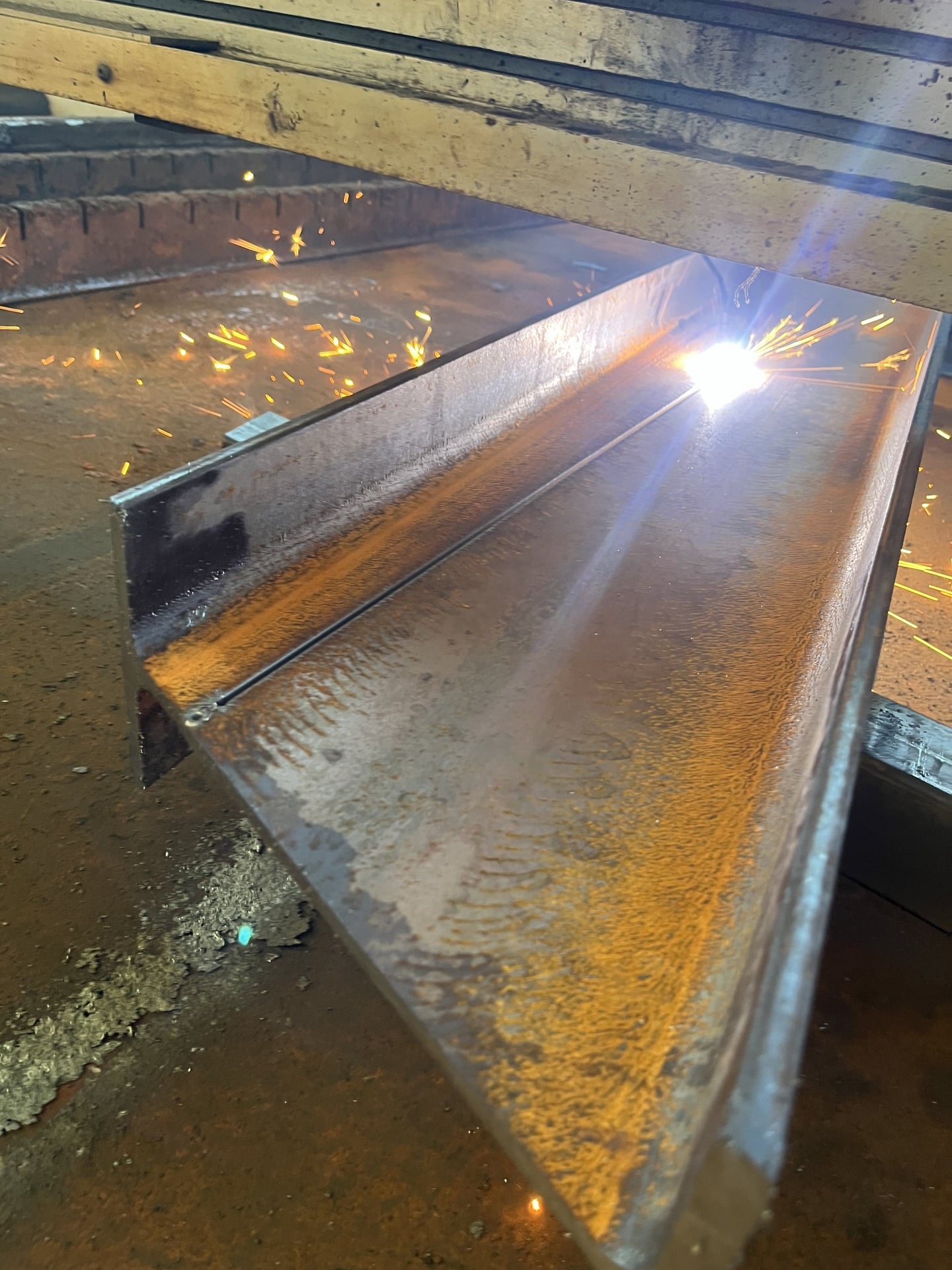

KT7 CNC KTP 300-150 plasma cutting machine was built in 2016 in Poland. The machine, designed for machining workpieces with a maximum thickness of 32 mm, has a stable waterbed table that ensures clean cutting, material cooling and reduces gas emissions during machining. Workpieces produced in this way stand out for their excellent precision and do not require other secondary processes to be undertaken. In addition, the machine’s compact design and all its components have been hot-dip galvanised and powder-coated to prevent rust and guarantee trouble-free operation throughout its lifetime. The equipment includes among others CAM software and a powerful plasma source HYPERTHERM. The KTP 300-150 plasma cutting machine weighs 800 kg.

Technical specifications of the KT7 CNC KTP 300-150 plasma cutting machine

- maximum sheet metal thickness: 32 mm

- maximum sheet metal weight: 2000 kg

- working speed: 0-160000 mm/min

- torque in X/Y/Z axis: 8.7/4.7/3.2 Nm

- ambient temperature: 5-40°C

- power supply: 230 VAC; 50 Hz

- dimensions (L x W x H): 3500 x 1900 x 1400 mm

- weight of machine: 800 kg

Equipment of the KT7 CNC plasma cutting machine

- CNC controller

- CAM software

- plasma source: HYPERTHERM POWERMAX 105

- sheet metal detection system

- THC torch height control system

- waterbed table

- ergonomic control panel with 19″ screen

- control cabinet

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe