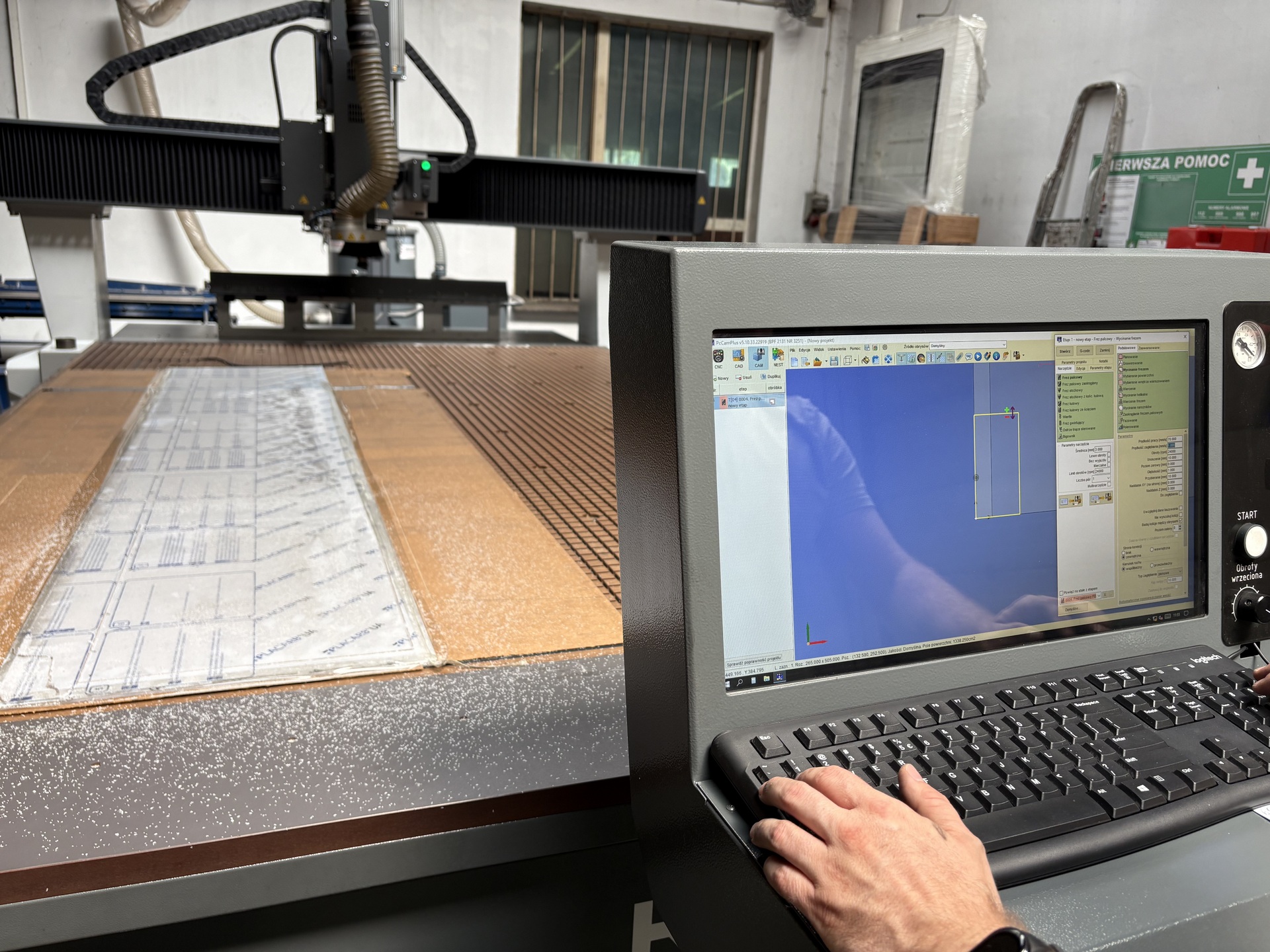

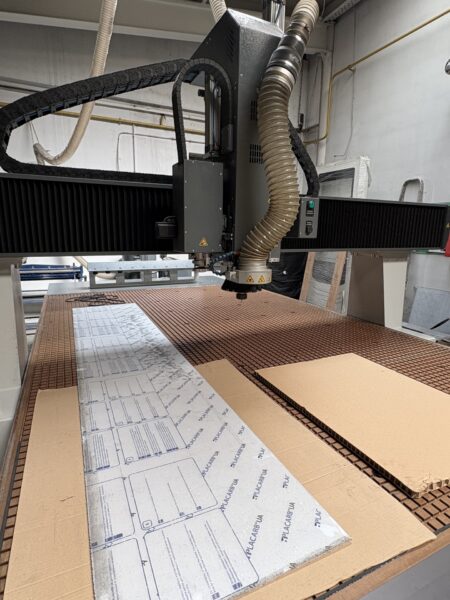

KIMLA BPF 2131 CNC router was built in 2020 in Poland by POLCOM Przemysław Kimla. The machine has only worked for 180 hours, it is like brand new.

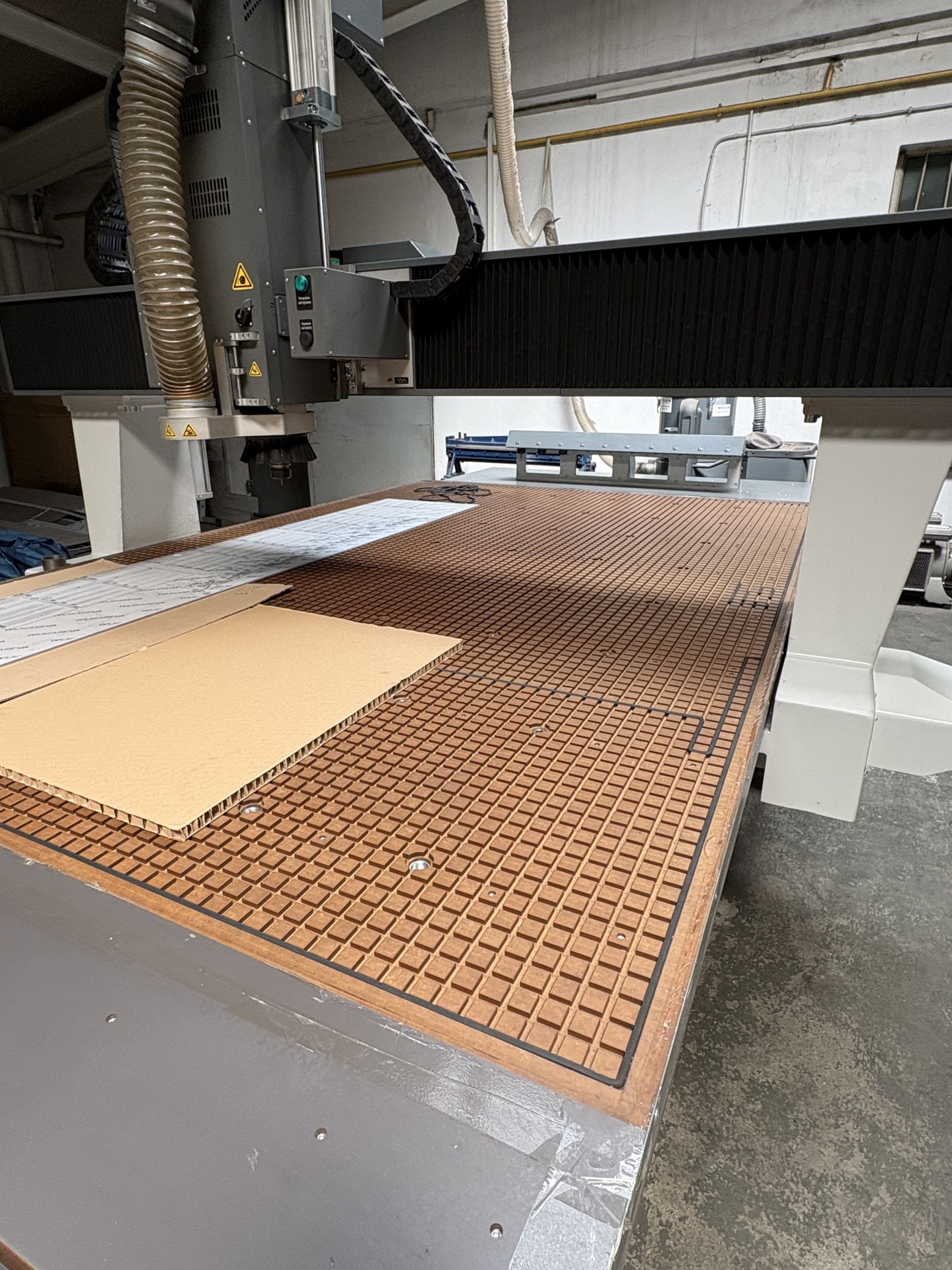

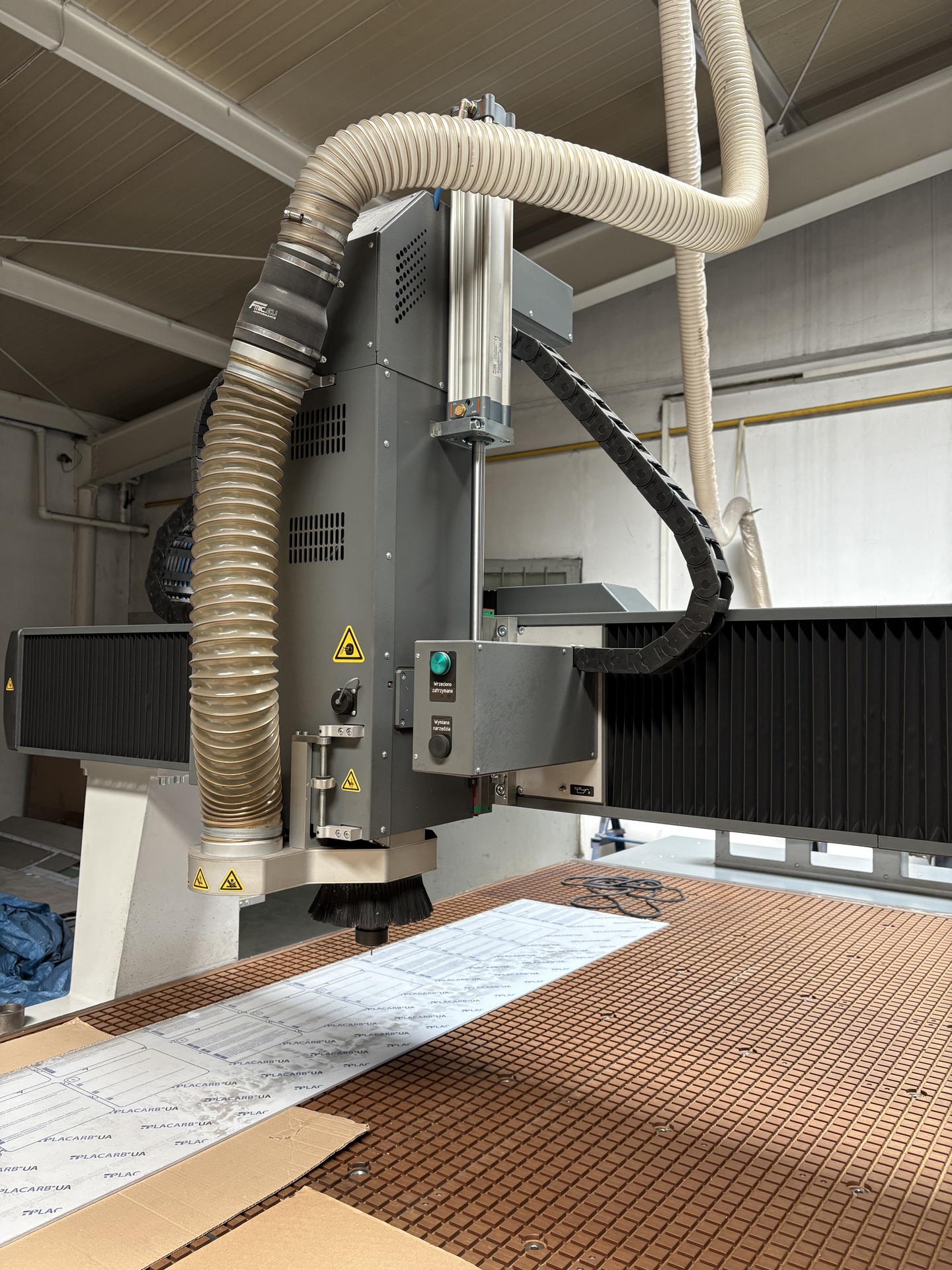

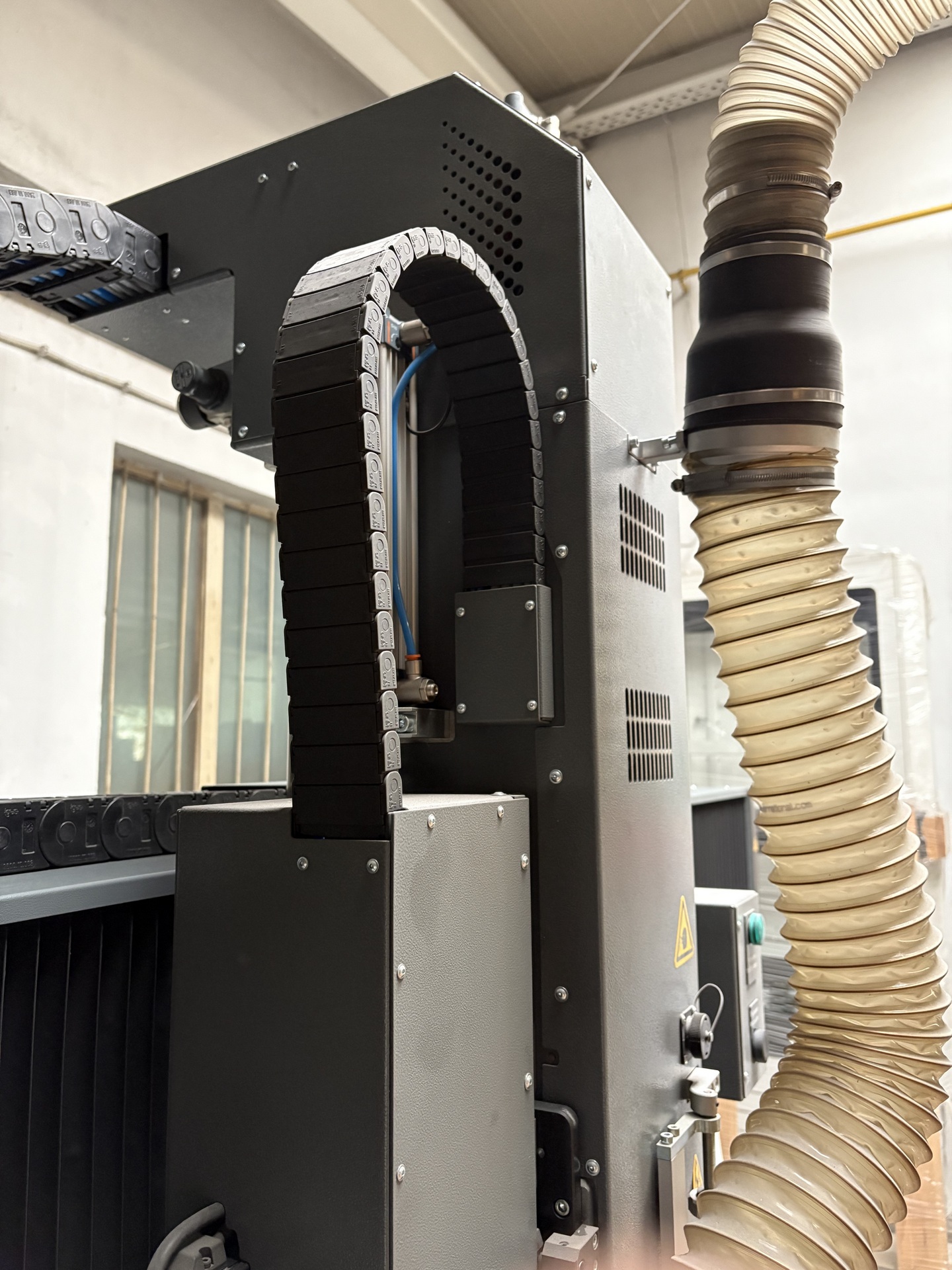

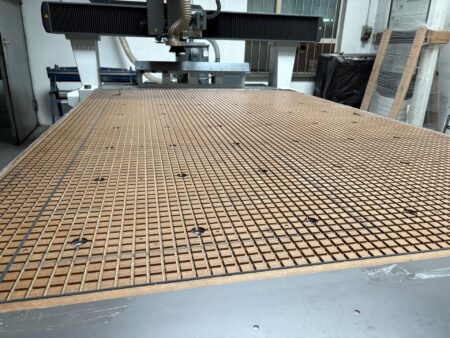

KIMLA BPF 2131 is designed for both small and medium-sized industrial plants with a diverse production profile. It allows precise machining of a wide range of materials, such as soft metals, wood and plastics. These workpieces are machined on a large vacuum table by means of a powerful spindle. The work table’s design enables separation of independent sections so that the work area can be adapted to the specific workpiece. All axes, in turn, are driven by high-performance digital AC servo drives, which guarantee excellent feed dynamics and precision during even the most intensive tasks. The BPF 2131 router is offered with an extensive range of equipment, consisting of, among others, an advanced control system and a vacuum pump. The total weight of the machine is 5000 kg.

Technical specifications of the KIMLA BPF 2131 CNC milling machine

- machinable materials: soft metals, wood, wood-based materials, plastics, etc.

- feed in the Z axis: 300 mm

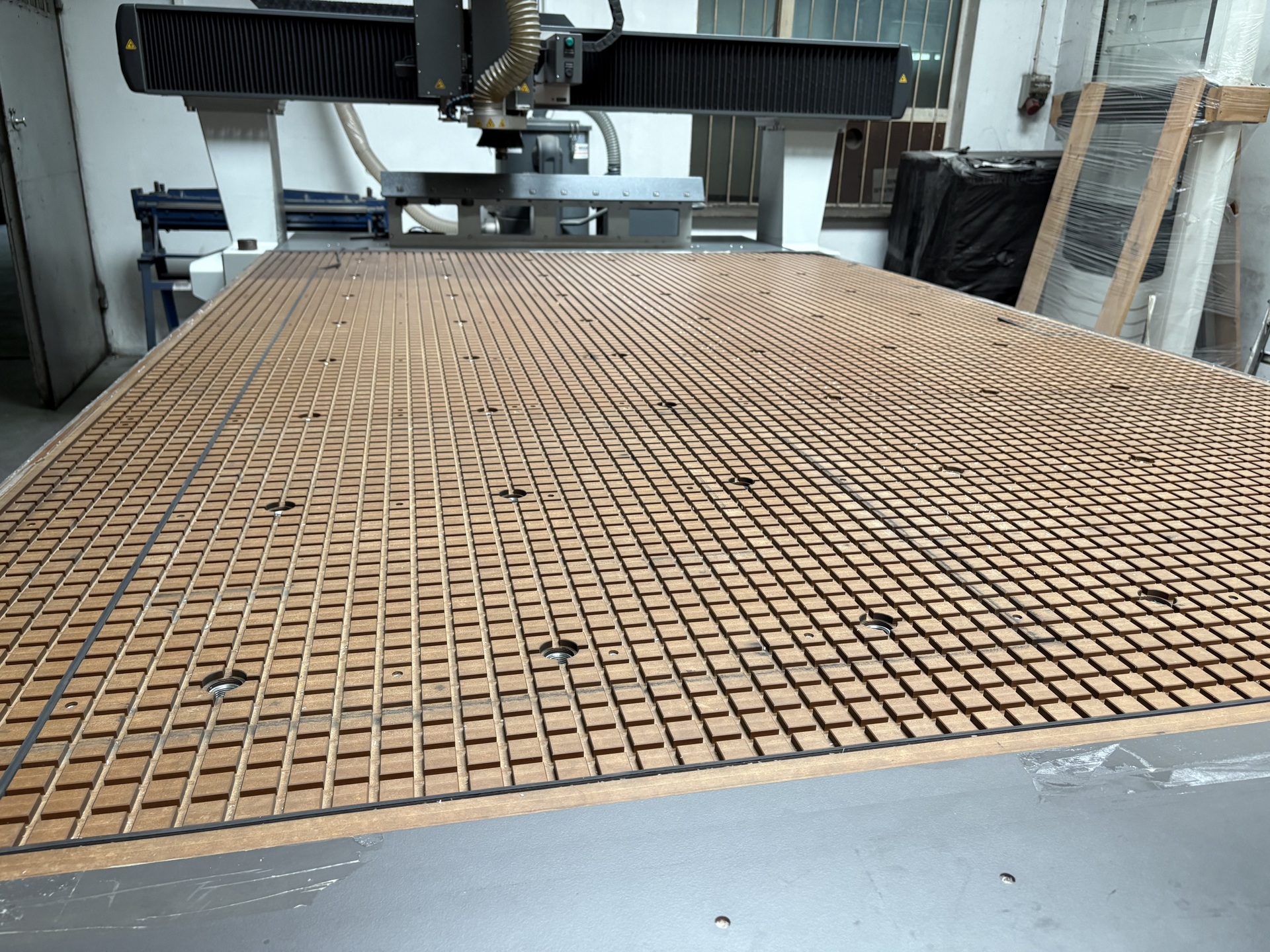

- work table dimensions (L x W): 3100 x 2100 mm

- maximum spindle rotational speed: 24000 rpm

- spindle taper: ISO 30

- spindle drive power: 9 kW

- operating hours: 180 h

- compressed air pressure: 8 bar

- total power: 12 kW

- power supply: 400 V; 50 Hz

- weight of the KIMLA BPF 2131 machine: 5000 kg

Equipment of the KIMLA milling machine

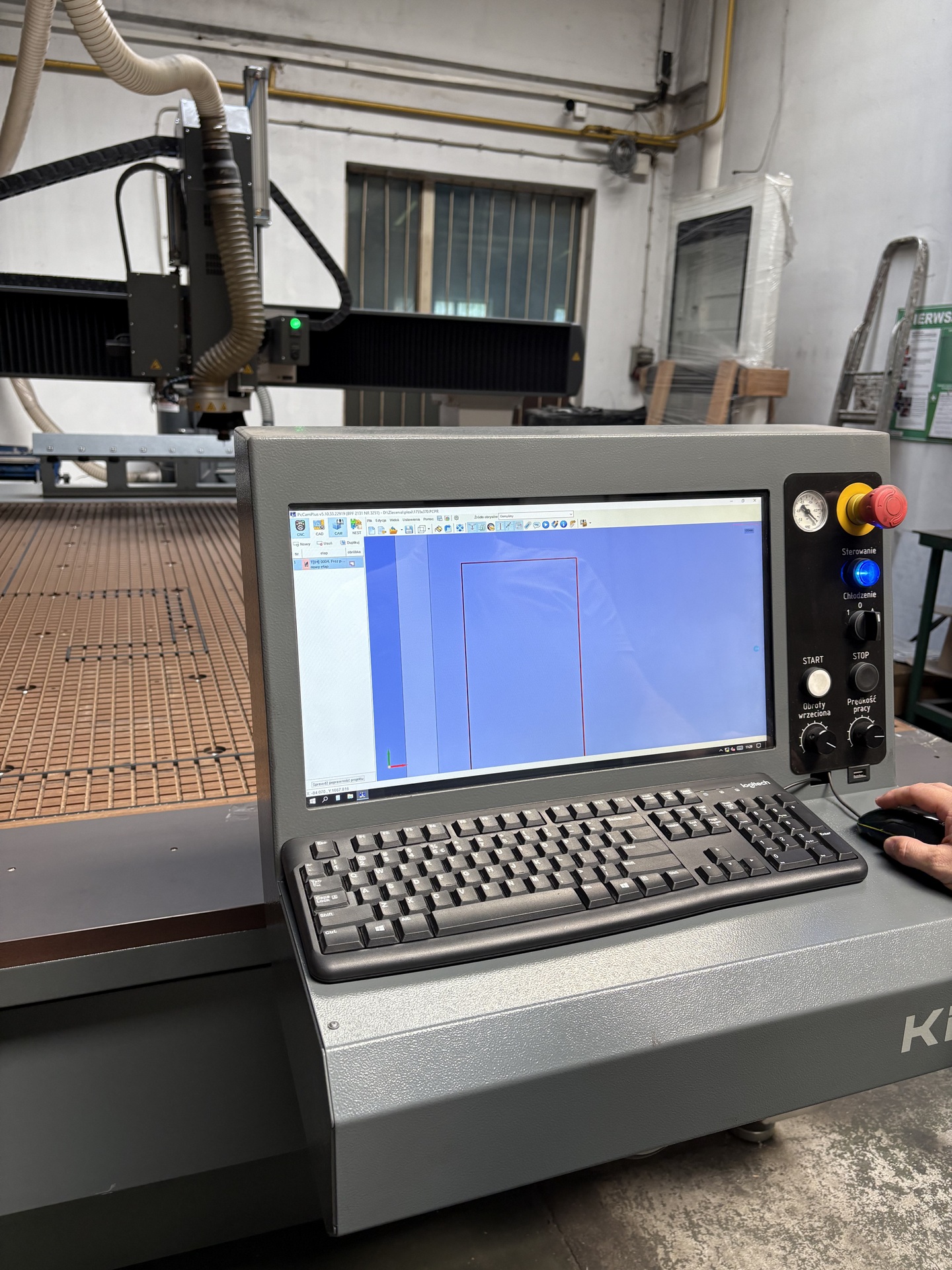

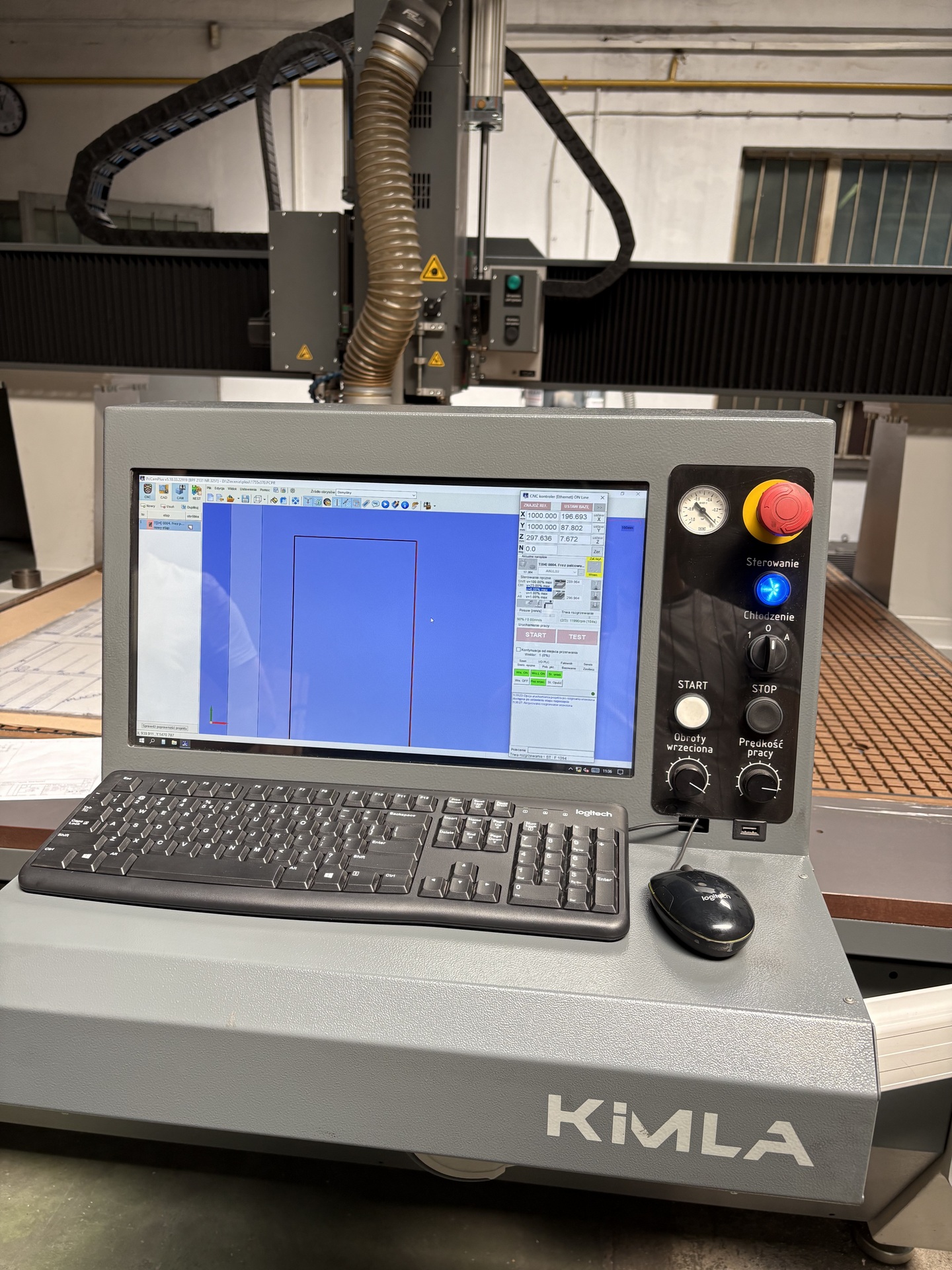

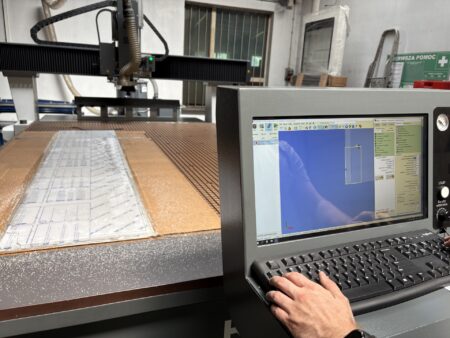

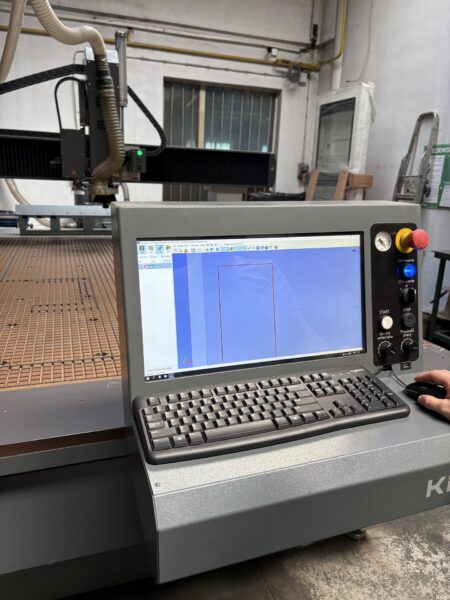

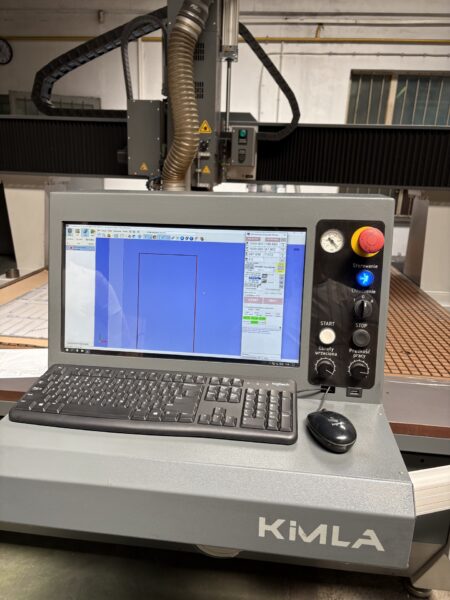

- CNC controller

- PC-CAM Plus software with 2.5D module

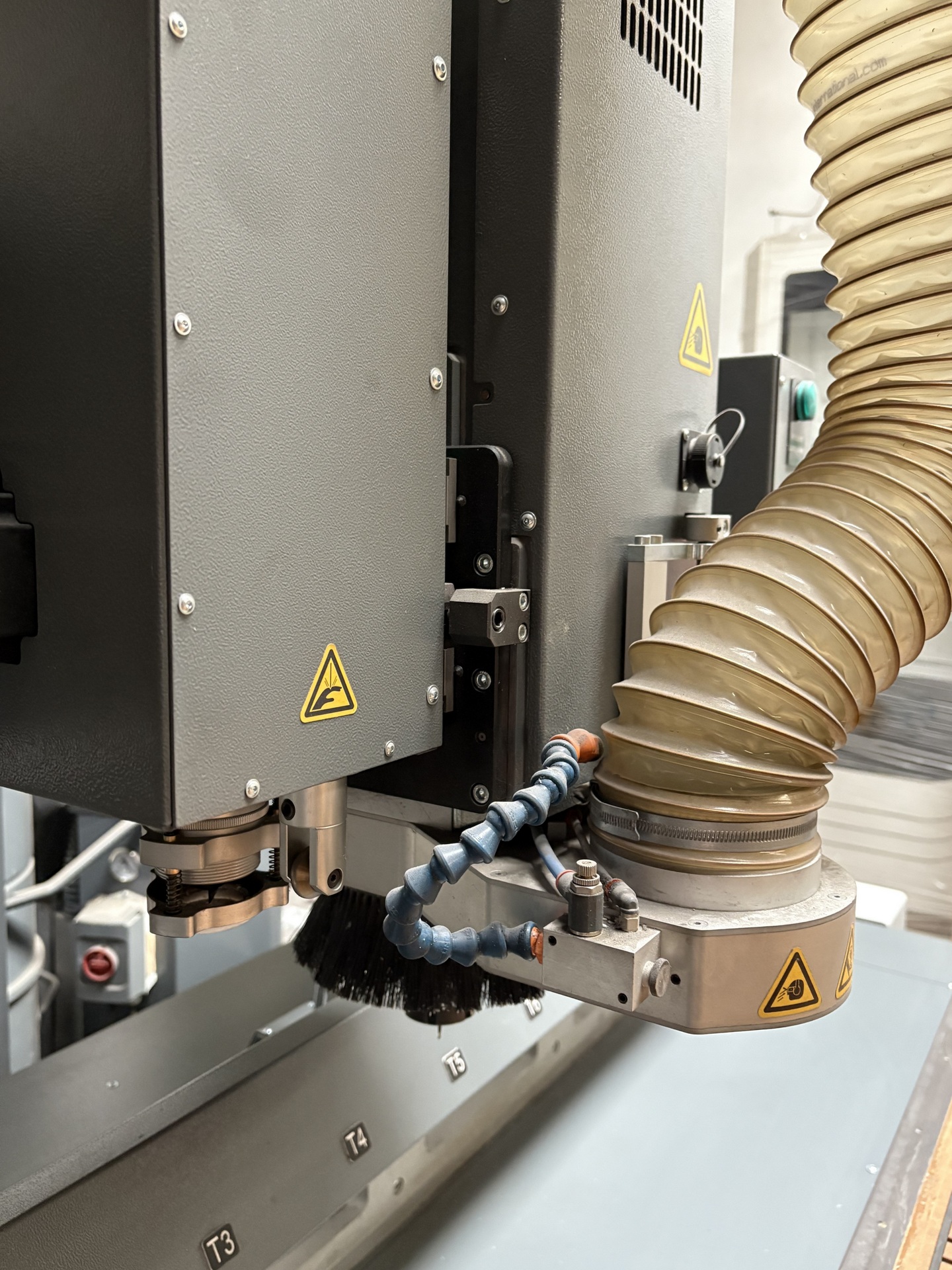

- creasing head

- servo cutting head

- vacuum pump: BECKER

- matrix vacuum table

- HSM (High Speed Machining) technology to speed up overall machining time

- tool correction sensor

- linear tool magazine

- automatic tool changing system

- AC digital servo drives in all axes

- automatic oil mist

- MEGAN 5.5 kW extraction system with extraction foot

- control panel

- tool holder ISO30 ER32 (10 pcs.)

- collet ER32 (10 pcs.)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe