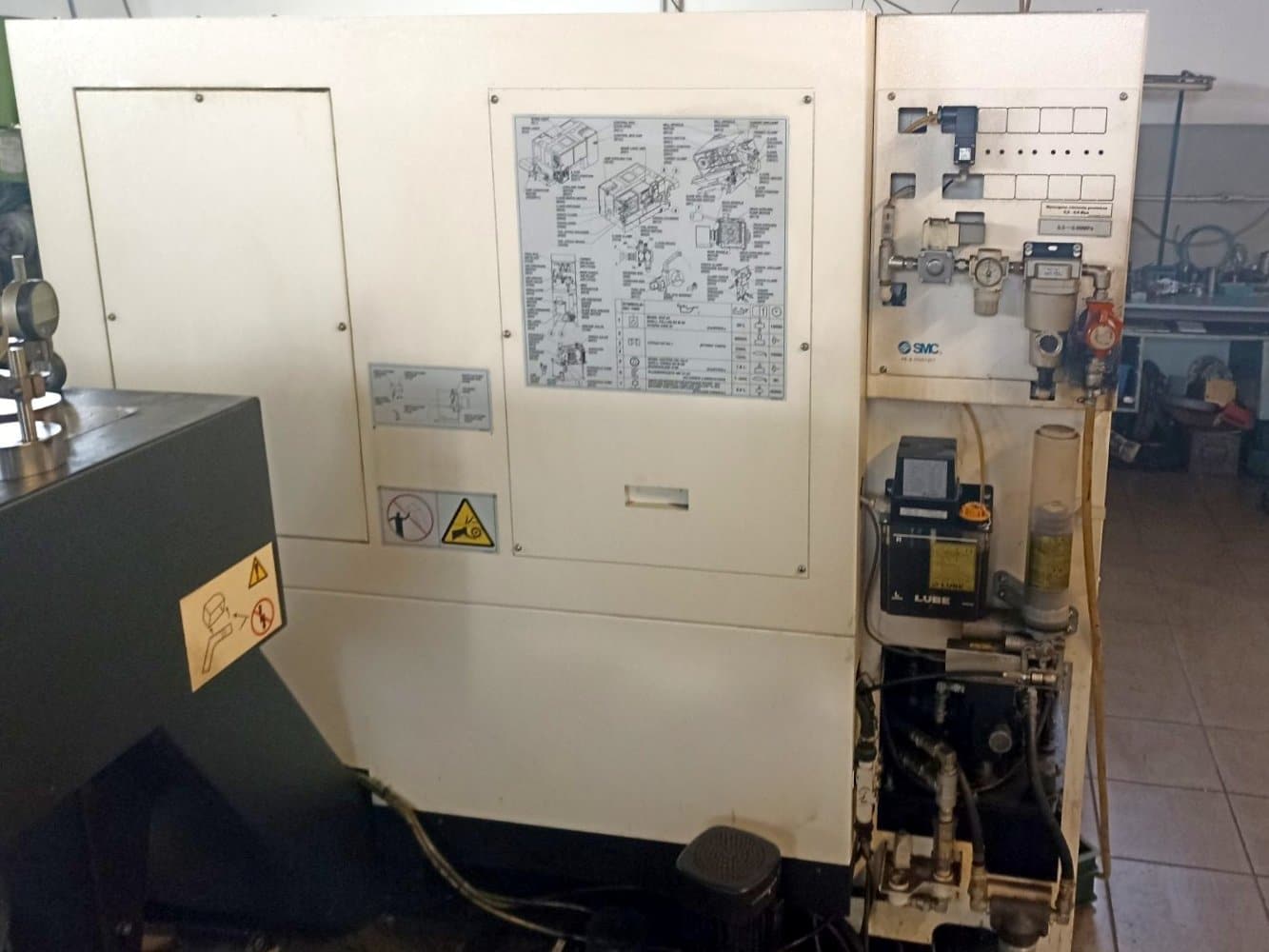

MAZAK QUICK TURN SMART 200L CNC lathe manufactured in 2015 is used for machining metal workpieces with a maximum diameter of 350 mm and a maximum weight of 20 kg. The lathe processes the workpiece in X and Z axes with feeds of 195 mm (X axis) and 560 mm (Z axis) respectively. The machine structure has been specially designed to significantly minimise vibration during high-speed machining, achieving outstanding workpiece quality and extending the service life of the tools.

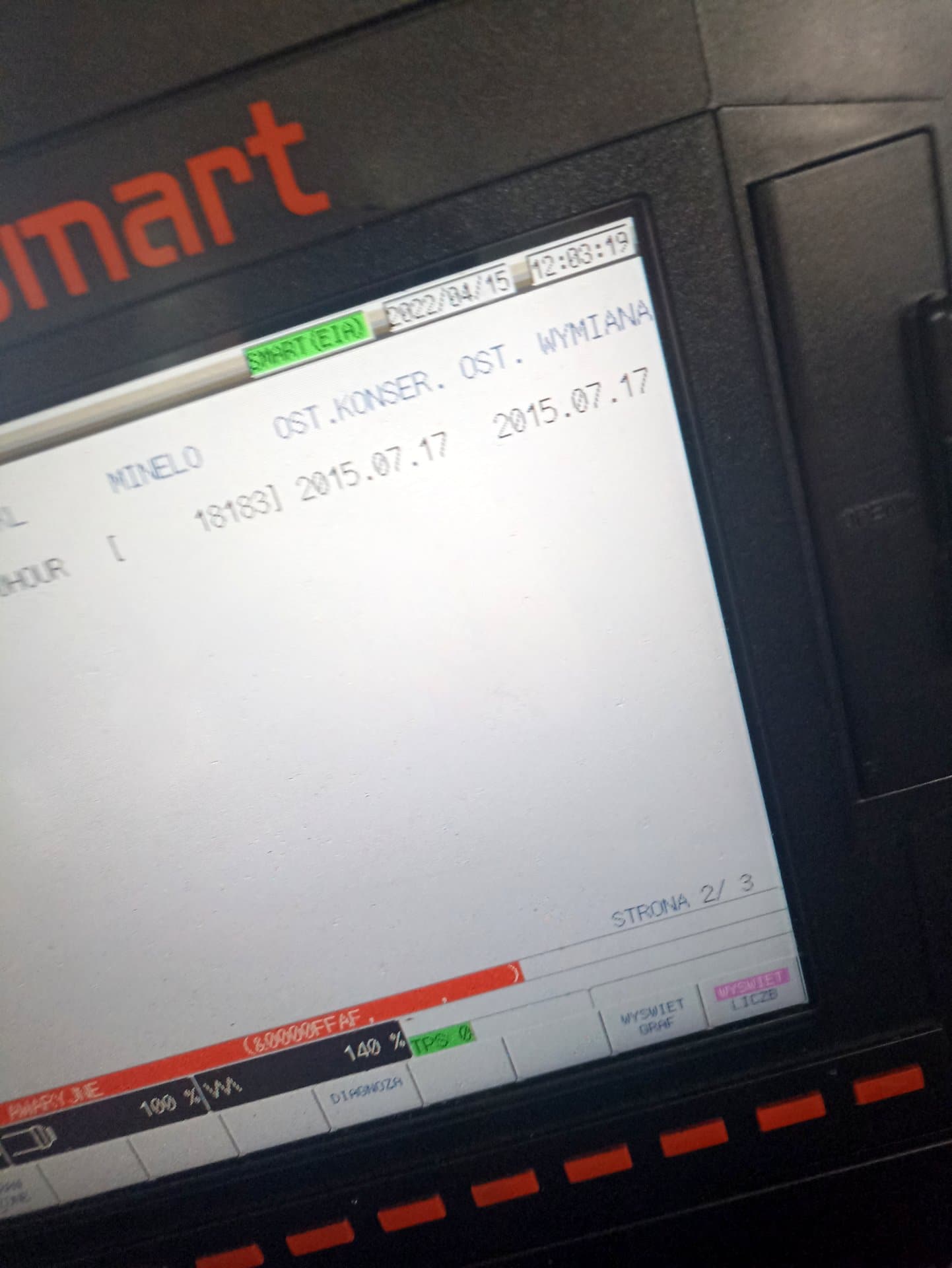

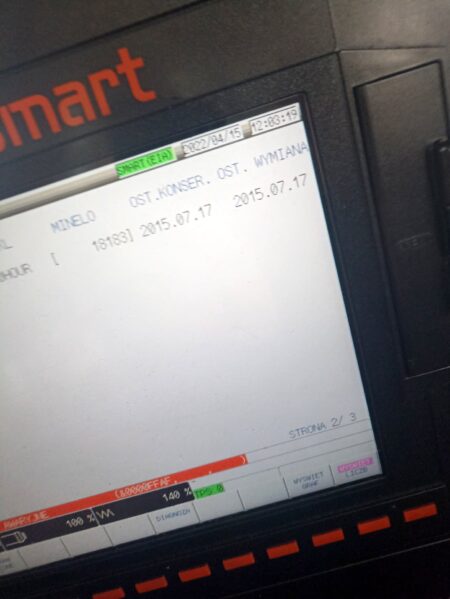

Full control of the workpiece machining is ensured by an installed MAZATROL Smart CNC controller with a large control panel, allowing support for G CODE commands, which are used to initiate axis movements, change feed rates, etc. The CNC lathe is equipped among others with a turret magazine capable of holding 12 tools, a chip conveyor and a Kitagawa B-20B chuck. The lathe has so far been used for one type of product. Total weight of the machine is 4500 kg.

Specification of MAZAK QUICK TURN SMART 200L lathe

- CNC controller: MAZATROL Smart

- feeds in X/Z axis: 195/560 mm

- rapid feeds in X/Z axes: 30/33 m/s

- maximum turning diameter: 350 mm

- maximum workpiece weight: 20 kg

- number of tool heads: 1 pcs.

- maximum number of tools in the turret: 12 pcs.

- maximum spindle speed: 5000 rpm

- chuck: Kitagawa B-20B

- type of spindle chuck: sleeve

- main spindle chuck size: 8″

- chip conveyor

- set of 4-5 toolholders

- man-hours: 18183 h

- total power requirement: 29 kVA

- power supply: 400 V; 50/60 Hz

- machine dimensions (L x W x H): 2650 x 1700 x 1700 mm

- weight: 4500 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe