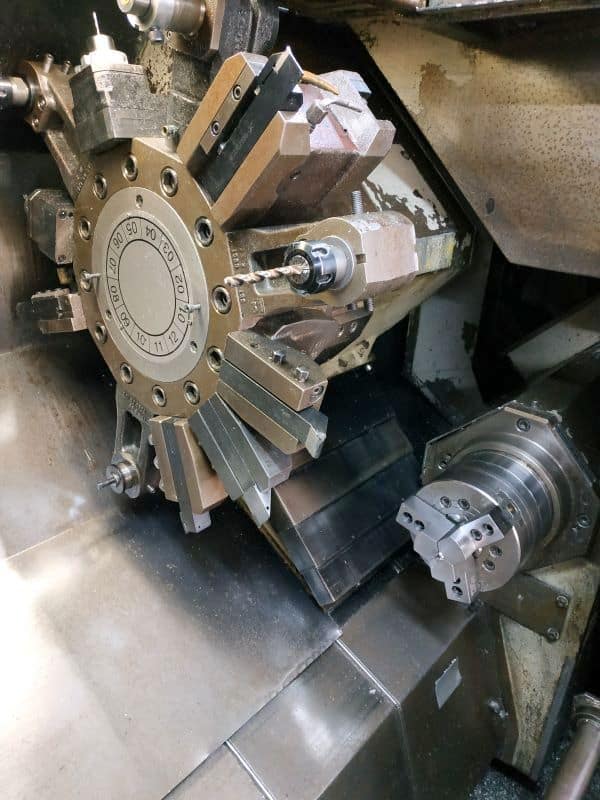

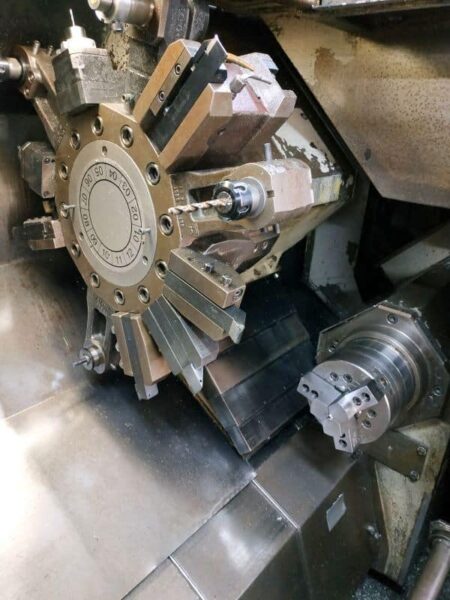

MAZAK SQT 15MS CNC turning center built in 1992 in Japan, is the best choice for any manufacturing facility. All of this is due to the 12-position toolhead and two powerful spindles (main spindle and sub-spindle) that maximise turning efficiency while maintaining high accuracy and precision. There is also an easy-to-use MAZATROL T32-3 CNC controller with a colour screen through which all machining parameters are programmed in just a few steps. The total weight of the machine is 4700 kg.

Technical specifications of the MAZAK SQT 15MS CNC lathe

General data

- feed rate in X/Z axis: 180/575 mm

- maximum workpiece diameter: 300 mm

- maximum workpiece length: 531 mm

- bar diameter: 51 mm

- X-axis positioning accuracy: ± 0.002 mm

- Z-axis positioning accuracy: ± 7 s

- C-axis positioning accuracy: ± 0.003 mm

- tool clamping force: 42140 N

- tool head indexing time: 1.4 s/full step

- air pressure: 490 KPa

- air consumption: 100 NL/min

- coolant tank capacity: 200 l

- hydraulic oil tank capacity: 45 l

- lubricant tank capacity: 1.8 l

- dimensions (L x W x H): 3055 x 1580 x 1900 mm

- space requirement: 4,8 m2

- weight of machine: 4700 kg

Main spindle

- main spindle rotational speed range: 35-5000 rpm

- bore diameter: 61 mm

- spindle nose: A2-6

- distance between spindle nose and tool head face end: 125-700 mm

- bearing diameter (front): 100 mm

- bearing diameter (rear): 80 mm

- torque: 294 Nm

- main spindle power (30 min/constant operation): 18.5/15 kW

Sub-spindle

- sub-spindle rotational speed range: 180-5000 rpm

- bore diameter: 31 mm

- spindle nose: A2-6

- bearing diameter (front): 80 mm

- bearing diameter (rear): 50 mm

- torque: 49 Nm

- sub-spindle power (10 min/constant operation): 7.5/10 kW

Equipment of the Super Quick Turn 15MS CNC dual-spindle lathe

- CNC control: MAZATROL T32-3

- foot controller

- sub-spindle

- 12-position tool head

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe