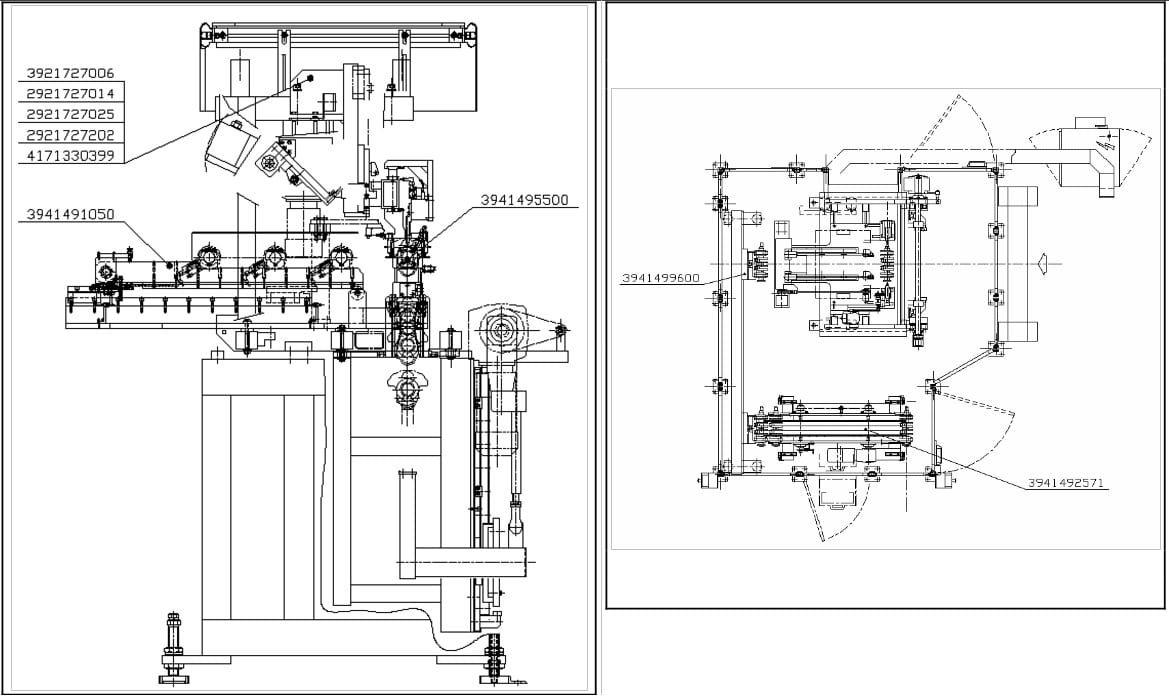

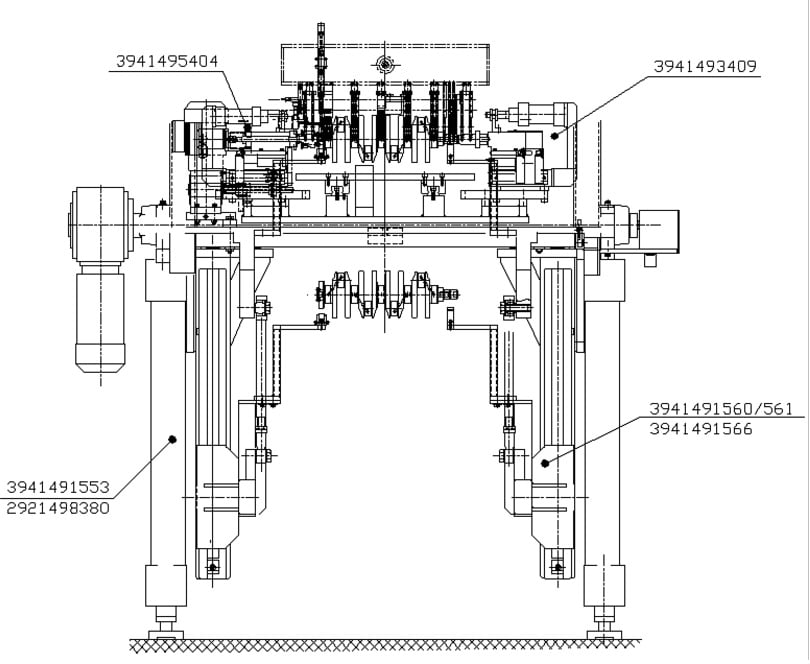

The MARPOSS M110 measuring machine for crankshafts was built in 2002 in Italy. The machine is measuring SDI 4-cylinder engine shaft using a dynamic method. The equipment consists of, among others: a RITTAL SK3203-100 air conditioner, a channel for reject parts with capacity of 10 pieces, a shuttle conveyor and a PLC controller SIEMENS S7-300.

The following checks are carried out on the motor shaft:

– measurement of the width of the central thrust bearing

– measurement of the distance between the thrust bearing and the end of the shank

– measurement of the wobble of the spindle end face

– measurement of perpendicularity of the stem end face

– measurement of wobble of the thrust bearing end face

– measurement of perpendicularity of the thrust bearing end face

Description of the measuring cycle

1. Blocking of a pallet with a workpiece under the measuring station by prestop

2. Lifting the engine crankshaft for measurement by a hoist

3. Correction of the angular orientation by two guides acting on the first crankpin on the flywheel side

4. Closing of the loose blade and the motorised blade

5. Entry into the corresponding holes on the workpiece of the mandrels placed on the motorised blade in order to properly draw the workpiece during rotation

6. Transfer the measuring cells to the workpiece via the geared motor

7. Take measurements after half-rotation of the workpiece

8. Return the workpiece after half-rotation with the same orientation as at the time of loading

9. Lifting of the measuring cells

10. Opening of the blades and counterblades

11. Transfer of the workpiece back to the pallet

Technical specifications of the MARPOSS M110 measuring machine for crankshafts

- PLC controller: SIEMENS S7-300

- electronic measuring device: Marposs E9066

- air conditioner: RITTAL SK3203-100

- channel for rejected workpieces with a capacity of 10 pcs.

- number of measuring bits: 14

- total number of measurements: 9

- workpiece cycle time: 22 seconds

- cleaning and calibration cycle time: 42 seconds

- discharge time of knocked-out workpieces: 29 seconds

- drive type: electromechanical and pneumatic

- working pressure: 0.45 MPa

- safety pressure: 0.40 MPa

- supply voltage: 24 Vdc

- average air consumption: 6 Nm3/h

- supply: 380Vac three-phase; 50Hz

- maximum power consumption: 5 KVA

- nominal current: 7.5 A

- MARPOSS M110 machine size (L x W x H): 4400 x 3850 x 2600 mm

- total weight of apparatus: 3500 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe