KNUTH PICO TURN CNC lathe built in 2015 in Germany is the ideal choice for small-scale industries focused on unit and small batch production. Due to its extensive machining capabilities, sturdy design and high productivity, this compact size machine performs excellently in, among others, precision arc turning, threading and longitudinal and transverse workpiece turning. All operations are performed by a powerful spindle with variable speed adjustment between 150 and 1750 rpm. The KNUTH PICO TURN CNC lathe is additionally equipped with, among others, an automatic 4-position tool changer, an intuitive SIEMENS SINUMERIK 808D CNC controller and a 3-jaw chuck with a diameter of 125 mm. The total weight of the machine is 400 kg.

Technical specifications of the KNUTH PICO TURN mini metal lathe machine

- feed rates in the X/Z axis: 500/250 mm

- rapid traverse in the X/Z axis: 2000/1000 mm/min

- maximum turning diameter over bed: 250 mm

- maximum cross slide travel: 75 mm

- bed width: 135 mm

- tusk spacing: 550 mm

- maximum spindle rotational speed: 1750 rpm

- minimum spindle rotational speed: 150 rpm

- spindle taper: Morse MK3

- tailstock sleeve diameter: 30 mm

- tailstock sleeve stroke: 50 mm

- tailstock transverse adjustment: ± 4 mm

- tailstock sleeve taper: Morse MK2

- power: 1.6 kW

- power supply: 230 V; 50/60 Hz

- dimensions (L x W x H): 1200 x 530 x 1300 mm

- weight of machine: 400 kg

Equipment of the mini lathe

- CNC control: SIEMENS SINUMERIK 808D

- 3-jaw chuck ⌀ 125 mm

- automatic 4-position tool changer

- stepless spindle speed adjustment

- electronic wheel

- manual central lubrication

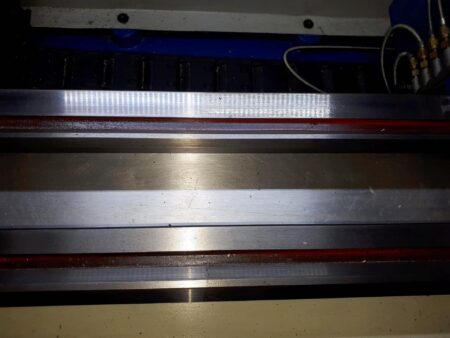

- ball screws

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe