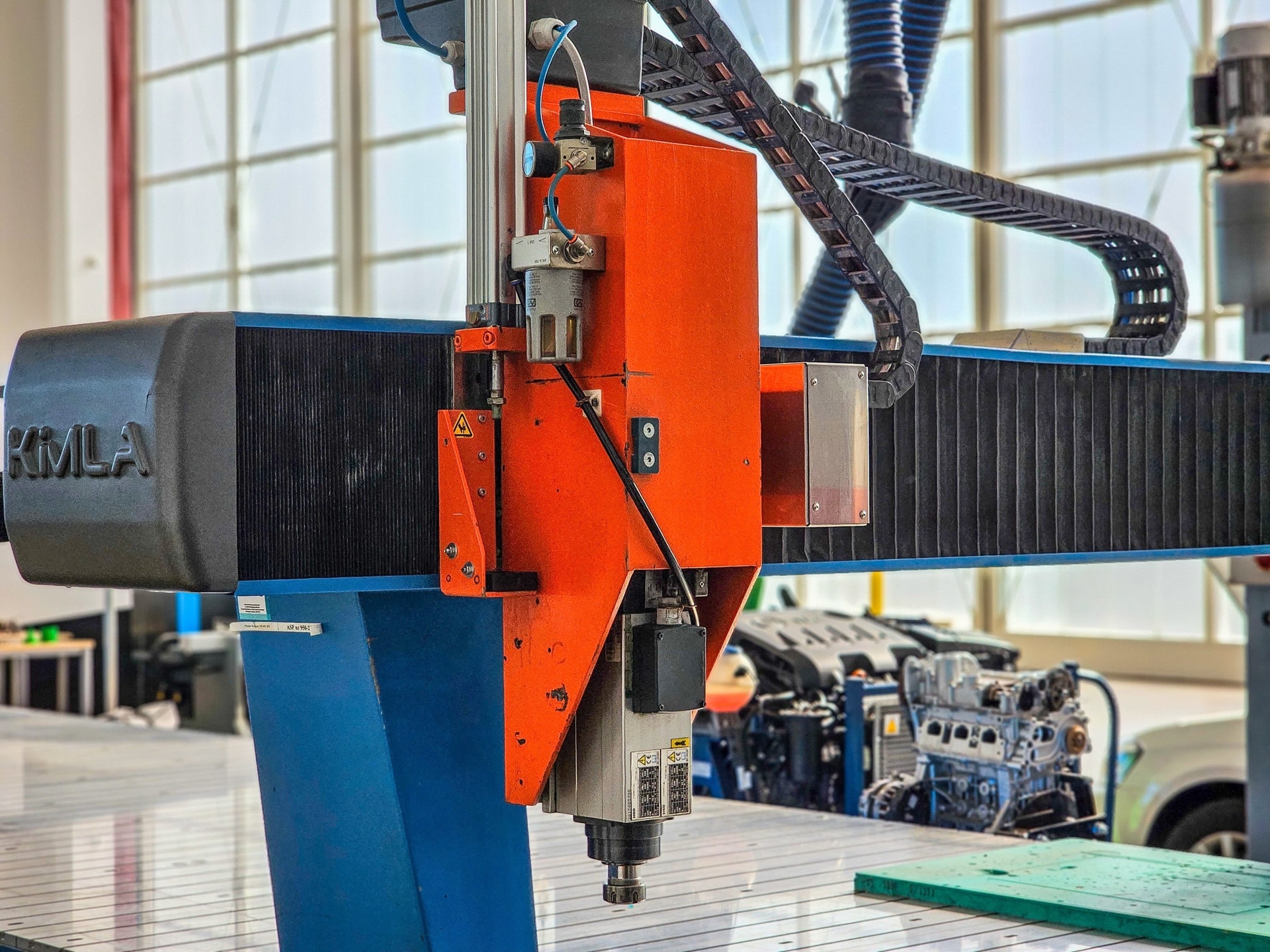

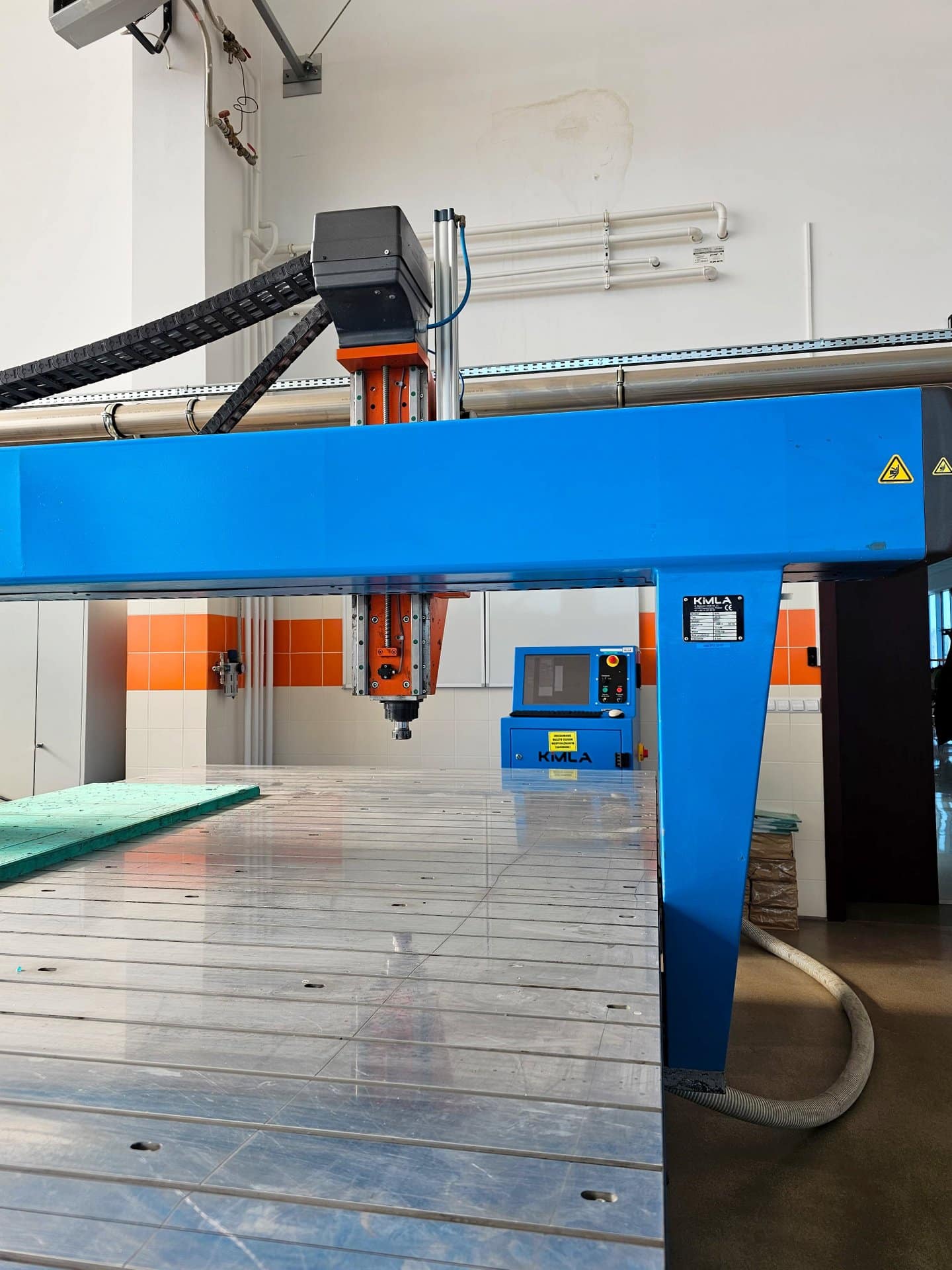

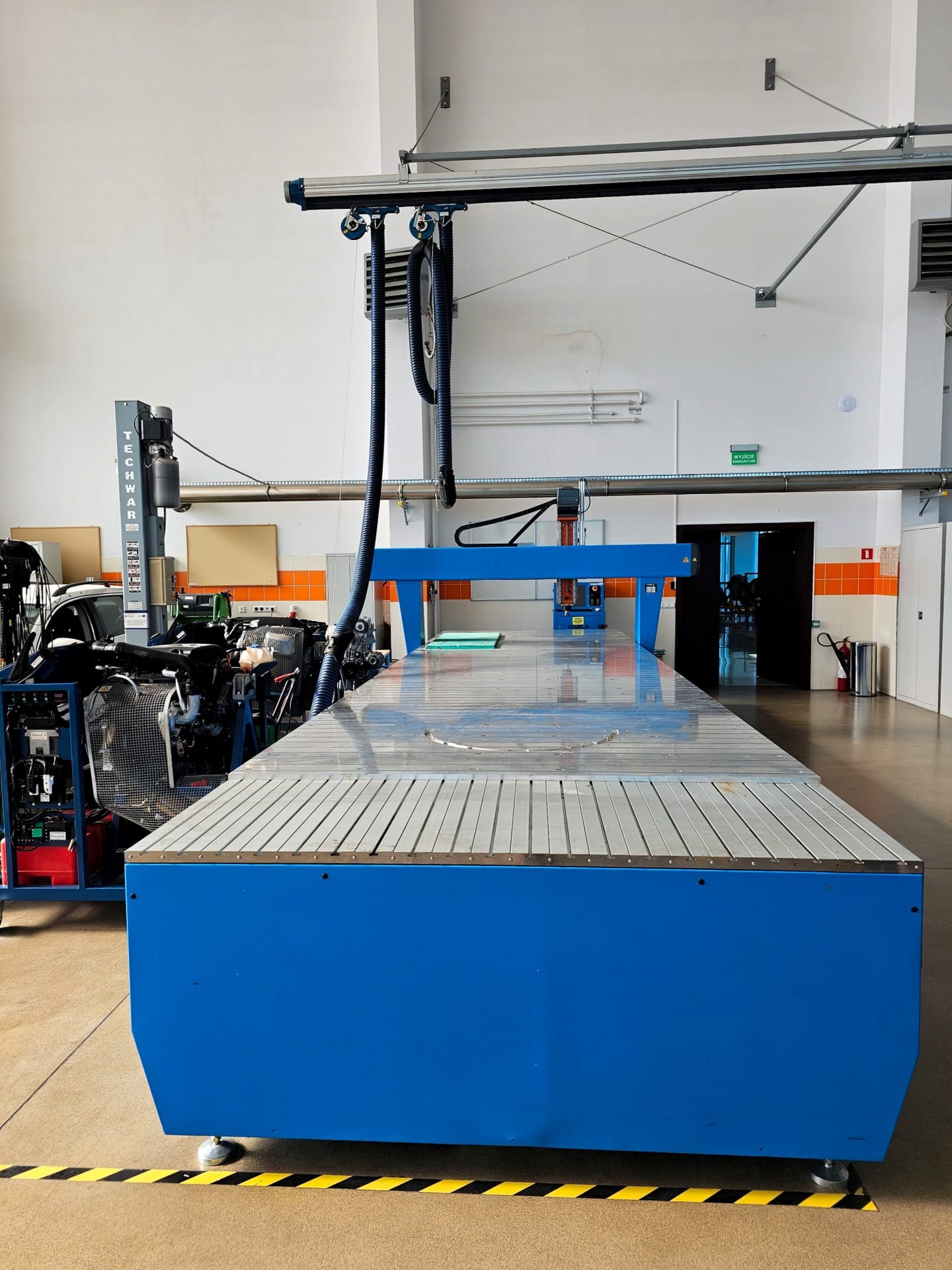

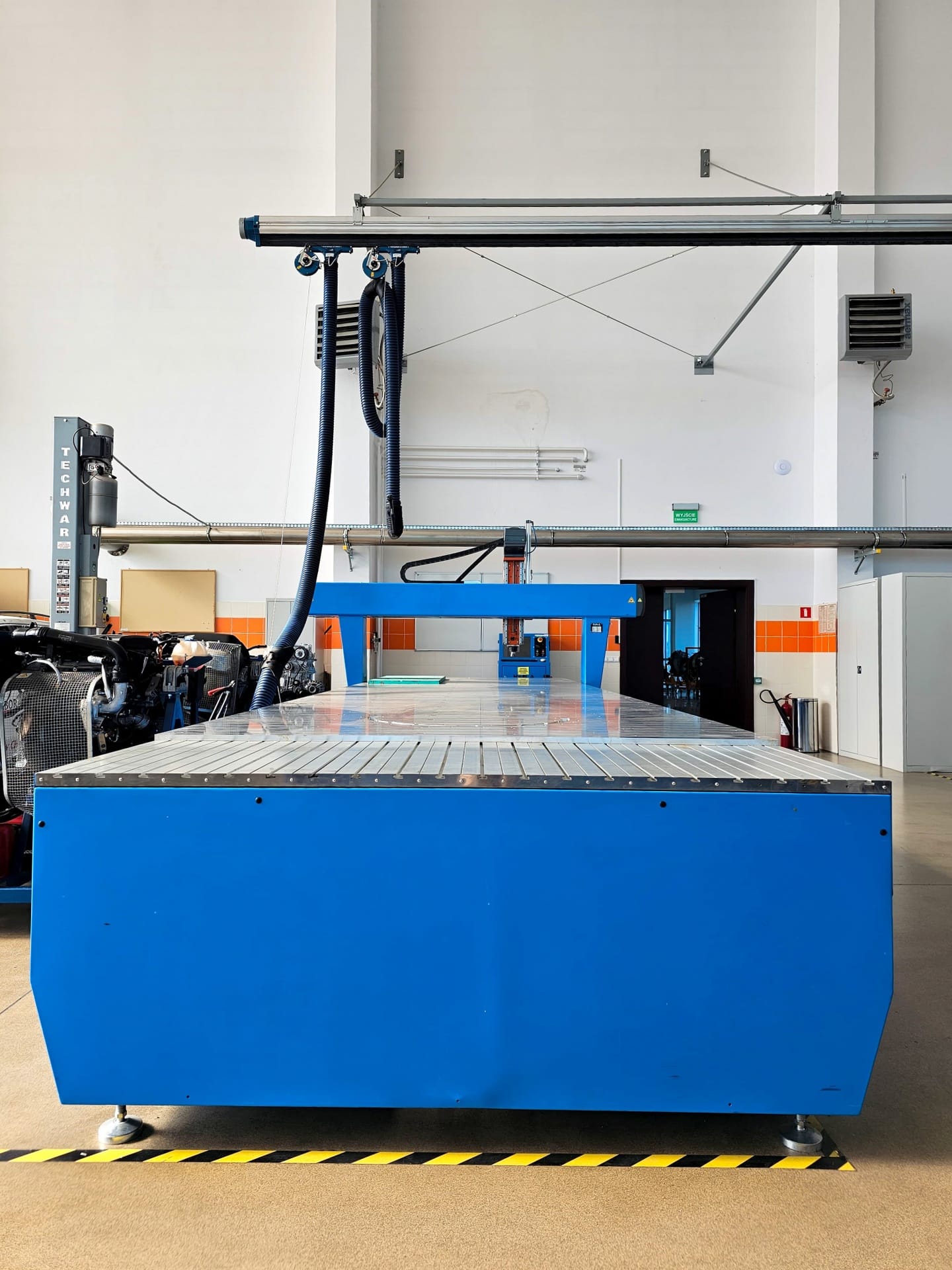

KIMLA BPF 2070 CNC router was built in 2010 in Poland by POLCOM Przemysław Kimla. The machine is used for precision machining of parts made of such materials as wood, plastics and aluminium. The machining process is performed on a large work table with a length of 7050 mm and a width of 2085 mm by means of a reliable, high-speed spindle. Process stability, on the other hand, is ensured by an extremely rigid design that effectively eliminates any vibration and oscillation during even the most intense challenges. All this is complemented by an industrial CNC controller with easy-to-use PC-CAM software. The BPF 2070 CNC milling machine weighs 6000 kg.

Technical specifications of the KIMLA BPF 2070 milling machine

- machinable materials: wood, plywood, polycarbonate, polymer plates, aluminium, etc.

- feed in the X/Y/Z axis: 2085/7050/500 mm

- work area (L x W): 7050 x 2085 mm

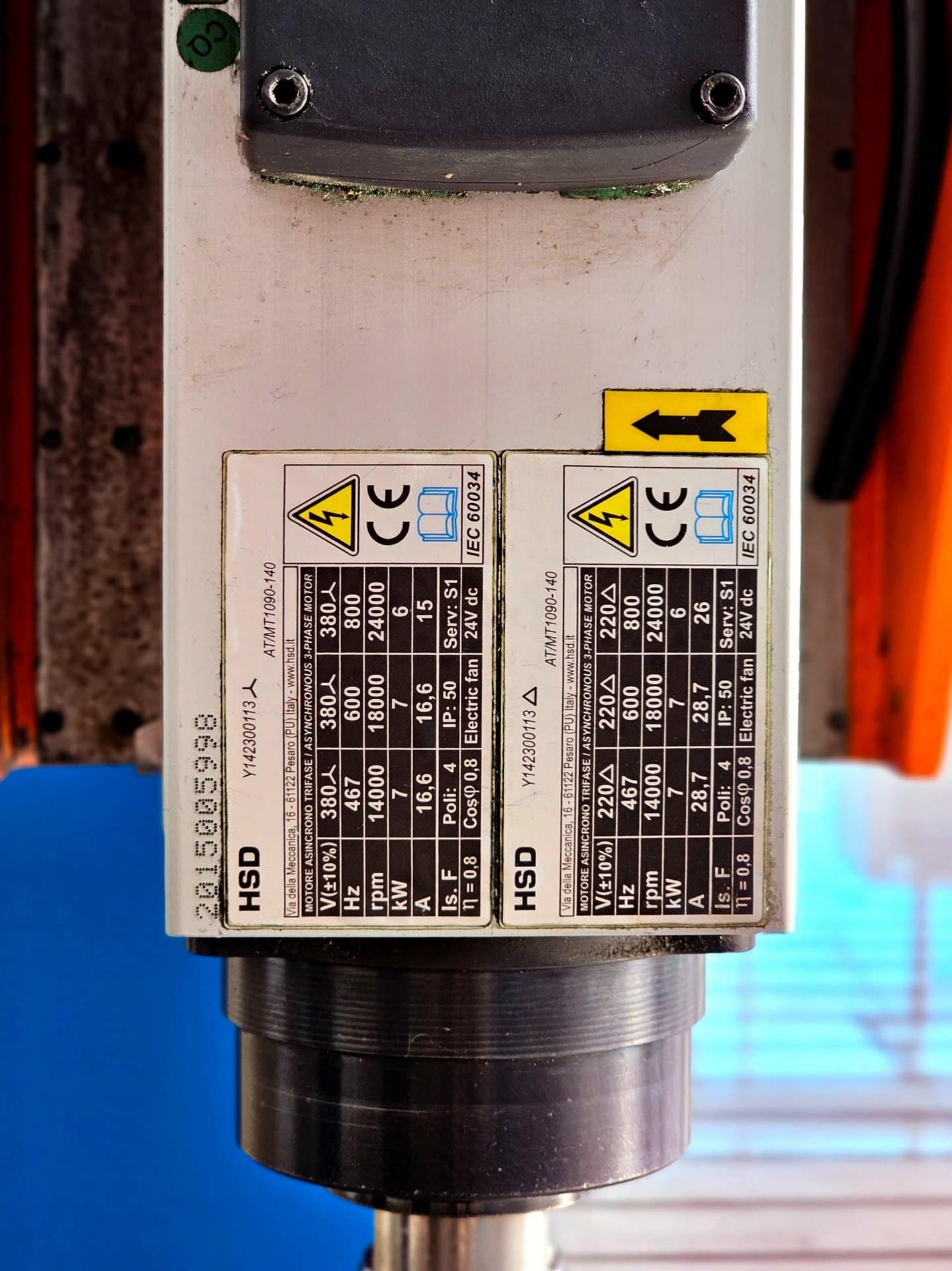

- maximum spindle rotational speed: 24000 rpm

- minimum spindle rotational speed: 2400 rpm

- spindle drive power: 7 kW

- tool change: manual

- gantry dimensions (W x H): 3160 x 2170 mm

- compressed air pressure: 8 bar

- total power: 13 kW

- power supply: 400 V; 50 Hz

- weight of the KIMLA BPF 2070 machine: 6000 kg

Equipment of the KIMLA CNC router

- industrial CNC controller

- software: PC-CAM

- spindle: ELTE 7 kW

- aluminium work table with T-slots

- ER32 collet

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe