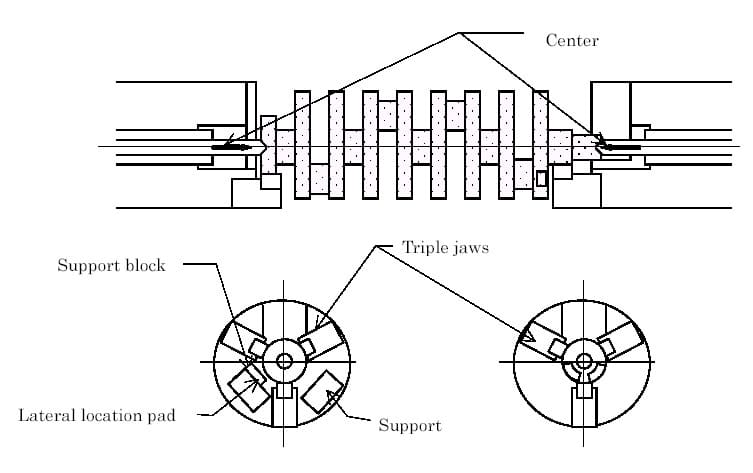

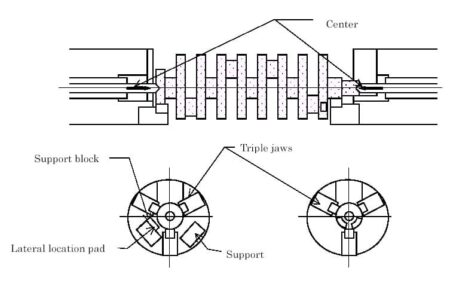

The KOMATSU GPM 200F2-3 CNC crankshaft machining center was built in 2002 in Japan by Komatsu Machinery Corp. The machine is used to process crankshafts with a maximum length of 700 mm. The working head of the machine was manufactured and rigidly bolted to the bed. A chuck with centering triple jaws in a cast steel housing is mounted on the head, operating with a clamping force of 80 kN. The mounted steady allows for stable machining, preventing vibrations during the cutting of the detail. The cross slide moves longitudinally on the bed guides by means of an AC (alternating current) actuator. The machine tool works in six axes (X1, X2, Y1, Y2, Z1, Z2) computer-controlled by the CNC controller SIEMENS Sinumerik 840D. The maximum feeds are +/- 172.5 mm (for the X1 and X2 axes), +/- 95 mm (for the Y1 and Y2 axes) and +/- 450 mm (for the Z1 and Z2 axes). On the other hand, rapid feeds in the X, Y, Z axes are respectively 12,040 mm/min, 6,700 mm/min and 14,400 mm/min. The machine is equipped with two 37 kW spindles, each rotating at a speed of 188 rpm. The GPM 200F2-3 machining center weighs 26 tons.

Characteristics of KOMATSU GPM 200F2-3 machine for crankshafts

– CNC control: SIEMENS Sinumerik 840DM

– number of controlled axes: 6

– maximum detail length: 700 mm

– minimum eccentric diameter: 210 mm

– minimum diameter of the main journal: ƒ50 mm

– height of the chuck center: 1280 mm

– maximum feed in axes:

X1: +/- 172.5 mm (tool center 95 mm)

X2: +/- 172.5 mm (tool center 95 mm)

Y1: +/- 95 mm

Y2: +/- 95 mm

Z1: +/- 450 mm

Z2: +/- 450 mm

– maximum rapid feed in the axes:

X: 12040 mm/min

Y: 6700 mm/min

Z: 14400 mm/min

– X, Y, Z axis actuator: SIEMENS 1FT6 with an brake Absolute

– number of spindles: 2

– spindle motor power: 37 kw

– spindle speed: 188 rpm

– cutting speed 142 m/min

– tool diameter: 240 mm

– workpiece steady

– workpiece head (2 pcs.)

– hydraulic unit tank capacity: 100 l

– voltage: alternating current, 3-phase, 380V +/- 10%, 50Hz +/- 1Hz

– machine height: 2950 mm

– total weight of the GPM 200F2-3 machine: 26 t

Process of machining a workpiece in KOMATSU GPM 200F2-3

1. The workpiece is loaded,

2. The chucks are clamped,

3. Z1 and Z2 axes are moving,

4. Tools are moving on the surface (axes X1, X2 and Y1, Y2),

5. Release of the support,

6. Axes Z1 Z2 move to rest position,

7. Release of the chuck,

8. Unloading of workpiece.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe