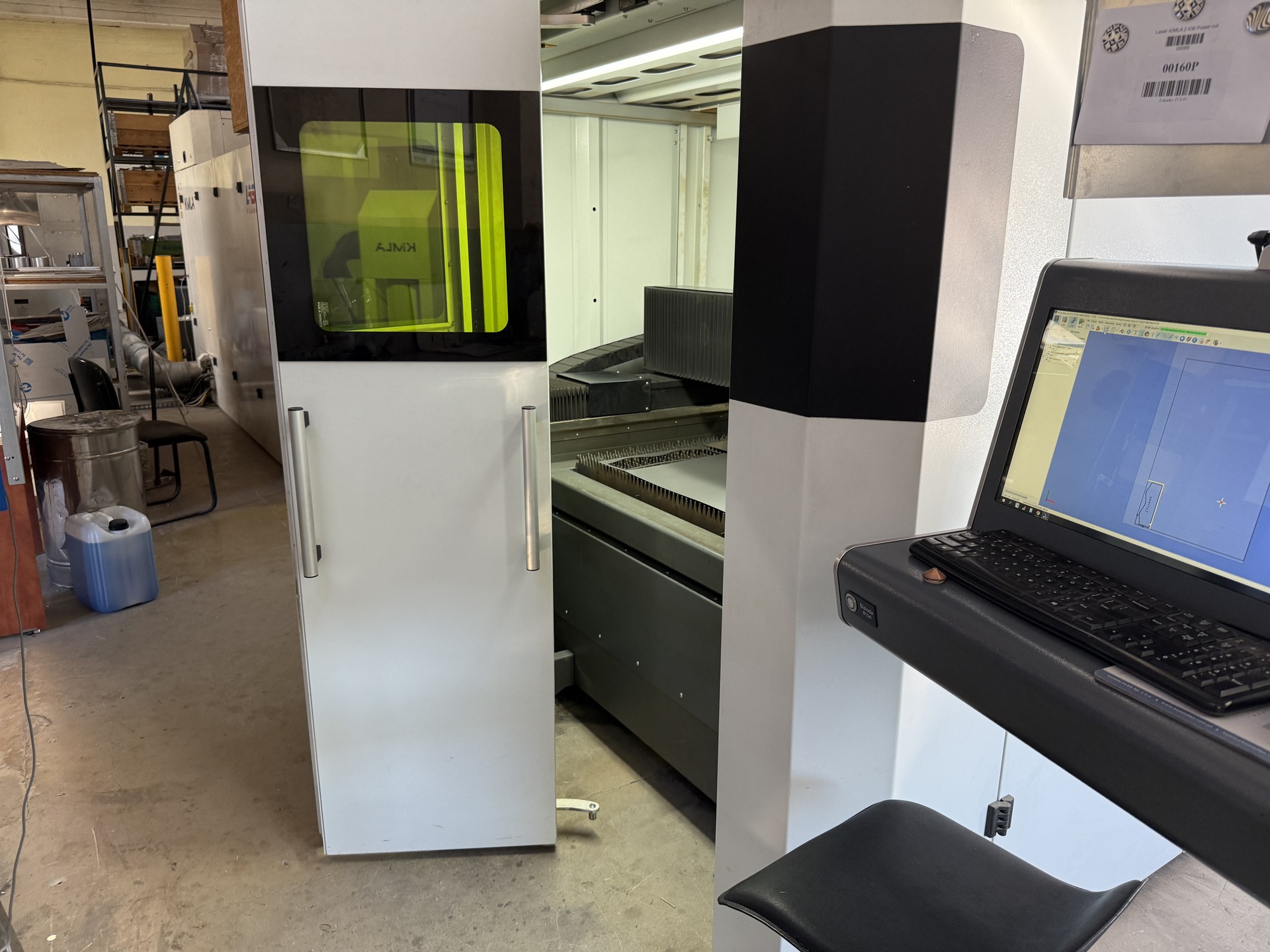

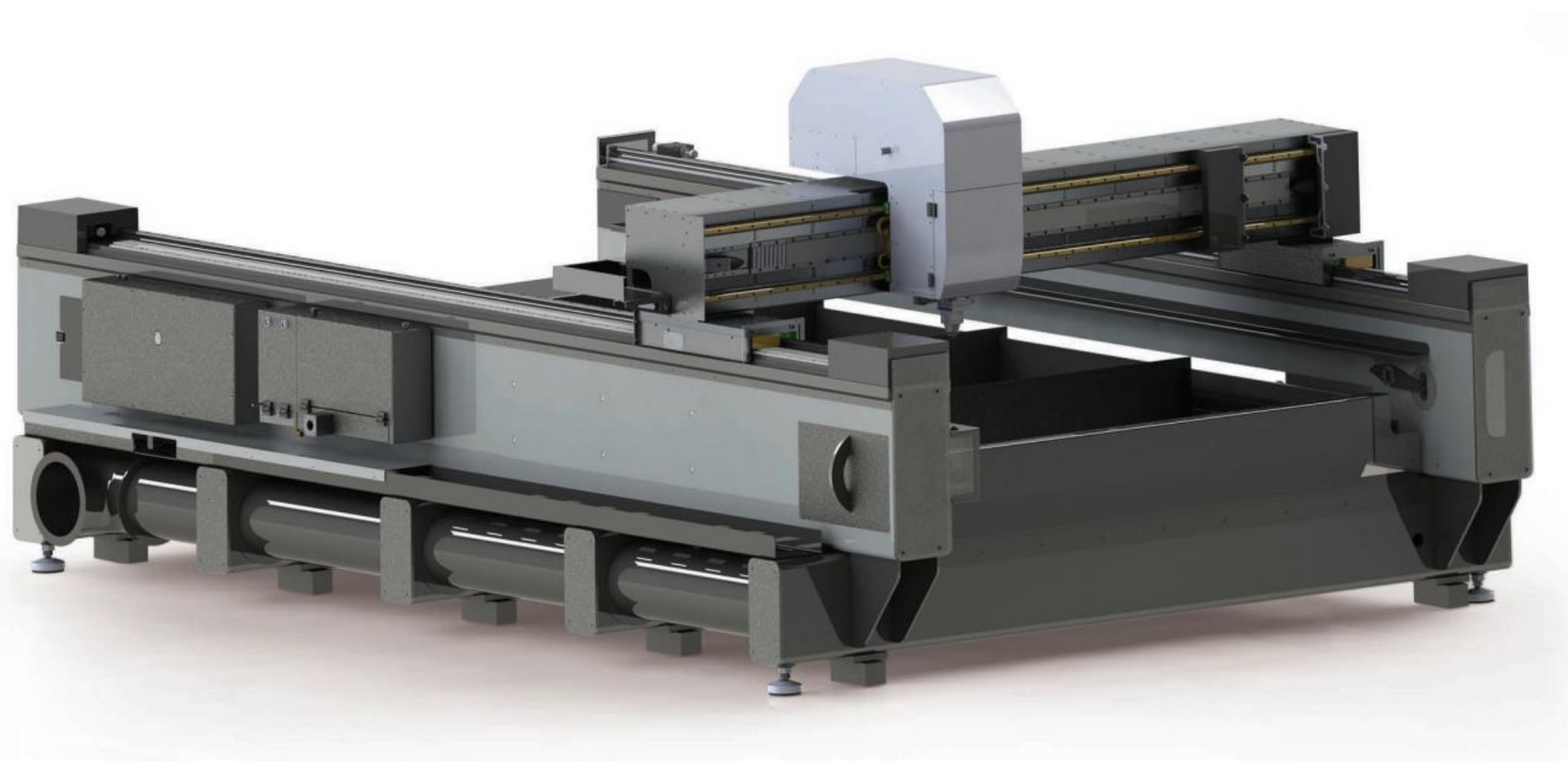

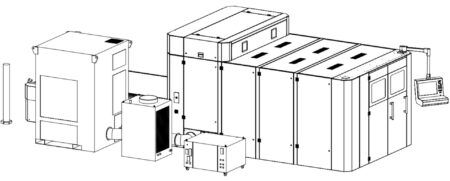

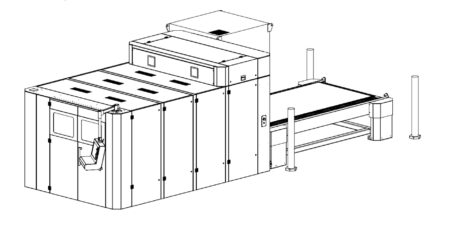

KIMLA POWERCUT LF1020 fiber laser was built in 2022 in Poland by POLCOM Przemysław Kimla. The machine has worked for a total of 814 hours and is in very good condition.

Laser cutting is performed by means of a stable 2 kW fibre beam, which is generated by a resonator of the highest energy efficiency. A focusing lens system inside the cutting head ensures optimum beam geometry for various types of workpieces. As a result, the edges of the machined workpieces are distinguished by their unprecedented smoothness and absence of irregularities.

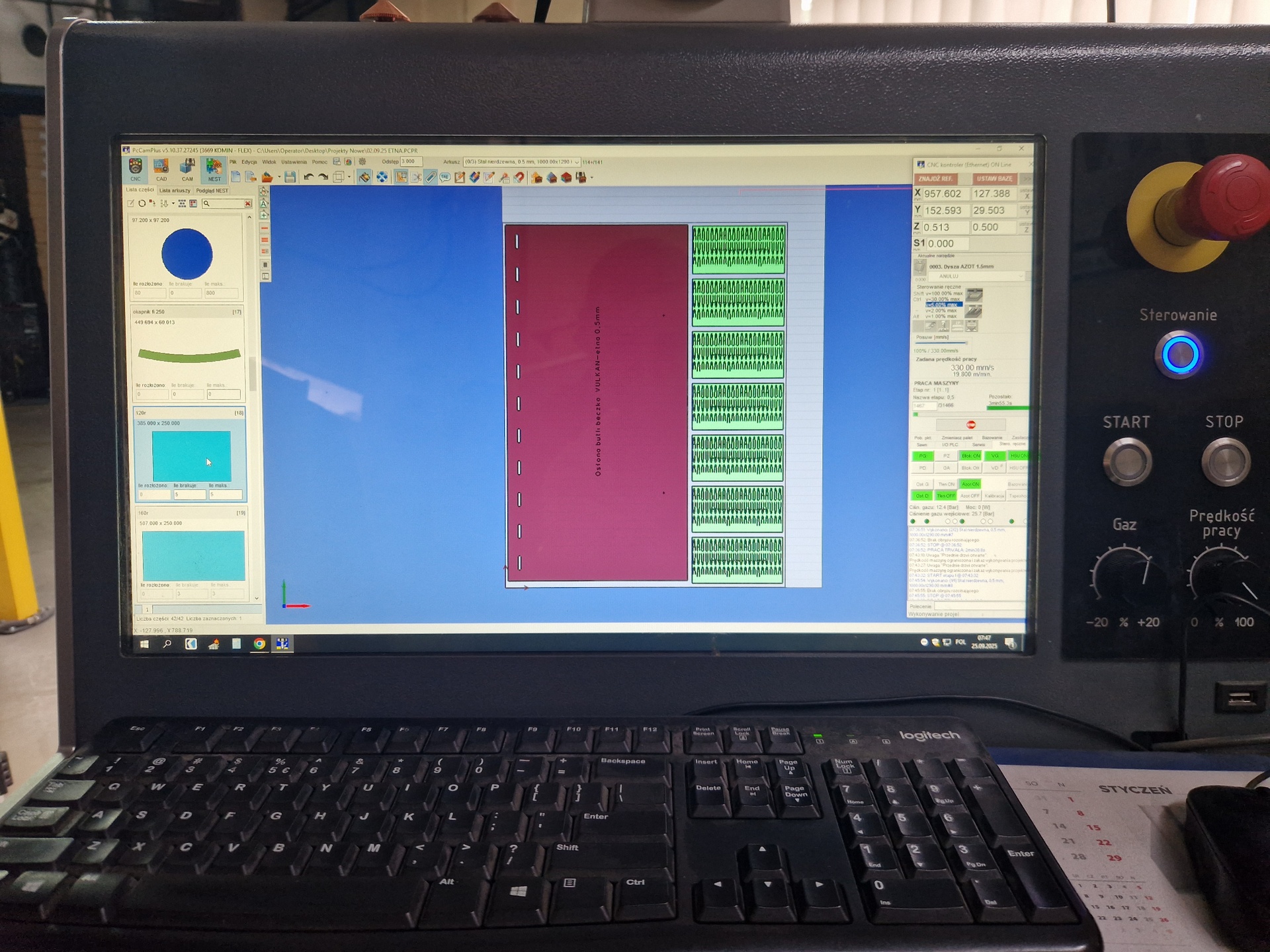

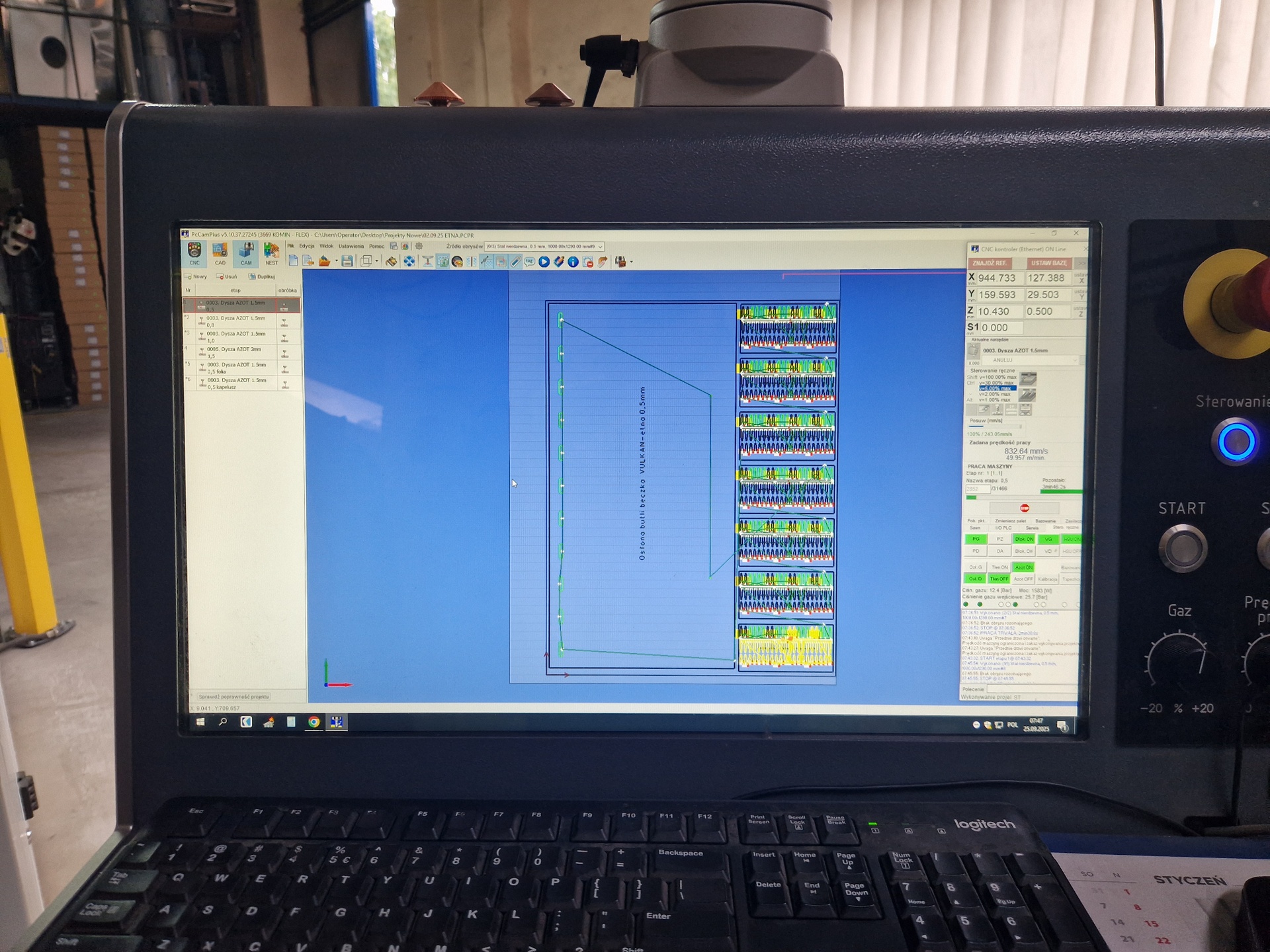

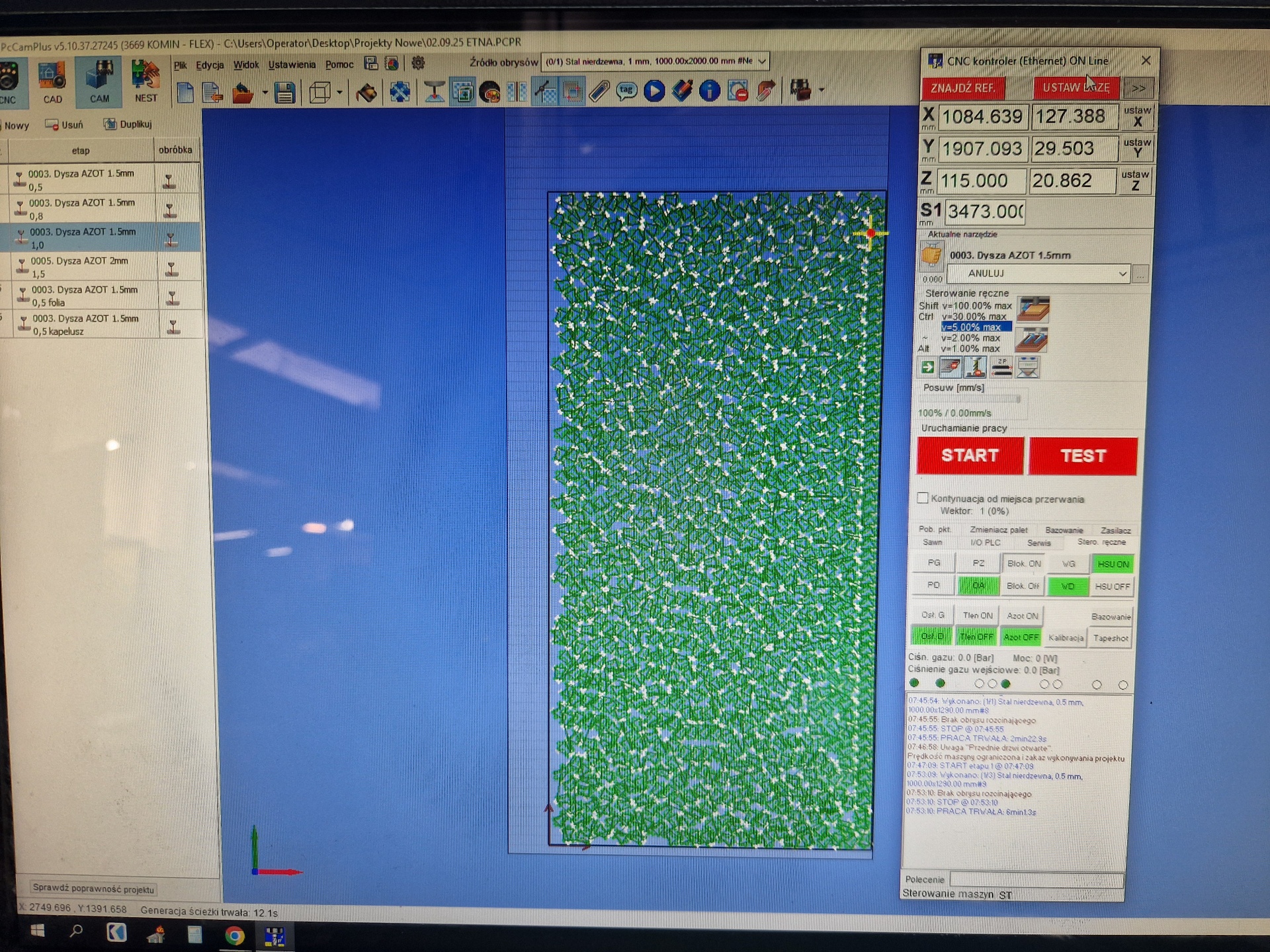

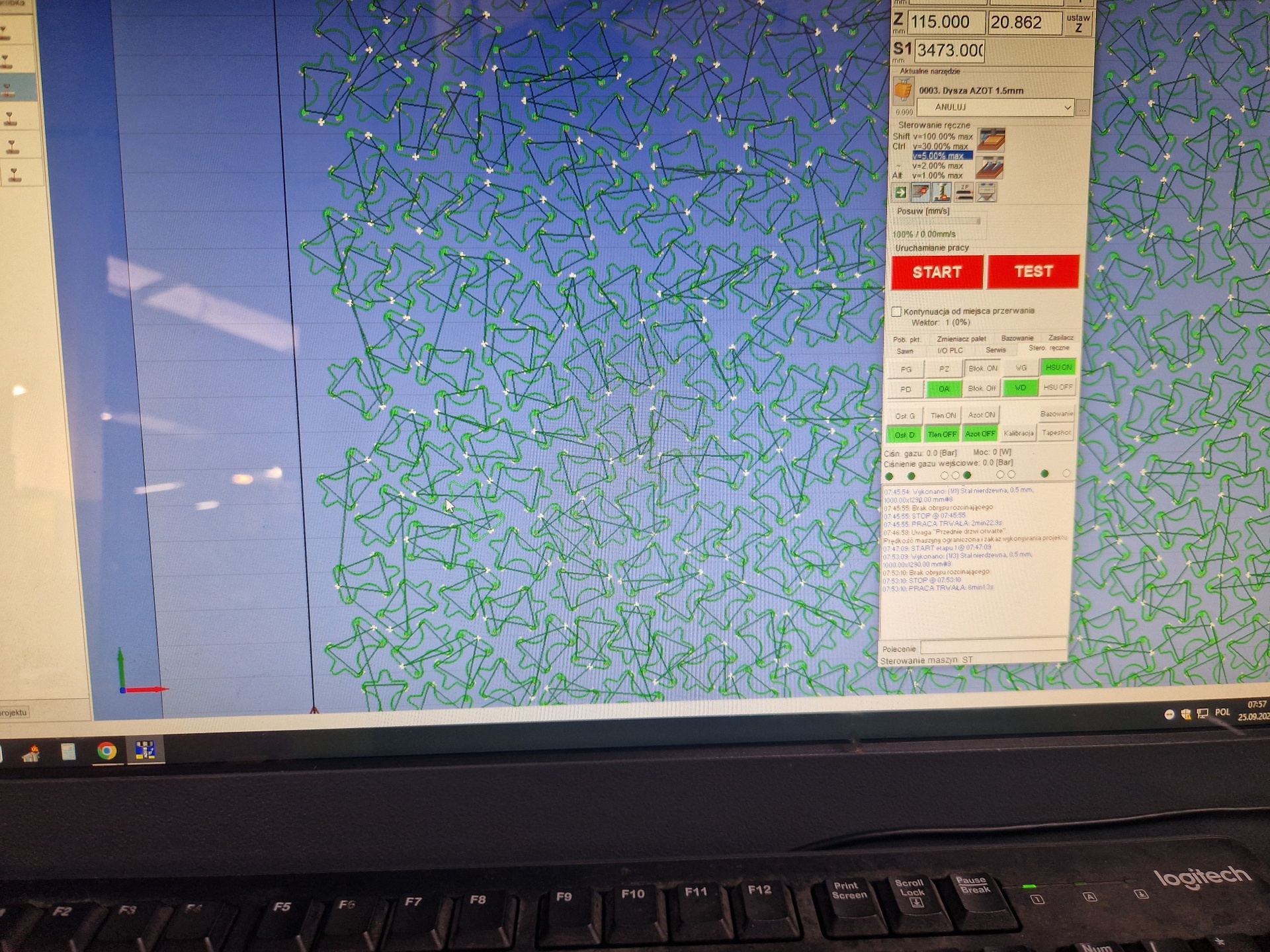

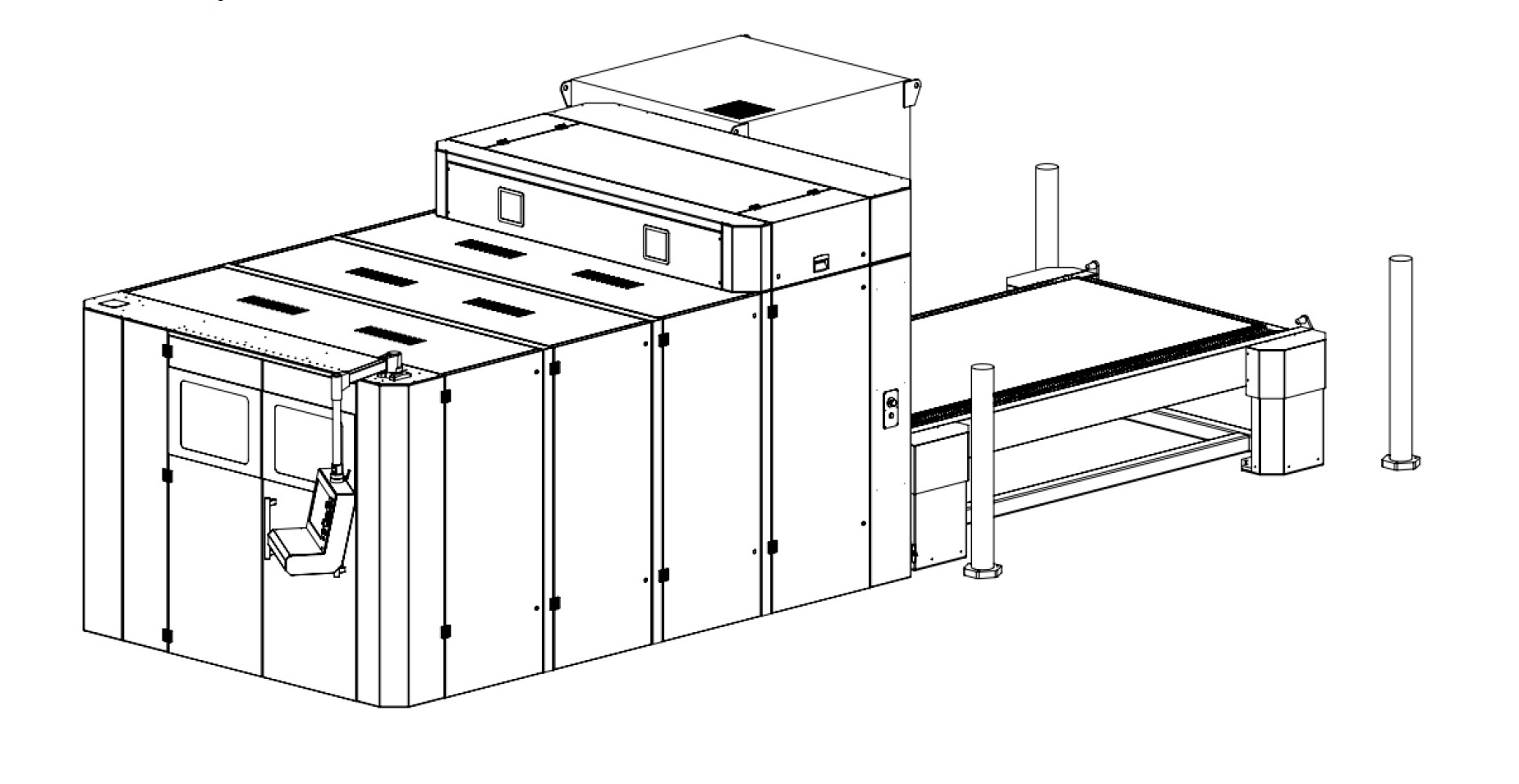

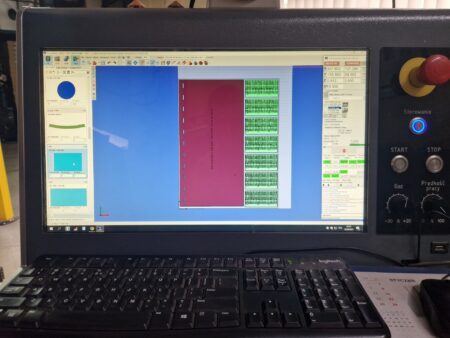

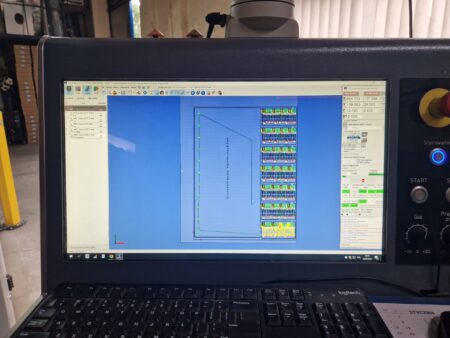

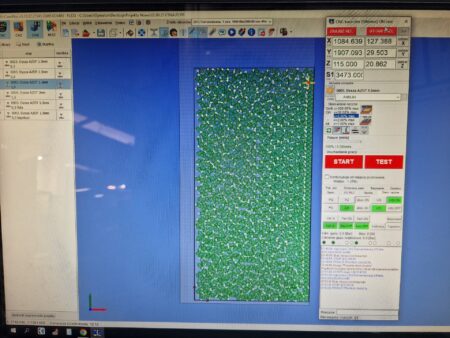

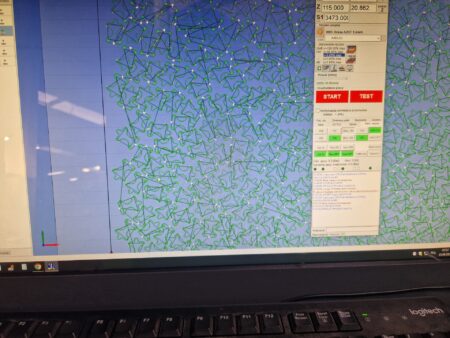

The entire machining process is fully automatic, thanks to the use of an automatic pallet exchange system. This system enables simultaneous loading and unloading of workpieces during cutting, thus increasing production efficiency and reducing machine downtime to a minimum. The POWERCUT LF1020 fibre laser is offered with an extensive range of equipment, which includes, among others, an interactive control system integrating CAD/CAM software and CNC control. Among the many advantages of such a solution, the machine operator is able to edit, correct, change geometry, lay out, generate a path and continue work at any time.

Technical specifications of the KIMLA POWERCUT LF1020 laser cutting machine

- laser power: 2 kW

- feed in the X/Y/Z axis: 1000/2000/120 mm

- feed rate in the X/Y/Z axis: 180/180/70 m/min

- maximum sheet metal dimensions (L x W): 2050 x 1050 mm

- maximum sheet metal weight: 600 kg

- maximum clearance under the head: 100 mm

- work table height: 850 mm

- table exchange speed: 1 m/s

- X and Y axis drive: 20 kHz linear motor

- Z axis drive: AC servo drive with digital encoder

- work table drive: chain

- operating hours: 814 h

- air pressure: 7 bar

- nitrogen pressure: 30 bar

- oxygen pressure: 10 bar

- power: 14 kW

- power supply: 400 V; 50 Hz

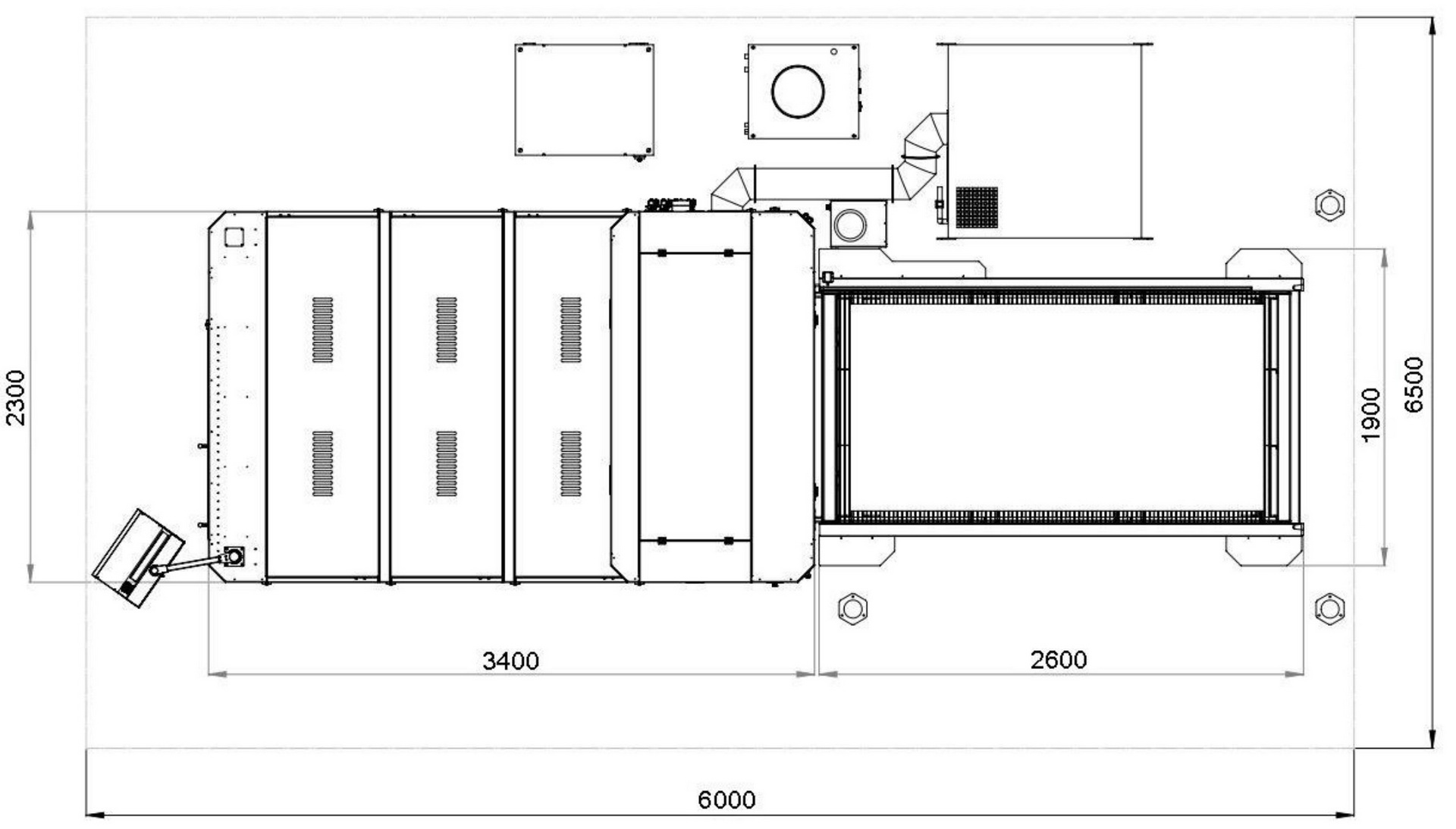

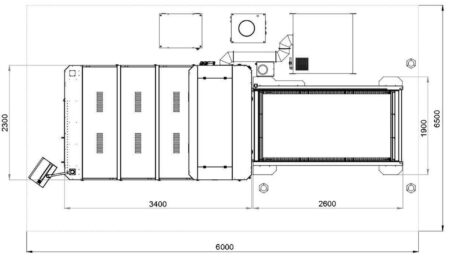

- minimum space requirement (L x W): 9000 x 6500 mmm

- machine dimensions without additional equipment (L x W x H): 2300 x 3400 x 2400 mm

- weight of the KIMLA POWERCUT LF1020 machine: 4700 kg

Equipment of the KIMLA laser cutting machine

- CNC controller

- CAD/CAM software

- IPG fibre optic resonator with safety module and power control system

- automatic pallet exchange system

- light curtains

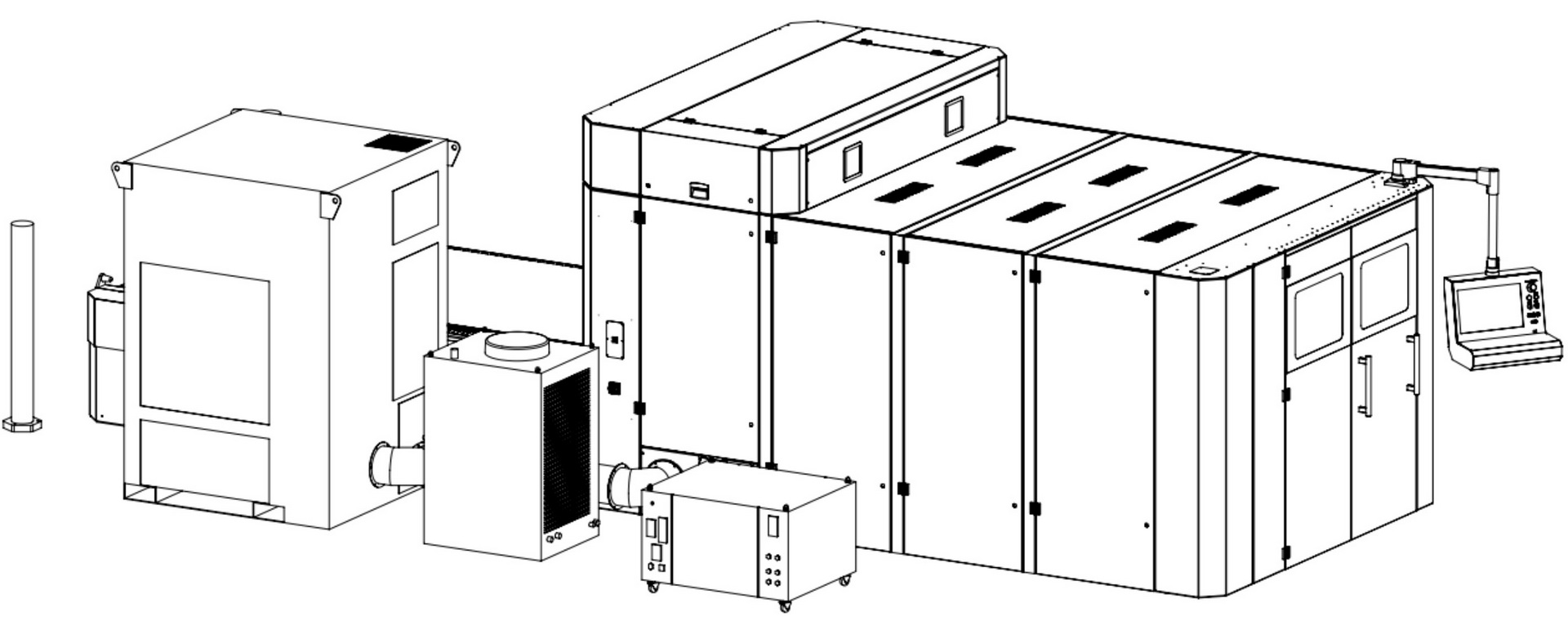

- DONALDSON DORIT TCE multi-chamber extraction system with pulse cleaning

- ability to cut with compressed air

- system for automatic sheet metal position detection and adjustment of the tool path to its position

- parametric laser beam modulator with shaping of modulation characteristics

- automatic head height adjustment calibration system

- RENISHAW measurement scales

- integrated cooling system with digital temperature stabilisation

- cutting gas supply system (oxygen and nitrogen) with pressure control and protection against pressure drops

- multifunctional control panel

- work table with precise mechanical locking

- laser radiation protection filters

- safety switch

- RJ45 port

- USB port

- waste containers

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe