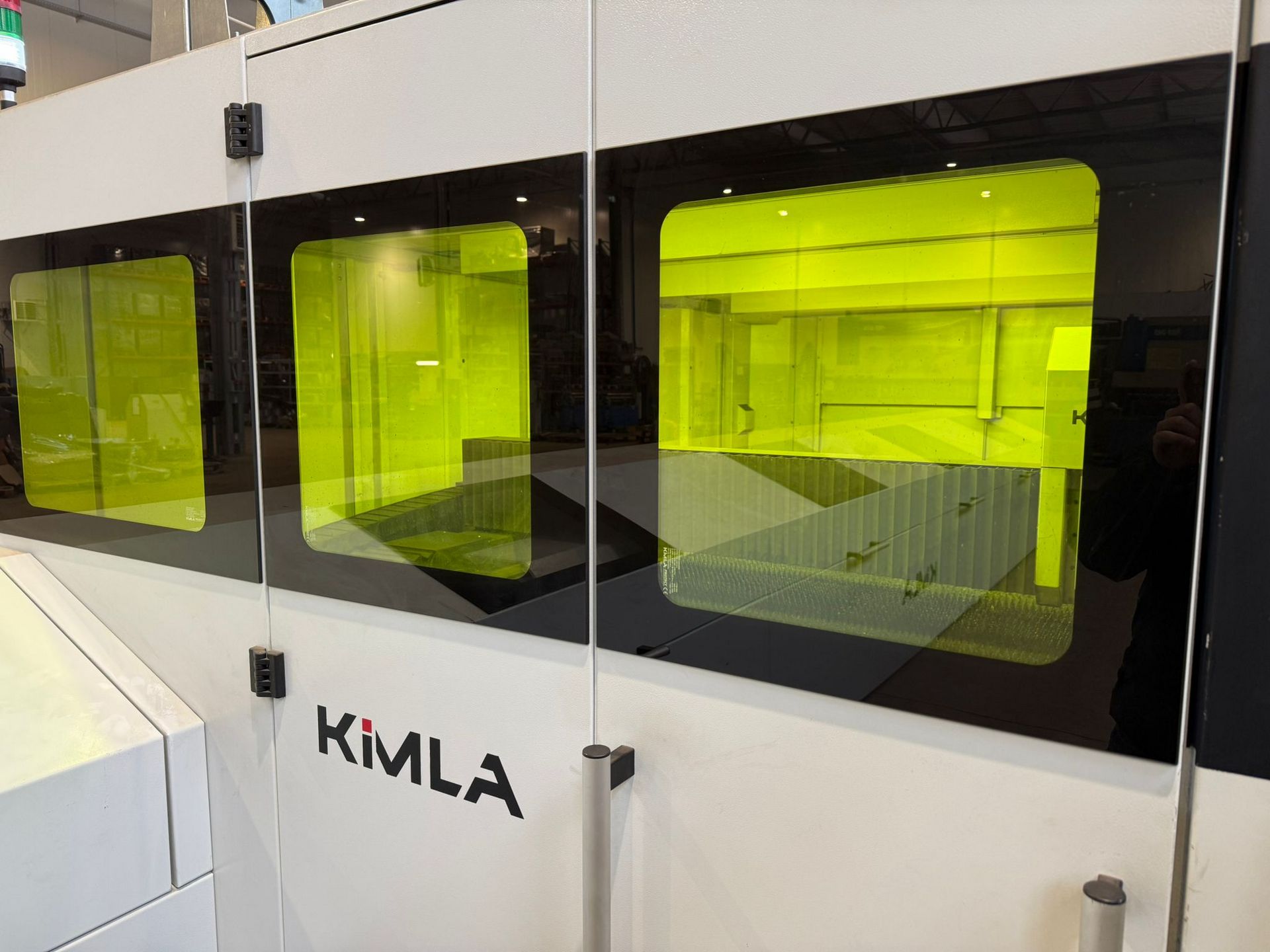

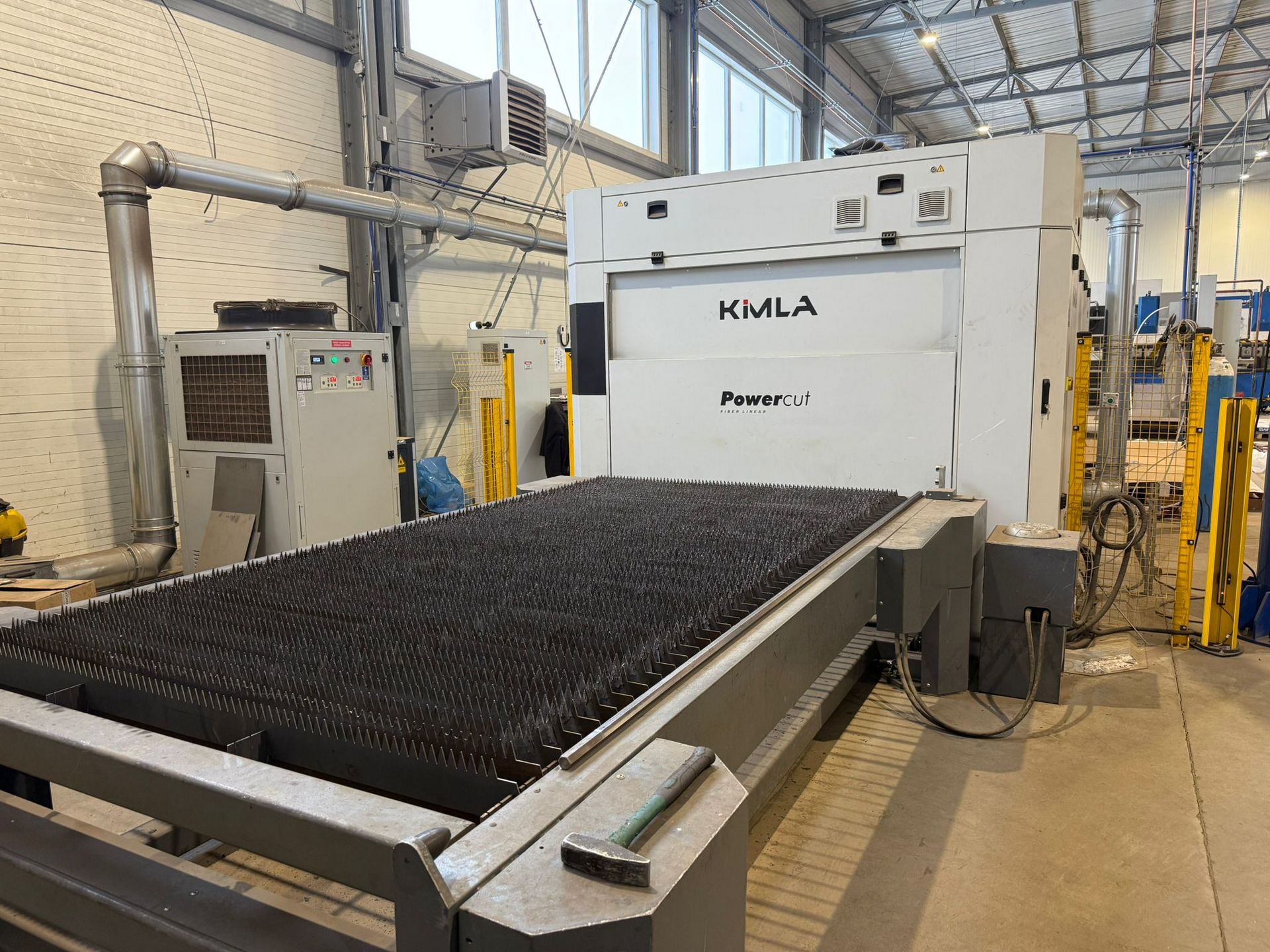

KIMLA POWERCUT LF 1530 6 kW laser cutting machine was built in 2022 in Poland by POLCOM Przemysław Kimla. The machine, distinguished by a number of state-of-the-art systems and technical solutions, is used for cutting sheet metal, tubes and profiles. The machining process is performed by a stable 6 kW fibre optic beam, which is generated by a resonator of the highest energy efficiency. The focusing lens system inside the cutting head in turn ensures optimum laser beam geometry for various types of workpieces.

All linear axes (X,Y,Z) are driven by powerful servo drives with innovative real-time Ethernet data transmission technology. This technology allows the configuration of four motion parameters (position, speed, acceleration and yaw). This solution guarantees unprecedented machine dynamics, especially when cutting complex shapes. The entire machining process is also supported by the automatic pallet exchange system, which allows simultaneous loading and unloading of workpieces during the cutting process.

The POWERCUT LF 1530 fibre laser is offered with an extensive range of equipment, including, among others, an interactive control system integrating CAD/CAM software and CNC control. Among the many advantages of such a solution, the machine operator is able to edit, correct, change geometry, lay out, generate a path and continue work at any time. The system also features automatic nesting with modules for production management, allowing the handling of orders and the production of parts from pre-prepared libraries.

The KIMLA POWERCUT tube and profile laser cutting machine was installed and launched in February 2023. Since then, the machine has worked only a total of 4450 hours.

Technical data of the KIMLA POWERCUT LF 1530 fiber laser

- laser power: 6 kW

- feed in the X/Y/Z axis: 1500/3000/120 mm

- feed rate in the X/Y/Z axis: 180/180/70 m/min

- maximum sheet metal size: 3050 x 1550 mm

- maximum sheet metal weight: 900 kg

- maximum rectangular profile cross-section: 100×100 mm

- minimum rectangular profile cross-section: 20×20 mm

- maximum tube diameter: 150 mm

- minimum tube diameter: 20 mm

- work table height: 850 mm

- table exchange speed: 1 m/s

- operating hours: 4450 h

- air pressure: 7 bar

- nitrogen pressure: 30 bar

- oxygen pressure: 10 bar

- power supply: 3x 400 V; 50 Hz

- machine dimensions without additional equipment (L x W x H): 4400 x 2800 x 2400 mm

- weight of the KIMLA POWERCUT LF 1530 machine: 10000 kg

Equipment of the KIMLA laser cutting machine

- CNC control

- CAD/CAM software

- integrated system for cutting tubes and rectangular profiles

- IPG laser source with safety module and power control system

- ability to cut with compressed air

- automatic pallet exchange system

- system for automatic sheet metal position detection and adjustment of the tool path to its position

- dedicated parametric laser beam modulator with the ability to shape the modulation characteristics

- automatic nozzle height adjustment calibration system

- 20 kHz linear motors in all axes

- measuring scales: RENISHAW

- DONALDSON Torit DCE multi-chamber extraction system with pulse cleaning

- two-sided gate drive

- multifunctional control panel

- integrated cooling system with digital temperature stabilisation

- work table with precise mechanical locking

- cutting gas supply system (oxygen and nitrogen) with pressure control and protection against pressure drops

- RJ45 port

- USB port

- waste containers

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe