KOLZER DGK36″ PVD sputtering machine was built in 2017. This specially constructed machine is used in the vacuum coating process, after which the workpieces are characterised by a “metallic effect” with high resistance to abrasion and chemical agents, as well as innovative colours. The PVD sputtering process involves the expulsion of metal atoms from a target (evaporation material) placed in the working chamber, which are then transferred and deposited onto the surface of the workpieces. In this operation, the target is exposed to a technological vacuum, consisting of process gas and high voltage. At the end, the workpiece surfaces are cleaned and activated by the plasma installed in the machine. This solution offers virtually unlimited possibilities for coating any type of surface.

In order to meet all demands and requirements, the KOLZER magnetron sputtering machine meets the highest industry standards and has a double loading system, which simplifies loading/unloading operations for subsequent production phases. The offer additionally includes a comprehensive range of equipment, consisting of, among others, a LAUDA chiller and numerous spare parts. During its entire service life, the KOLZER DGK 36 sputtering system has operated for just 2873 hours, in which it has performed 2580 work cycles. The total weight of the machine is 3000 kg.

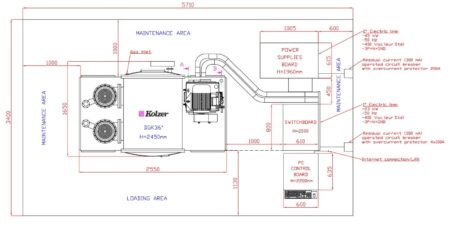

Technical data of the KOLZER DGK36″ PVD sputtering machine

- work chamber dimensions (dia. x d.) : ⌀ 1000 mm x 1300 mm

- industrial automation system in the form of a computer with an installed PLC based on Windows 10

- PVD sputtering source: 1 pc.

- PVD sputtering generator: 1 pc.

- plasma system: 1 pc.

- high vacuum diffusion pump: 2 pcs.

- automatic vacuum controller

- temperature and humidity conditioning of the generator panel

- horizontal carriage for easy loading/unloading of workpieces: 2 pcs.

- gas flow controller (Mass Flow Controller): 2 pcs.

- rotary system of satellite grips 6/4 positions: 2 pcs.

- chiller: LAUDA Ultracool 0240 SP

- spare parts

- stainless steel chamber cover: 2 pcs.

- operating hours: 2873 h

- CE certificate

- air pressure: 6 bar

- space requirement (L x W): 5710 x 3400 mm

- power supply: 3x 400 V; 50 Hz

- weight of machine: 3000 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe