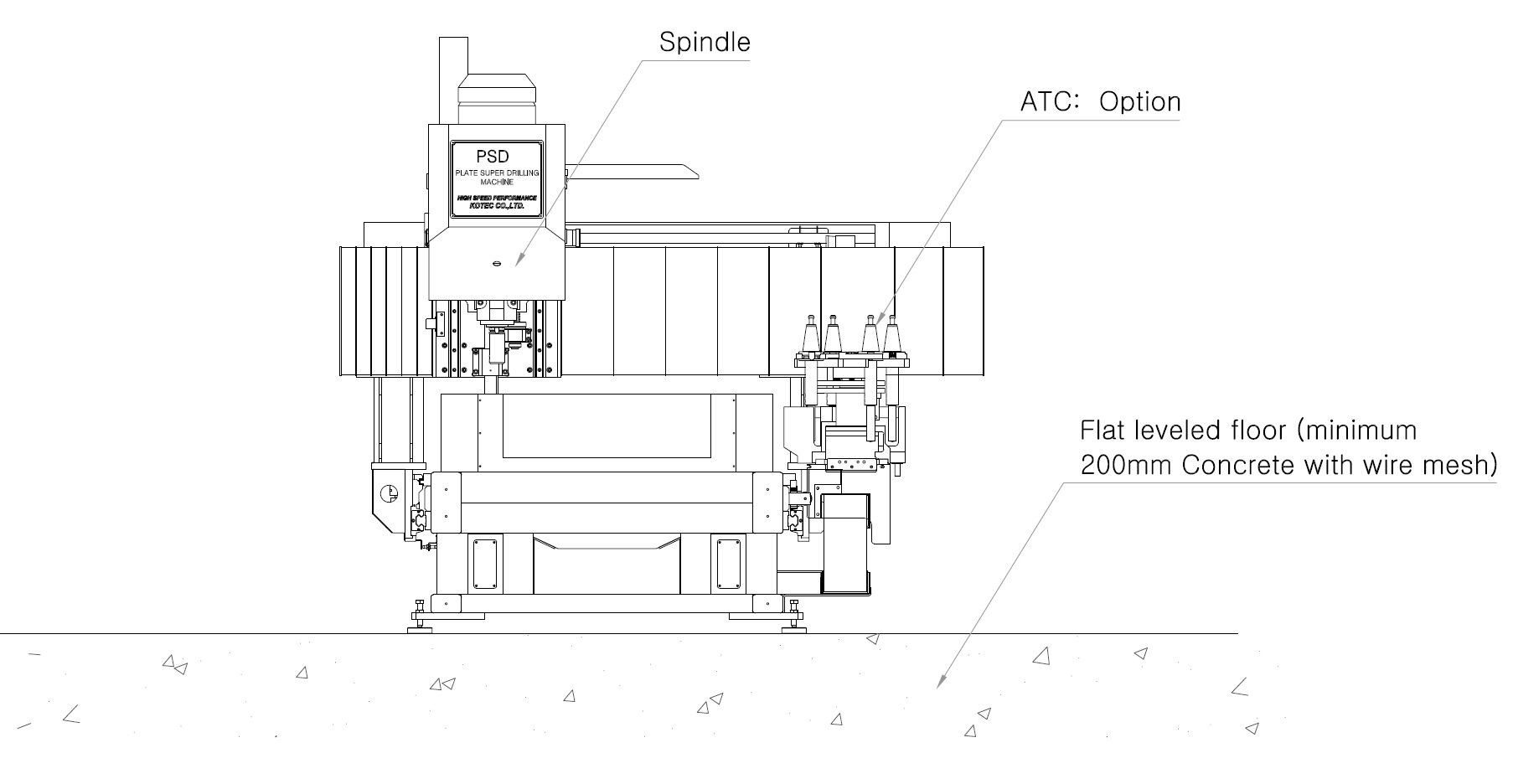

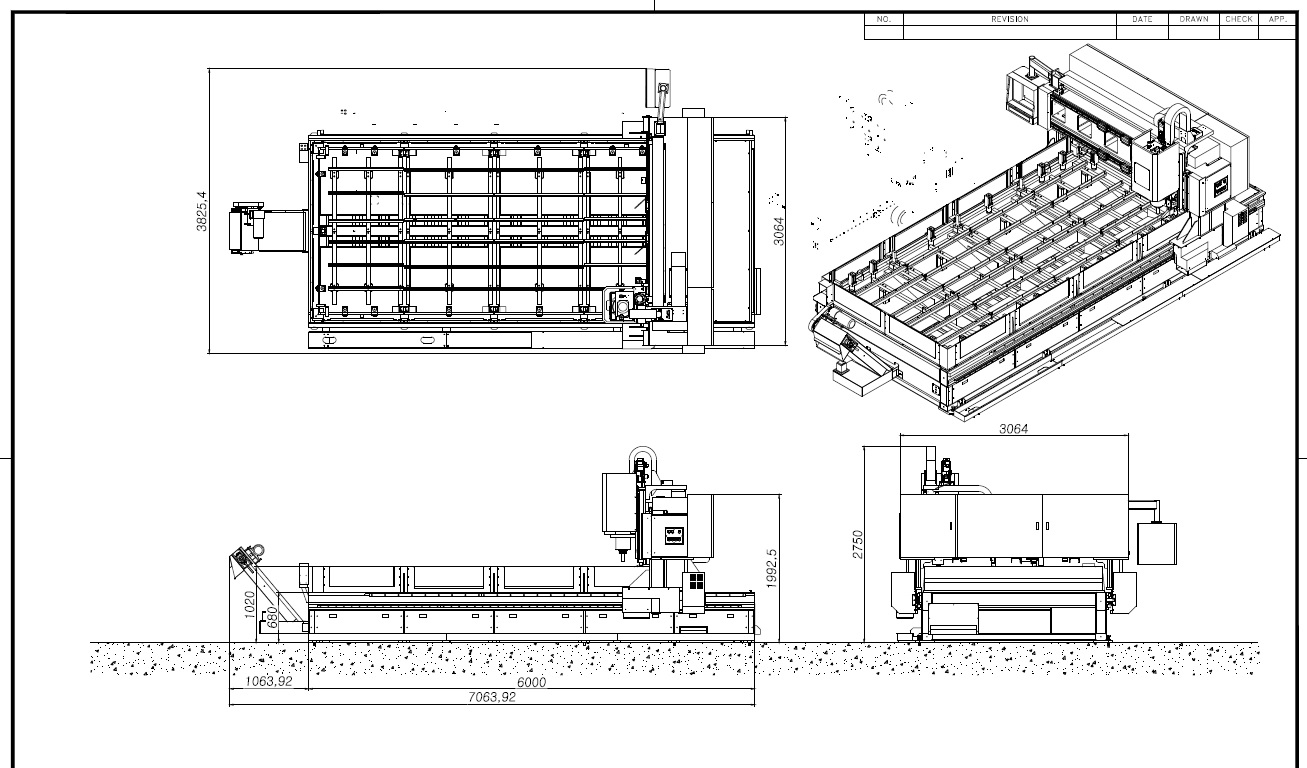

KOTEC PSD-4520 CNC drilling machine was built in 2020 in South Korea by KOTEC Co., Ltd. The machine, which is designed for drilling precision holes and threading, is an excellent choice for companies specialising in, among others, the construction of machinery or the production of steel structures. The machining process is performed in three axes (X,Y,Z) on a large work area with a length of 4500 mm and a width of 2000 mm. A number of state-of-the-art components, combined with an extremely stable design, guarantee the best results, even during the most intensive machining. All this is complemented by an advanced CNC control with an intuitive interface and all the necessary functions. The KOTEC PSD 4520 CNC beam drilling machine weighs approximately 8900 kg.

Technical specifications of the KOTEC PSD-4520 CNC metal drilling machine

- number of axes: 3 (X,Y,Z)

- feed in the X/Y axis: 4050/2050 mm

- maximum machining capacity (L x W): 4500 x 2000 mm

- maximum spindle rotational speed: 1800 rpm

- spindle drive power: 18.5 kW

- spindle taper: BT50

- maximum drill bit diameter (carbide): 50 mm

- maximum drill bit diameter (HSS): 50 mm

- hydraulic hold-down stroke: 20-105 mm

- power: 27.1 kW

- power supply: 3x 400 V; 50 Hz

- dimensions (L x W x H): approx. 7064 x 3825 x 2750 mm

- weight of the KOTEC PSD-4520 machine: approx. 8900 kg

Equipment of the KOTEC drilling machine

- CNC controller

- AC servo motors on all axes

- VP-40F hydraulic pump

- chip conveyor

- hydraulic hold-downs (16 pcs.)

- cooling unit

- USB port

- Ethernet interface

(The technical parameters given may differ slightly from reality. A verification with the actual capabilities of the offered machine is required.)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe